Key Insights

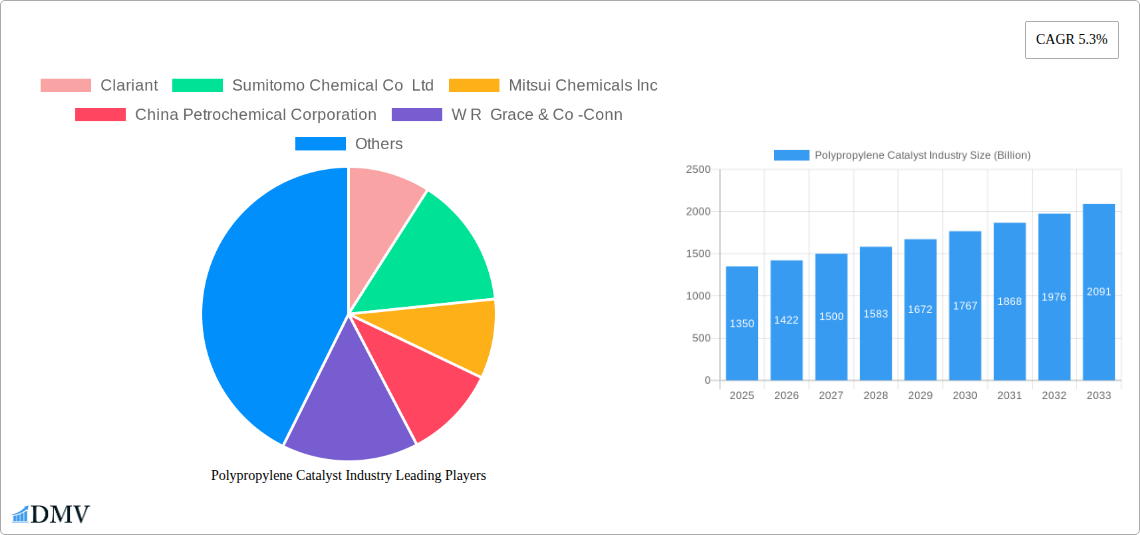

The polypropylene catalyst market, valued at $1.35 billion in 2025, is projected to experience robust growth, driven by the increasing demand for polypropylene in diverse applications across packaging, automotive, textiles, and healthcare. A compound annual growth rate (CAGR) of 5.3% from 2025 to 2033 signifies a substantial market expansion. Key growth drivers include the rising global population, escalating consumer spending, and the lightweighting trend in the automotive industry, pushing the need for high-performance polypropylene. Technological advancements in catalyst design, such as the development of metallocene catalysts offering improved polymer properties like enhanced strength and flexibility, are further stimulating market expansion. The market is segmented by catalyst type (Ziegler-Natta and metallocene), production process (bulk, gas-phase, and slurry), and application. While Ziegler-Natta catalysts currently dominate due to their cost-effectiveness, metallocene catalysts are gaining traction owing to their ability to produce tailored polypropylene grades. The gas-phase process holds a significant market share due to its high efficiency and product quality. Regionally, Asia-Pacific is expected to lead the market, fueled by rapid industrialization and increasing polypropylene consumption in developing economies like China and India. However, stringent environmental regulations in developed regions might pose challenges, necessitating the adoption of sustainable production practices.

Polypropylene Catalyst Industry Market Size (In Billion)

