Key Insights

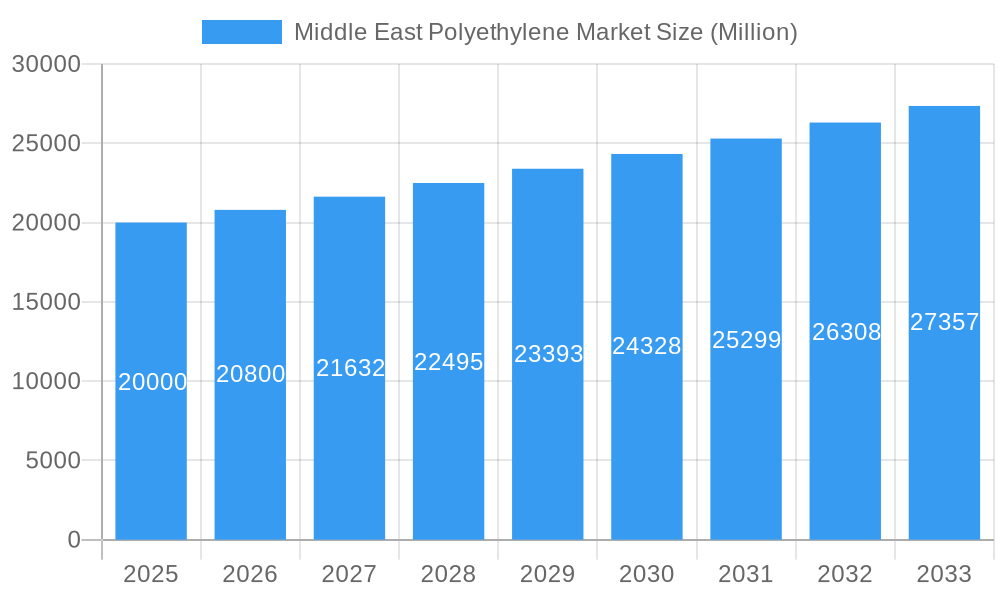

The Middle East Polyethylene Market is poised for robust expansion, projected to exceed an estimated XX million USD by 2025, with a Compound Annual Growth Rate (CAGR) exceeding 4.00% through 2033. This growth is primarily propelled by escalating demand from the packaging sector, which accounts for a significant portion of polyethylene consumption. The region's strategic investments in petrochemical infrastructure, coupled with its abundant hydrocarbon resources, provide a strong foundation for sustained production and market development. Furthermore, the burgeoning construction industry, driven by ambitious infrastructure projects and urban development initiatives, is another key driver, increasing the demand for polyethylene in pipes, conduit, and building materials. The increasing adoption of advanced manufacturing techniques, such as injection molding and films and sheets production, is further contributing to the market's upward trajectory, enabling the creation of diverse and high-performance polyethylene products.

Middle East Polyethylene Market Market Size (In Billion)

The market's dynamism is further shaped by evolving trends, including the growing emphasis on sustainability and the development of advanced polyethylene grades with enhanced properties. While the market benefits from strong demand drivers, it also faces certain restraints, such as fluctuating raw material prices and increasing regulatory scrutiny regarding plastic waste management. Despite these challenges, the Middle East polyethylene market is expected to witness steady growth, fueled by innovation and strategic market positioning by key players like Exxon Mobil Corporation, SABIC, and Dow. The region's strategic location and its role as a global supplier of petrochemicals will continue to underpin its significance in the global polyethylene landscape, with Saudi Arabia emerging as a dominant force within the Middle Eastern market.