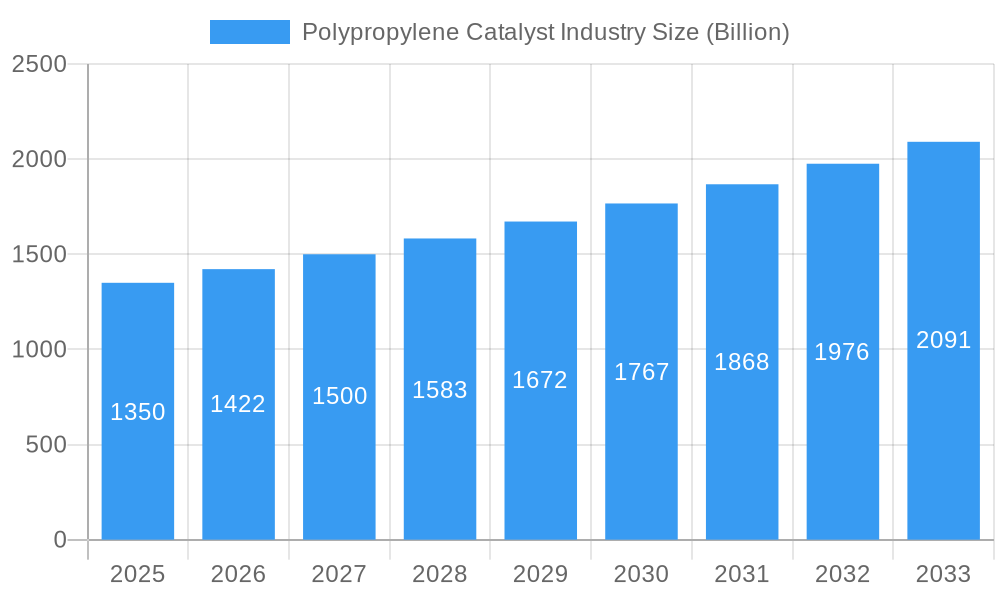

The competitive landscape is characterized by the presence of both established chemical giants and specialized catalyst manufacturers. Companies such as Clariant, Sumitomo Chemical, Mitsui Chemicals, and others are actively engaged in research and development, focusing on innovation to cater to evolving market needs. The market faces restraints such as fluctuating raw material prices and potential economic downturns that could impact polypropylene demand. However, the long-term outlook remains positive, driven by the increasing application scope of polypropylene and ongoing technological progress in catalyst manufacturing. The shift towards sustainable and environmentally friendly production methods is also expected to shape the future of the polypropylene catalyst industry, driving the adoption of greener catalysts and processes.

Polypropylene Catalyst Industry Company Market Share

Polypropylene Catalyst Industry: A Comprehensive Market Report (2019-2033)

This insightful report provides a comprehensive analysis of the global Polypropylene Catalyst industry, offering a detailed overview of market dynamics, competitive landscape, and future growth prospects. Valued at billions of dollars, the Polypropylene Catalyst market is experiencing significant transformation driven by technological advancements and evolving consumer demands. This report serves as an essential resource for stakeholders seeking to navigate this dynamic industry landscape. The study period spans from 2019 to 2033, with 2025 serving as the base and estimated year. The forecast period covers 2025-2033 and the historical period encompasses 2019-2024.

Polypropylene Catalyst Industry Market Composition & Trends

The Polypropylene Catalyst market, estimated at $XX Billion in 2025, exhibits a moderately concentrated landscape. Key players, including Clariant, Sumitomo Chemical Co Ltd, Mitsui Chemicals Inc, China Petrochemical Corporation, W R Grace & Co -Conn, INEOS, Reliance Industries Limited, LyondellBasell Industries Holdings B V, Univation Technologies LLC, TOHO TITANIUM CO LTD, and Albemarle Corporation, hold significant market share. Market share distribution varies significantly based on catalyst type and production process, with Ziegler-Natta catalysts dominating the market. Innovation is driven by the pursuit of higher catalyst activity, improved selectivity, and reduced production costs. Stringent environmental regulations are shaping industry practices, promoting the adoption of greener catalyst technologies. Substitute products, such as metallocene catalysts, are gaining traction, impacting the market share of traditional Ziegler-Natta catalysts. End-user demand is primarily driven by the polypropylene industry, with various sectors, including packaging, automotive, and consumer goods, significantly contributing to overall market size. M&A activities, though not frequent, play a crucial role in shaping market dynamics. Recent deals have averaged $XX Billion in value, reflecting industry consolidation.

- Market Concentration: Moderately concentrated with top 10 players controlling approximately XX% of the market.

- Innovation Catalysts: Demand for high-efficiency catalysts, sustainable production processes, and cost reduction.

- Regulatory Landscape: Stringent environmental regulations promoting the development and adoption of eco-friendly catalysts.

- Substitute Products: Metallocene catalysts pose a significant competitive challenge to traditional Ziegler-Natta catalysts.

- End-User Profiles: Packaging, automotive, and consumer goods industries are major end-users.

- M&A Activities: Recent deals valued at an average of $XX Billion show signs of industry consolidation.

Polypropylene Catalyst Industry Evolution

The global Polypropylene Catalyst market has witnessed consistent growth over the historical period (2019-2024), with a Compound Annual Growth Rate (CAGR) of XX%. This growth is primarily attributed to the rising demand for polypropylene across various end-use sectors. Technological advancements, particularly in metallocene catalyst technology, have significantly influenced market dynamics. The shift towards more efficient and environmentally friendly production processes has also played a crucial role. Consumer demand for high-quality, cost-effective polypropylene products fuels the growth of the catalyst market. The adoption of gas-phase and slurry-phase processes is gradually increasing, replacing bulk processes in certain applications. The market is expected to maintain a steady growth trajectory during the forecast period (2025-2033), with a projected CAGR of XX%, driven by factors such as increasing global polypropylene production, the development of novel catalyst technologies, and the rising demand for sustainable materials in various industries. Specific data on growth rates and adoption metrics for newer technologies is proprietary and cannot be shared.

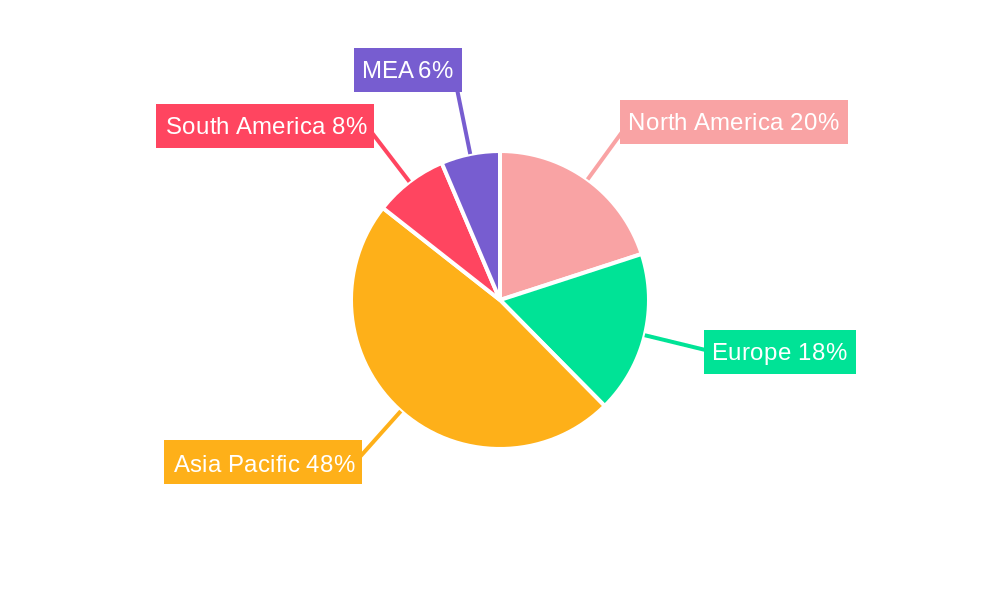

Leading Regions, Countries, or Segments in Polypropylene Catalyst Industry

The **Asia-Pacific region** continues to lead the global Polypropylene Catalyst market, propelled by robust industrial expansion and escalating polypropylene production across major economies like China, India, and Southeast Asian nations. This dominance is fueled by substantial investments in new and upgraded polymerization facilities, coupled with supportive government policies promoting manufacturing and economic growth. Within catalyst technologies, **Ziegler-Natta catalysts** maintain their strong market position due to their proven reliability, cost-effectiveness, and widespread application in established polypropylene grades. However, **metallocene catalysts** are steadily gaining traction, offering superior control over polymer architecture, leading to enhanced performance characteristics for specialized applications. In terms of process technologies, the **gas-phase polymerization process** is experiencing significant growth. Its inherent advantages, including higher reactor productivity, improved energy efficiency, and reduced environmental impact through lower solvent usage, make it increasingly attractive for large-scale polypropylene production. The **polypropylene application segment** overwhelmingly represents the largest share of catalyst consumption, as polypropylene remains a cornerstone material in a vast array of industries.

- Key Drivers for Asia-Pacific Dominance:

- Unprecedented investments in expanding and modernizing polypropylene production capacities to meet surging domestic and export demand.

- Favorable government initiatives and industrial policies aimed at fostering self-sufficiency and global competitiveness in petrochemicals.

- Rapid expansion of downstream industries, particularly in packaging (flexible and rigid), automotive components, textiles, and consumer goods, which are major consumers of polypropylene.

- Growing urbanization and rising disposable incomes in emerging economies, driving demand for packaged goods and durable products.

- Ziegler-Natta Catalyst Dominance:

- Long-standing history of reliable performance and established manufacturing processes.

- Cost-effectiveness compared to more advanced catalyst systems, making them the preferred choice for commodity polypropylene grades.

- Versatility in producing a wide range of polypropylene homopolymers, copolymers, and random copolymers.

- Metallocene Catalyst Growth:

- Ability to produce polypropylene with precisely controlled molecular weight distribution, tacticity, and comonomer incorporation.

- Enables the creation of high-performance polypropylene grades with enhanced clarity, impact strength, melt strength, and thermal resistance for specialized applications.

- Increasing adoption in advanced packaging solutions, automotive interiors, and medical devices.

- Gas-Phase Process Growth:

- Superior reactor economics due to higher throughput and lower capital expenditure per ton of polymer produced.

- Reduced environmental footprint through the elimination or significant reduction of liquid diluents, leading to lower VOC emissions and waste generation.