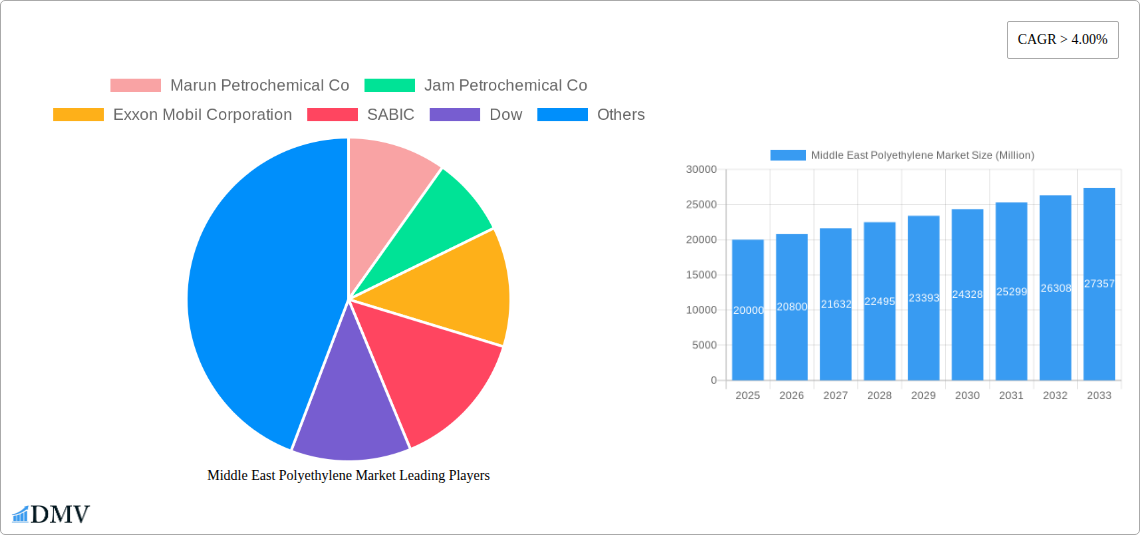

Middle East Polyethylene Market Company Market Share

This in-depth report offers a definitive analysis of the Middle East Polyethylene Market, providing critical insights and strategic guidance for stakeholders. Covering the study period from 2019 to 2033, with a base year of 2025 and a detailed forecast from 2025 to 2033, this report delves into market dynamics, growth drivers, challenges, and future opportunities. We meticulously examine key segments including product types (HDPE, LDPE, LLDPE, Other Product Types), applications (Blow Molding, Films and Sheets, Injection Molding, Pipes and Conduit, Wires and Cables, Other Applications), and end-user industries (Packaging, Transportation, Electrical and Electronics, Building and Construction, Agriculture, Other End-user Industries).

Middle East Polyethylene Market Market Composition & Trends

The Middle East Polyethylene Market is characterized by a moderate concentration, with key players like SABIC and Dow wielding significant influence. Innovation catalysts are primarily driven by the region's vast petrochemical resources and strategic investments in downstream processing. The regulatory landscape is supportive of industrial growth, encouraging capacity expansions and technological advancements. Substitute products, such as polypropylene and other polymers, present a competitive challenge, necessitating continuous product development and cost optimization. End-user profiles reveal a strong reliance on the burgeoning Packaging sector, followed by Building and Construction and Transportation. Mergers and Acquisitions (M&A) activities, while not pervasive, have historically focused on consolidation and vertical integration. Market share distribution in 2025 is estimated to be XXX Million for leading companies. M&A deal values in the historical period (2019-2024) averaged XXX Million, indicating strategic yet cautious consolidation. The pursuit of sustainable solutions and circular economy principles is emerging as a significant trend, influencing product development and investment strategies.

Middle East Polyethylene Market Industry Evolution

The Middle East Polyethylene Market has witnessed a robust evolutionary trajectory from 2019 to 2024, projecting sustained growth through 2033. This expansion is fundamentally underpinned by the region's strategic advantage in hydrocarbon feedstock availability, providing a cost-competitive edge for polyethylene production. Over the historical period, the market experienced a compounded annual growth rate (CAGR) of approximately XX% in terms of volume, reaching XXX Million tons in 2024. Technological advancements have been pivotal, with significant investments in state-of-the-art polymerization processes and catalyst technologies aimed at enhancing product quality, consistency, and the development of specialized grades. For instance, the adoption of advanced metallocene catalysts has enabled the production of high-performance LLDPE with superior mechanical properties, catering to sophisticated film applications. Shifting consumer demands, particularly in emerging economies within and beyond the Middle East, have fueled the need for versatile and sustainable polyethylene solutions. The increasing preference for lightweight, durable, and recyclable packaging materials, driven by environmental consciousness and regulatory pressures, has spurred innovation in film and sheet applications. Similarly, the growing infrastructure development and construction activities across the region have amplified the demand for robust polyethylene pipes and conduits, contributing significantly to market expansion. Furthermore, the burgeoning automotive and electronics sectors are increasingly incorporating polyethylene for its electrical insulation properties and lightweight characteristics, creating new avenues for market growth. The strategic focus on value-added downstream products, moving beyond commodity grades, is another key evolutionary aspect, with producers investing in research and development to create specialized polyethylenes for niche applications, thereby enhancing their competitive positioning and profitability.