- Enhanced operational flexibility for producing a diverse range of polypropylene grades within the same reactor system.

- Improved product quality and consistency due to better heat transfer and mass transfer characteristics.

- Polypropylene Application:

- Polypropylene remains one of the most widely produced and consumed polymers globally.

- Its applications span across diverse sectors including packaging (films, containers, closures), automotive (bumpers, dashboards, interior trim), textiles (fibers, nonwovens), construction (pipes, insulation), and consumer goods (appliances, furniture, toys).

- This broad spectrum of end-uses drives continuous demand for polypropylene catalysts.

Polypropylene Catalyst Industry Product Innovations

Recent innovations in polypropylene catalysts focus on enhancing catalyst activity, improving polymer properties, and reducing environmental impact. New generation Ziegler-Natta catalysts offer higher productivity and better control over polymer microstructure. Metallocene catalysts are being developed with improved stereoselectivity and broader applicability. The focus on sustainability is driving the development of catalysts with enhanced energy efficiency and reduced waste generation. These advancements are leading to the production of higher-performance polypropylene with enhanced properties, such as improved strength, stiffness, and processability.

Propelling Factors for Polypropylene Catalyst Growth

The Polypropylene Catalyst market's growth is propelled by several factors: the burgeoning global demand for polypropylene, particularly in packaging and automotive applications; continuous technological advancements resulting in enhanced catalyst efficiency and performance; and favorable government policies supporting industrial growth and sustainable manufacturing.

Obstacles in the Polypropylene Catalyst Market

Challenges include intense competition from established players, potential supply chain disruptions affecting raw material availability, and stringent environmental regulations necessitating costly upgrades to manufacturing facilities. Fluctuations in crude oil prices also impact polypropylene production costs and, in turn, catalyst demand.

Future Opportunities in Polypropylene Catalyst Industry

The future landscape of the Polypropylene Catalyst industry is ripe with opportunities centered on innovation, sustainability, and market expansion. A primary focus will be the development of **next-generation catalyst technologies** that offer significantly enhanced performance characteristics, such as improved stereospecificity for higher-purity polymers, increased catalyst activity for higher production yields, and tailored functionalities for specific end-use requirements. This includes exploring novel catalyst materials, advanced support systems, and innovative catalyst preparation techniques. Sustainability will be a pivotal driver, with substantial opportunities in creating catalysts that enable the production of polypropylene from renewable feedstocks, facilitate easier recycling, or lead to lighter-weight products thereby reducing material consumption. Furthermore, the development of catalysts optimized for producing **bioplastics and biodegradable polypropylene alternatives** presents a significant growth avenue. Expanding market penetration into **emerging economies** with underdeveloped petrochemical infrastructure and growing consumer bases also offers considerable potential. Companies that can offer cost-effective, high-performance, and environmentally conscious catalyst solutions will be well-positioned to capture these future opportunities.

Major Players in the Polypropylene Catalyst Industry Ecosystem

- Clariant

- Sumitomo Chemical Co Ltd

- Mitsui Chemicals Inc

- China Petrochemical Corporation

- W R Grace & Co -Conn

- INEOS

- Reliance Industries Limited

- LyondellBasell Industries Holdings B V

- Univation Technologies LLC

- TOHO TITANIUM CO LTD

- Albemarle Corporation

Key Developments in Polypropylene Catalyst Industry

- 2022 Q3: Clariant launched a new generation of Ziegler-Natta catalyst, branded as "Hostalen," designed to deliver enhanced efficiency and improved polymer properties for a wide range of polypropylene grades.

- 2023 Q1: Sumitomo Chemical announced a strategic partnership with a leading European petrochemical company to accelerate the research and development of sustainable catalyst technologies, with a focus on catalysts that enable lower energy consumption and reduced emissions during polypropylene production.

- 2024 Q2: Mitsui Chemicals announced a significant investment in a new state-of-the-art polypropylene production facility. This facility is engineered to incorporate advanced catalyst technology, including proprietary metallocene catalysts, to produce high-performance polypropylene for the automotive and packaging sectors. (Further specific developments related to proprietary technologies are confidential and not publicly disclosed.)

- Ongoing Research: Active research is underway across major catalyst manufacturers to develop catalysts that can effectively produce polypropylene with a higher percentage of recycled content, contributing to circular economy initiatives.

- Emerging Trends: Focus on catalysts enabling inline modification of polymer properties, reducing the need for post-polymerization compounding and enhancing production efficiency.