Leading Regions, Countries, or Segments in Middle East Polyethylene Market

The dominance in the Middle East Polyethylene Market is multifaceted, with distinct leadership emerging across various segments.

Product Type Dominance:

- HDPE (High-Density Polyethylene): This segment holds a significant market share, driven by its exceptional strength, rigidity, and chemical resistance.

- Key Drivers: Robust demand from the Packaging (bottles, drums), Building and Construction (pipes, geomembranes), and Transportation (fuel tanks) sectors. Investment trends show substantial capacity expansions for HDPE production by major regional players. Regulatory support for durable goods manufacturing further bolsters its position.

- LLDPE (Linear Low-Density Polyethylene): LLDPE is experiencing rapid growth due to its flexibility, toughness, and puncture resistance.

- Key Drivers: Dominant in Films and Sheets for flexible packaging, agricultural films, and industrial wrapping. Technological advancements in LLDPE production, particularly with metallocene catalysts, are enhancing its performance and expanding its application range. The growing e-commerce sector fuels demand for high-performance packaging films.

- LDPE (Low-Density Polyethylene): While facing some competition from LLDPE, LDPE remains crucial for specific applications.

- Key Drivers: Essential for flexible films, coatings, and extrusions where clarity and ease of processing are paramount. Its use in Wires and Cables insulation and for certain Injection Molding applications ensures continued demand.

Application Dominance:

- Films and Sheets: This application segment is the largest contributor to the Middle East Polyethylene Market, reflecting the ubiquitous use of polyethylene films.

- Key Drivers: The insatiable demand from the Packaging industry for food packaging, industrial wraps, and consumer goods. Growth in Agriculture for greenhouse films and mulch films also plays a crucial role. Innovations in film technology, such as barrier properties and enhanced strength, are driving further adoption.

- Packaging: As an end-user industry, Packaging is the primary driver of polyethylene demand.

- Key Drivers: The expanding population and rising disposable incomes across the Middle East and North Africa (MENA) region fuel consumption of packaged goods. Investments in food processing and retail infrastructure further enhance the need for diverse packaging solutions.

End-user Industry Dominance:

- Packaging: This industry represents the most significant consumer of polyethylene.

- Key Drivers: The strong growth of the food and beverage sector, driven by population expansion and changing consumer lifestyles. The e-commerce boom necessitates lightweight, durable, and cost-effective packaging solutions. Regulatory initiatives promoting food safety and shelf-life extension also contribute to demand.

- Building and Construction: This sector is a major consumer of polyethylene for infrastructure development.

- Key Drivers: Government-led infrastructure projects, urbanization, and the demand for durable and corrosion-resistant piping systems are substantial growth catalysts. Polyethylene's role in water and sewage management systems is critical.

Middle East Polyethylene Market Product Innovations

Product innovations in the Middle East Polyethylene Market are increasingly focused on enhancing performance, sustainability, and specialized applications. Advancements in catalyst technology have led to the development of metallocene-based LLDPE grades offering superior tear strength and puncture resistance for demanding film applications. Innovations in HDPE are geared towards improved stress crack resistance and enhanced processability for intricate injection molding and extrusion applications. Furthermore, the market is witnessing a surge in the development of recycled polyethylene content grades and bio-based polyethylene alternatives, addressing the growing demand for sustainable packaging solutions. Performance metrics like improved melt flow rates, enhanced barrier properties, and increased durability are key selling propositions for these new materials.

Propelling Factors for Middle East Polyethylene Market Growth

The Middle East Polyethylene Market's growth is propelled by a confluence of powerful factors. The region's abundant and cost-competitive feedstock availability remains a fundamental advantage. Significant government initiatives aimed at diversifying economies and developing downstream petrochemical industries foster continuous investment in new capacities and technological upgrades. Rapid urbanization and population growth, particularly in emerging economies, are escalating demand from key end-user industries like Packaging and Building & Construction. Furthermore, ongoing technological advancements in polymerization processes and product development are enabling the creation of high-performance, specialized polyethylene grades that cater to evolving market needs and applications, such as lightweight automotive components and advanced flexible packaging.

Obstacles in the Middle East Polyethylene Market Market

Despite robust growth, the Middle East Polyethylene Market faces several obstacles. Volatility in global oil and gas prices can directly impact feedstock costs, influencing production economics and market competitiveness. Increasing global competition from other polyethylene-producing regions, particularly Asia, presents a challenge. Supply chain disruptions, exacerbated by geopolitical events and logistical complexities, can affect raw material procurement and finished product distribution. Furthermore, growing environmental regulations and public pressure regarding plastic waste are driving the need for more sustainable solutions, requiring significant investment in recycling infrastructure and the development of circular economy models, which can be a barrier to adoption for some traditional players.

Future Opportunities in Middle East Polyethylene Market

Future opportunities in the Middle East Polyethylene Market lie in the burgeoning demand for specialized and high-performance polyethylene grades. The growing focus on sustainability presents significant opportunities for manufacturers developing bio-based and recycled polyethylene materials. The expanding e-commerce sector will continue to drive demand for advanced flexible packaging solutions. Furthermore, untapped potential exists in emerging applications within the automotive, medical, and renewable energy sectors, requiring tailored polyethylene properties. Investments in downstream processing and the development of innovative product designs will unlock new market segments and revenue streams for agile players.

Major Players in the Middle East Polyethylene Market Ecosystem

- Marun Petrochemical Co

- Jam Petrochemical Co

- Exxon Mobil Corporation

- SABIC

- Dow

- Saudi Polymers Company (Chevron & SABIC)

- Amir Kabir Petrochemical Co (AKPC)

- Ilam Petrochemical

- Saudi Ethylene and Polyethylene Co (Tasnee)

- Sharq - Eastern Petrochemical Co (SDPC)

- LyondellBasell Industries Holdings BV

Key Developments in Middle East Polyethylene Market Industry

- November 2022: SABIC partnered with Guangdong Jinming Machinery Co. Ltd, a plastic packaging equipment manufacturer, and Bolsas de los Altos, a leading plastic film and packaging converter. The agreement will allow SABIC polyolefin resin products, as well as polyethylene resin offers from Gulf Coast Growth Ventures (GCGV) and TRUCIRCLETM, to be tested and validated. This development signifies SABIC's commitment to fostering collaboration across the value chain and accelerating the validation of innovative polyolefin solutions.

- September 2021: SABIC announced the development of a new technology and range of dedicated polyethylene (PE) and polypropylene (PP) resins that represent a substantial advancement in the performance profile of polyolefin pressure pipes. The technique is being developed from concept to reality in collaboration with Tecnomatic and aquatherm, two key specialists in pipe manufacture. This initiative highlights SABIC's focus on enhancing material performance for critical infrastructure applications and strengthening its position in the piping sector.

Strategic Middle East Polyethylene Market Market Forecast

The Middle East Polyethylene Market is poised for continued robust growth, projected to reach XXX Million by 2033. This expansion will be fueled by ongoing capacity additions, technological innovations, and a deepening focus on value-added products. The increasing demand for sustainable polyethylene solutions, including recycled and bio-based materials, will present significant strategic opportunities for market players. Furthermore, the region's favorable feedstock economics and governmental support for downstream industries will continue to attract investment, solidifying its position as a global polyethylene hub. Emerging applications in specialized sectors and the ongoing development of high-performance grades will drive market diversification and profitability.