Strategic Polypropylene Catalyst Market Forecast

The Polypropylene Catalyst market is poised for robust growth in the coming years, driven by the expanding global demand for polypropylene, continuous innovation in catalyst technology, and supportive government policies. The focus on sustainability and the development of high-performance catalysts will be key factors shaping the market's future. The market is expected to reach $XX Billion by 2033, presenting significant opportunities for established players and new entrants.

Polypropylene Catalyst Industry Segmentation

-

1. Type

- 1.1. Ziegler Natta Catalyst

- 1.2. Metallocene Catalyst

-

2. Production Process

- 2.1. Bulk Process

- 2.2. Gas-Phase Process

- 2.3. Slurry Phase

-

3. Application

- 3.1. Polypropylene

- 3.2. Others

Polypropylene Catalyst Industry Segmentation By Geography

-

1. Asia Pacific

- 1.1. China

- 1.2. India

- 1.3. Japan

- 1.4. South Korea

- 1.5. Rest of Asia Pacific

-

2. North America

- 2.1. United States

- 2.2. Canada

- 2.3. Mexico

-

3. Europe

- 3.1. Germany

- 3.2. United Kingdom

- 3.3. France

- 3.4. Italy

- 3.5. Rest of Europe

-

4. South America

- 4.1. Brazil

- 4.2. Argentina

- 4.3. Rest of South America

-

5. Middle East and Africa

- 5.1. Saudi Arabia

- 5.2. South Africa

- 5.3. Rest of Middle East and Africa

Polypropylene Catalyst Industry Regional Market Share

Geographic Coverage of Polypropylene Catalyst Industry

Polypropylene Catalyst Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 5.3% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. ; Growing Demand of Polypropylene Catalyst from Manufacturing of Polypropylene; Other Drivers

- 3.3. Market Restrains

- 3.3.1. ; Government Regulation on Use of Polypropylene Catalyst; Other Restraints

- 3.4. Market Trends

- 3.4.1. Growing Demand of Polypropylene Catalyst from Manufacturing of Polypropylene

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Polypropylene Catalyst Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Type

- 5.1.1. Ziegler Natta Catalyst

- 5.1.2. Metallocene Catalyst

- 5.2. Market Analysis, Insights and Forecast - by Production Process

- 5.2.1. Bulk Process

- 5.2.2. Gas-Phase Process

- 5.2.3. Slurry Phase

- 5.3. Market Analysis, Insights and Forecast - by Application

- 5.3.1. Polypropylene

- 5.3.2. Others

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. Asia Pacific

- 5.4.2. North America

- 5.4.3. Europe

- 5.4.4. South America

- 5.4.5. Middle East and Africa

- 5.1. Market Analysis, Insights and Forecast - by Type

- 6. Asia Pacific Polypropylene Catalyst Industry Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Type

- 6.1.1. Ziegler Natta Catalyst

- 6.1.2. Metallocene Catalyst

- 6.2. Market Analysis, Insights and Forecast - by Production Process

- 6.2.1. Bulk Process

- 6.2.2. Gas-Phase Process

- 6.2.3. Slurry Phase

- 6.3. Market Analysis, Insights and Forecast - by Application

- 6.3.1. Polypropylene

- 6.3.2. Others

- 6.1. Market Analysis, Insights and Forecast - by Type

- 7. North America Polypropylene Catalyst Industry Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Type

- 7.1.1. Ziegler Natta Catalyst

- 7.1.2. Metallocene Catalyst

- 7.2. Market Analysis, Insights and Forecast - by Production Process

- 7.2.1. Bulk Process

- 7.2.2. Gas-Phase Process

- 7.2.3. Slurry Phase

- 7.3. Market Analysis, Insights and Forecast - by Application

- 7.3.1. Polypropylene

- 7.3.2. Others

- 7.1. Market Analysis, Insights and Forecast - by Type

- 8. Europe Polypropylene Catalyst Industry Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Type

- 8.1.1. Ziegler Natta Catalyst

- 8.1.2. Metallocene Catalyst

- 8.2. Market Analysis, Insights and Forecast - by Production Process

- 8.2.1. Bulk Process

- 8.2.2. Gas-Phase Process

- 8.2.3. Slurry Phase

- 8.3. Market Analysis, Insights and Forecast - by Application

- 8.3.1. Polypropylene

- 8.3.2. Others

- 8.1. Market Analysis, Insights and Forecast - by Type

- 9. South America Polypropylene Catalyst Industry Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Type

- 9.1.1. Ziegler Natta Catalyst

- 9.1.2. Metallocene Catalyst

- 9.2. Market Analysis, Insights and Forecast - by Production Process

- 9.2.1. Bulk Process

- 9.2.2. Gas-Phase Process

- 9.2.3. Slurry Phase

- 9.3. Market Analysis, Insights and Forecast - by Application

- 9.3.1. Polypropylene

- 9.3.2. Others

- 9.1. Market Analysis, Insights and Forecast - by Type

- 10. Middle East and Africa Polypropylene Catalyst Industry Analysis, Insights and Forecast, 2020-2032

- 10.1. Market Analysis, Insights and Forecast - by Type

- 10.1.1. Ziegler Natta Catalyst

- 10.1.2. Metallocene Catalyst

- 10.2. Market Analysis, Insights and Forecast - by Production Process

- 10.2.1. Bulk Process

- 10.2.2. Gas-Phase Process

- 10.2.3. Slurry Phase

- 10.3. Market Analysis, Insights and Forecast - by Application

- 10.3.1. Polypropylene

- 10.3.2. Others

- 10.1. Market Analysis, Insights and Forecast - by Type

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2025

- 11.2. Company Profiles

- 11.2.1 Clariant

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Sumitomo Chemical Co Ltd

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 Mitsui Chemicals Inc

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 China Petrochemical Corporation

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 W R Grace & Co -Conn

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 INEOS

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 Reliance Industries Limited

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 LyondellBasell Industries Holdings B V

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 Univation Technologies LLC

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 TOHO TITANIUM CO LTD

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.11 Albemarle Corporation

- 11.2.11.1. Overview

- 11.2.11.2. Products

- 11.2.11.3. SWOT Analysis

- 11.2.11.4. Recent Developments

- 11.2.11.5. Financials (Based on Availability)

- 11.2.1 Clariant

List of Figures

- Figure 1: Global Polypropylene Catalyst Industry Revenue Breakdown (Billion, %) by Region 2025 & 2033

- Figure 2: Global Polypropylene Catalyst Industry Volume Breakdown (K Tons, %) by Region 2025 & 2033

- Figure 3: Asia Pacific Polypropylene Catalyst Industry Revenue (Billion), by Type 2025 & 2033

- Figure 4: Asia Pacific Polypropylene Catalyst Industry Volume (K Tons), by Type 2025 & 2033

- Figure 5: Asia Pacific Polypropylene Catalyst Industry Revenue Share (%), by Type 2025 & 2033

- Figure 6: Asia Pacific Polypropylene Catalyst Industry Volume Share (%), by Type 2025 & 2033

- Figure 7: Asia Pacific Polypropylene Catalyst Industry Revenue (Billion), by Production Process 2025 & 2033

- Figure 8: Asia Pacific Polypropylene Catalyst Industry Volume (K Tons), by Production Process 2025 & 2033

- Figure 9: Asia Pacific Polypropylene Catalyst Industry Revenue Share (%), by Production Process 2025 & 2033

- Figure 10: Asia Pacific Polypropylene Catalyst Industry Volume Share (%), by Production Process 2025 & 2033

- Figure 11: Asia Pacific Polypropylene Catalyst Industry Revenue (Billion), by Application 2025 & 2033

- Figure 12: Asia Pacific Polypropylene Catalyst Industry Volume (K Tons), by Application 2025 & 2033

- Figure 13: Asia Pacific Polypropylene Catalyst Industry Revenue Share (%), by Application 2025 & 2033

- Figure 14: Asia Pacific Polypropylene Catalyst Industry Volume Share (%), by Application 2025 & 2033

- Figure 15: Asia Pacific Polypropylene Catalyst Industry Revenue (Billion), by Country 2025 & 2033

- Figure 16: Asia Pacific Polypropylene Catalyst Industry Volume (K Tons), by Country 2025 & 2033

- Figure 17: Asia Pacific Polypropylene Catalyst Industry Revenue Share (%), by Country 2025 & 2033

- Figure 18: Asia Pacific Polypropylene Catalyst Industry Volume Share (%), by Country 2025 & 2033

- Figure 19: North America Polypropylene Catalyst Industry Revenue (Billion), by Type 2025 & 2033

- Figure 20: North America Polypropylene Catalyst Industry Volume (K Tons), by Type 2025 & 2033

- Figure 21: North America Polypropylene Catalyst Industry Revenue Share (%), by Type 2025 & 2033

- Figure 22: North America Polypropylene Catalyst Industry Volume Share (%), by Type 2025 & 2033

- Figure 23: North America Polypropylene Catalyst Industry Revenue (Billion), by Production Process 2025 & 2033

- Figure 24: North America Polypropylene Catalyst Industry Volume (K Tons), by Production Process 2025 & 2033

- Figure 25: North America Polypropylene Catalyst Industry Revenue Share (%), by Production Process 2025 & 2033

- Figure 26: North America Polypropylene Catalyst Industry Volume Share (%), by Production Process 2025 & 2033

- Figure 27: North America Polypropylene Catalyst Industry Revenue (Billion), by Application 2025 & 2033

- Figure 28: North America Polypropylene Catalyst Industry Volume (K Tons), by Application 2025 & 2033

- Figure 29: North America Polypropylene Catalyst Industry Revenue Share (%), by Application 2025 & 2033

- Figure 30: North America Polypropylene Catalyst Industry Volume Share (%), by Application 2025 & 2033

- Figure 31: North America Polypropylene Catalyst Industry Revenue (Billion), by Country 2025 & 2033

- Figure 32: North America Polypropylene Catalyst Industry Volume (K Tons), by Country 2025 & 2033

- Figure 33: North America Polypropylene Catalyst Industry Revenue Share (%), by Country 2025 & 2033

- Figure 34: North America Polypropylene Catalyst Industry Volume Share (%), by Country 2025 & 2033

- Figure 35: Europe Polypropylene Catalyst Industry Revenue (Billion), by Type 2025 & 2033

- Figure 36: Europe Polypropylene Catalyst Industry Volume (K Tons), by Type 2025 & 2033

- Figure 37: Europe Polypropylene Catalyst Industry Revenue Share (%), by Type 2025 & 2033

- Figure 38: Europe Polypropylene Catalyst Industry Volume Share (%), by Type 2025 & 2033

- Figure 39: Europe Polypropylene Catalyst Industry Revenue (Billion), by Production Process 2025 & 2033

- Figure 40: Europe Polypropylene Catalyst Industry Volume (K Tons), by Production Process 2025 & 2033

- Figure 41: Europe Polypropylene Catalyst Industry Revenue Share (%), by Production Process 2025 & 2033

- Figure 42: Europe Polypropylene Catalyst Industry Volume Share (%), by Production Process 2025 & 2033

- Figure 43: Europe Polypropylene Catalyst Industry Revenue (Billion), by Application 2025 & 2033

- Figure 44: Europe Polypropylene Catalyst Industry Volume (K Tons), by Application 2025 & 2033

- Figure 45: Europe Polypropylene Catalyst Industry Revenue Share (%), by Application 2025 & 2033

- Figure 46: Europe Polypropylene Catalyst Industry Volume Share (%), by Application 2025 & 2033

- Figure 47: Europe Polypropylene Catalyst Industry Revenue (Billion), by Country 2025 & 2033

- Figure 48: Europe Polypropylene Catalyst Industry Volume (K Tons), by Country 2025 & 2033

- Figure 49: Europe Polypropylene Catalyst Industry Revenue Share (%), by Country 2025 & 2033

- Figure 50: Europe Polypropylene Catalyst Industry Volume Share (%), by Country 2025 & 2033

- Figure 51: South America Polypropylene Catalyst Industry Revenue (Billion), by Type 2025 & 2033

- Figure 52: South America Polypropylene Catalyst Industry Volume (K Tons), by Type 2025 & 2033

- Figure 53: South America Polypropylene Catalyst Industry Revenue Share (%), by Type 2025 & 2033

- Figure 54: South America Polypropylene Catalyst Industry Volume Share (%), by Type 2025 & 2033

- Figure 55: South America Polypropylene Catalyst Industry Revenue (Billion), by Production Process 2025 & 2033

- Figure 56: South America Polypropylene Catalyst Industry Volume (K Tons), by Production Process 2025 & 2033

- Figure 57: South America Polypropylene Catalyst Industry Revenue Share (%), by Production Process 2025 & 2033

- Figure 58: South America Polypropylene Catalyst Industry Volume Share (%), by Production Process 2025 & 2033

- Figure 59: South America Polypropylene Catalyst Industry Revenue (Billion), by Application 2025 & 2033

- Figure 60: South America Polypropylene Catalyst Industry Volume (K Tons), by Application 2025 & 2033

- Figure 61: South America Polypropylene Catalyst Industry Revenue Share (%), by Application 2025 & 2033

- Figure 62: South America Polypropylene Catalyst Industry Volume Share (%), by Application 2025 & 2033

- Figure 63: South America Polypropylene Catalyst Industry Revenue (Billion), by Country 2025 & 2033

- Figure 64: South America Polypropylene Catalyst Industry Volume (K Tons), by Country 2025 & 2033

- Figure 65: South America Polypropylene Catalyst Industry Revenue Share (%), by Country 2025 & 2033

- Figure 66: South America Polypropylene Catalyst Industry Volume Share (%), by Country 2025 & 2033

- Figure 67: Middle East and Africa Polypropylene Catalyst Industry Revenue (Billion), by Type 2025 & 2033

- Figure 68: Middle East and Africa Polypropylene Catalyst Industry Volume (K Tons), by Type 2025 & 2033

- Figure 69: Middle East and Africa Polypropylene Catalyst Industry Revenue Share (%), by Type 2025 & 2033

- Figure 70: Middle East and Africa Polypropylene Catalyst Industry Volume Share (%), by Type 2025 & 2033

- Figure 71: Middle East and Africa Polypropylene Catalyst Industry Revenue (Billion), by Production Process 2025 & 2033

- Figure 72: Middle East and Africa Polypropylene Catalyst Industry Volume (K Tons), by Production Process 2025 & 2033

- Figure 73: Middle East and Africa Polypropylene Catalyst Industry Revenue Share (%), by Production Process 2025 & 2033

- Figure 74: Middle East and Africa Polypropylene Catalyst Industry Volume Share (%), by Production Process 2025 & 2033

- Figure 75: Middle East and Africa Polypropylene Catalyst Industry Revenue (Billion), by Application 2025 & 2033

- Figure 76: Middle East and Africa Polypropylene Catalyst Industry Volume (K Tons), by Application 2025 & 2033

- Figure 77: Middle East and Africa Polypropylene Catalyst Industry Revenue Share (%), by Application 2025 & 2033

- Figure 78: Middle East and Africa Polypropylene Catalyst Industry Volume Share (%), by Application 2025 & 2033

- Figure 79: Middle East and Africa Polypropylene Catalyst Industry Revenue (Billion), by Country 2025 & 2033

- Figure 80: Middle East and Africa Polypropylene Catalyst Industry Volume (K Tons), by Country 2025 & 2033

- Figure 81: Middle East and Africa Polypropylene Catalyst Industry Revenue Share (%), by Country 2025 & 2033

- Figure 82: Middle East and Africa Polypropylene Catalyst Industry Volume Share (%), by Country 2025 & 2033

List of Tables

- Table 1: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Type 2020 & 2033

- Table 2: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Type 2020 & 2033

- Table 3: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Production Process 2020 & 2033

- Table 4: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Production Process 2020 & 2033

- Table 5: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Application 2020 & 2033

- Table 6: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Application 2020 & 2033

- Table 7: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Region 2020 & 2033

- Table 8: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Region 2020 & 2033

- Table 9: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Type 2020 & 2033

- Table 10: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Type 2020 & 2033

- Table 11: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Production Process 2020 & 2033

- Table 12: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Production Process 2020 & 2033

- Table 13: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Application 2020 & 2033

- Table 14: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Application 2020 & 2033

- Table 15: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Country 2020 & 2033

- Table 16: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Country 2020 & 2033

- Table 17: China Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 18: China Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 19: India Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 20: India Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 21: Japan Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 22: Japan Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 23: South Korea Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 24: South Korea Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 25: Rest of Asia Pacific Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 26: Rest of Asia Pacific Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 27: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Type 2020 & 2033

- Table 28: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Type 2020 & 2033

- Table 29: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Production Process 2020 & 2033

- Table 30: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Production Process 2020 & 2033

- Table 31: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Application 2020 & 2033

- Table 32: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Application 2020 & 2033

- Table 33: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Country 2020 & 2033

- Table 34: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Country 2020 & 2033

- Table 35: United States Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 36: United States Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 37: Canada Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 38: Canada Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 39: Mexico Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 40: Mexico Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 41: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Type 2020 & 2033

- Table 42: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Type 2020 & 2033

- Table 43: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Production Process 2020 & 2033

- Table 44: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Production Process 2020 & 2033

- Table 45: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Application 2020 & 2033

- Table 46: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Application 2020 & 2033

- Table 47: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Country 2020 & 2033

- Table 48: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Country 2020 & 2033

- Table 49: Germany Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 50: Germany Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 51: United Kingdom Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 52: United Kingdom Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 53: France Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 54: France Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 55: Italy Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 56: Italy Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 57: Rest of Europe Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 58: Rest of Europe Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 59: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Type 2020 & 2033

- Table 60: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Type 2020 & 2033

- Table 61: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Production Process 2020 & 2033

- Table 62: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Production Process 2020 & 2033

- Table 63: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Application 2020 & 2033

- Table 64: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Application 2020 & 2033

- Table 65: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Country 2020 & 2033

- Table 66: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Country 2020 & 2033

- Table 67: Brazil Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 68: Brazil Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 69: Argentina Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 70: Argentina Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 71: Rest of South America Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 72: Rest of South America Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 73: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Type 2020 & 2033

- Table 74: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Type 2020 & 2033

- Table 75: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Production Process 2020 & 2033

- Table 76: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Production Process 2020 & 2033

- Table 77: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Application 2020 & 2033

- Table 78: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Application 2020 & 2033

- Table 79: Global Polypropylene