Middle East Polyethylene Market Segmentation

-

1. Product Type

- 1.1. HDPE

- 1.2. LDPE

- 1.3. LLDPE

- 1.4. Other Product Types

-

2. Application

- 2.1. Blow Molding

- 2.2. Films and Sheets

- 2.3. Injection Molding

- 2.4. Pipes and Conduit

- 2.5. Wires and Cables

- 2.6. Other Applications

-

3. End-user Industry

- 3.1. Packaging

- 3.2. Transportation

- 3.3. Electrical and Electronics

- 3.4. Building and Construction

- 3.5. Agriculture

- 3.6. Other End-user Industries

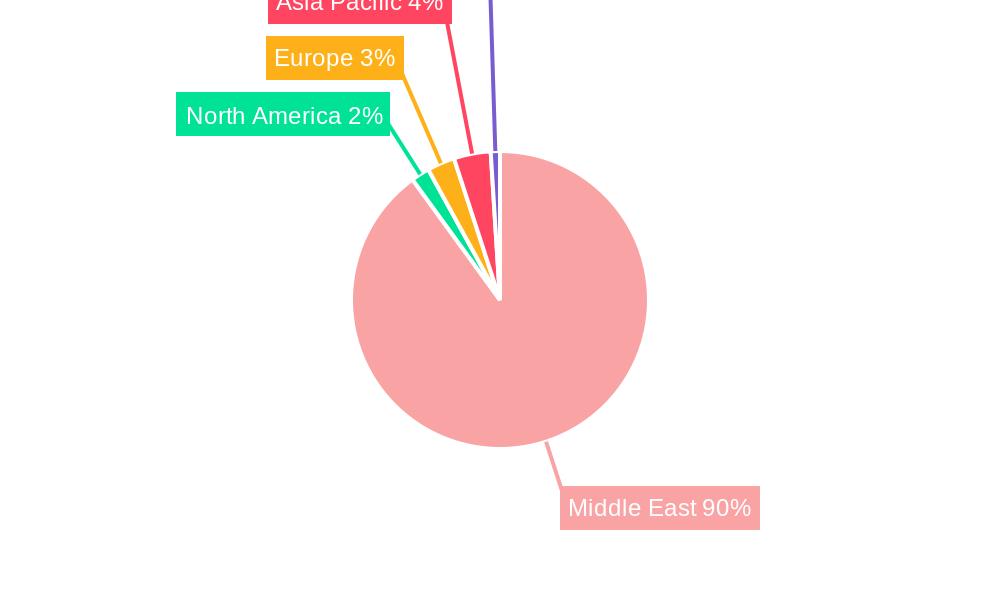

Middle East Polyethylene Market Segmentation By Geography

-

1. Middle East

- 1.1. Saudi Arabia

- 1.2. United Arab Emirates

- 1.3. Israel

- 1.4. Qatar

- 1.5. Kuwait

- 1.6. Oman

- 1.7. Bahrain

- 1.8. Jordan

- 1.9. Lebanon

Middle East Polyethylene Market Regional Market Share

Geographic Coverage of Middle East Polyethylene Market

Middle East Polyethylene Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 4.7% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Increasing Demand from a Diverse Range of End-user Industries; Growth in Industrial Applications such as Primarily Packing Automotive and Electrical Replacement Part

- 3.3. Market Restrains

- 3.3.1. Availability of Substitutes such as Polypropylene and Polyethylene Terephthalate Products; Other Restraints

- 3.4. Market Trends

- 3.4.1. Increasing Demand in the Building and Construction Industry

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Middle East Polyethylene Market Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Product Type

- 5.1.1. HDPE

- 5.1.2. LDPE

- 5.1.3. LLDPE

- 5.1.4. Other Product Types

- 5.2. Market Analysis, Insights and Forecast - by Application

- 5.2.1. Blow Molding

- 5.2.2. Films and Sheets

- 5.2.3. Injection Molding

- 5.2.4. Pipes and Conduit

- 5.2.5. Wires and Cables

- 5.2.6. Other Applications

- 5.3. Market Analysis, Insights and Forecast - by End-user Industry

- 5.3.1. Packaging

- 5.3.2. Transportation

- 5.3.3. Electrical and Electronics

- 5.3.4. Building and Construction

- 5.3.5. Agriculture

- 5.3.6. Other End-user Industries

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. Middle East

- 5.1. Market Analysis, Insights and Forecast - by Product Type

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 Marun Petrochemical Co

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 Jam Petrochemical Co

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 Exxon Mobil Corporation

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 SABIC

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 Dow

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Saudi Polymers Company (Chevron & SABIC)

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 Amir Kabir Petrochemical Co (AKPC)

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 Ilam Petrochemical

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 Saudi Ethylene and Polyethylene Co (Tasnee)

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.10 Sharq - Eastern Petrochemical Co (SDPC)

- 6.2.10.1. Overview

- 6.2.10.2. Products

- 6.2.10.3. SWOT Analysis

- 6.2.10.4. Recent Developments

- 6.2.10.5. Financials (Based on Availability)

- 6.2.11 LyondellBasell Industries Holdings BV

- 6.2.11.1. Overview

- 6.2.11.2. Products

- 6.2.11.3. SWOT Analysis

- 6.2.11.4. Recent Developments

- 6.2.11.5. Financials (Based on Availability)

- 6.2.1 Marun Petrochemical Co

List of Figures

- Figure 1: Middle East Polyethylene Market Revenue Breakdown (undefined, %) by Product 2025 & 2033

- Figure 2: Middle East Polyethylene Market Share (%) by Company 2025

List of Tables

- Table 1: Middle East Polyethylene Market Revenue undefined Forecast, by Product Type 2020 & 2033

- Table 2: Middle East Polyethylene Market Volume K Tons Forecast, by Product Type 2020 & 2033

- Table 3: Middle East Polyethylene Market Revenue undefined Forecast, by Application 2020 & 2033

- Table 4: Middle East Polyethylene Market Volume K Tons Forecast, by Application 2020 & 2033

- Table 5: Middle East Polyethylene Market Revenue undefined Forecast, by End-user Industry 2020 & 2033

- Table 6: Middle East Polyethylene Market Volume K Tons Forecast, by End-user Industry 2020 & 2033

- Table 7: Middle East Polyethylene Market Revenue undefined Forecast, by Region 2020 & 2033

- Table 8: Middle East Polyethylene Market Volume K Tons Forecast, by Region 2020 & 2033

- Table 9: Middle East Polyethylene Market Revenue undefined Forecast, by Product Type 2020 & 2033

- Table 10: Middle East Polyethylene Market Volume K Tons Forecast, by Product Type 2020 & 2033

- Table 11: Middle East Polyethylene Market Revenue undefined Forecast, by Application 2020 & 2033

- Table 12: Middle East Polyethylene Market Volume K Tons Forecast, by Application 2020 & 2033

- Table 13: Middle East Polyethylene Market Revenue undefined Forecast, by End-user Industry 2020 & 2033

- Table 14: Middle East Polyethylene Market Volume K Tons Forecast, by End-user Industry 2020 & 2033

- Table 15: Middle East Polyethylene Market Revenue undefined Forecast, by Country 2020 & 2033

- Table 16: Middle East Polyethylene Market Volume K Tons Forecast, by Country 2020 & 2033

- Table 17: Saudi Arabia Middle East Polyethylene Market Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 18: Saudi Arabia Middle East Polyethylene Market Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 19: United Arab Emirates Middle East Polyethylene Market Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 20: United Arab Emirates Middle East Polyethylene Market Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 21: Israel Middle East Polyethylene Market Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 22: Israel Middle East Polyethylene Market Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 23: Qatar Middle East Polyethylene Market Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 24: Qatar Middle East Polyethylene Market Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 25: Kuwait Middle East Polyethylene Market Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 26: Kuwait Middle East Polyethylene Market Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 27: Oman Middle East Polyethylene Market Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 28: Oman Middle East Polyethylene Market Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 29: Bahrain Middle East Polyethylene Market Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 30: Bahrain Middle East Polyethylene Market Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 31: Jordan Middle East Polyethylene Market Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 32: Jordan Middle East Polyethylene Market Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 33: Lebanon Middle East Polyethylene Market Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 34: Lebanon Middle East Polyethylene Market Volume (K Tons) Forecast, by Application 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Middle East Polyethylene Market?

The projected CAGR is approximately 4.7%.

2. Which companies are prominent players in the Middle East Polyethylene Market?

Key companies in the market include Marun Petrochemical Co, Jam Petrochemical Co, Exxon Mobil Corporation, SABIC, Dow, Saudi Polymers Company (Chevron & SABIC), Amir Kabir Petrochemical Co (AKPC), Ilam Petrochemical, Saudi Ethylene and Polyethylene Co (Tasnee), Sharq - Eastern Petrochemical Co (SDPC), LyondellBasell Industries Holdings BV.

3. What are the main segments of the Middle East Polyethylene Market?

The market segments include Product Type, Application, End-user Industry.

4. Can you provide details about the market size?

The market size is estimated to be USD XXX N/A as of 2022.

5. What are some drivers contributing to market growth?

Increasing Demand from a Diverse Range of End-user Industries; Growth in Industrial Applications such as Primarily Packing Automotive and Electrical Replacement Part.

6. What are the notable trends driving market growth?

Increasing Demand in the Building and Construction Industry.

7. Are there any restraints impacting market growth?

Availability of Substitutes such as Polypropylene and Polyethylene Terephthalate Products; Other Restraints.

8. Can you provide examples of recent developments in the market?

November 2022: SABIC partnered with Guangdong Jinming Machinery Co. Ltd, a plastic packaging equipment manufacturer, and Bolsas de los Altos, a leading plastic film and packaging converter. The agreement will allow SABIC polyolefin resin products, as well as polyethylene resin offers from Gulf Coast Growth Ventures (GCGV) and TRUCIRCLETM, to be tested and validated.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 4950, and USD 6800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in N/A and volume, measured in K Tons.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Middle East Polyethylene Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Middle East Polyethylene Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Middle East Polyethylene Market?

To stay informed about further developments, trends, and reports in the Middle East Polyethylene Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence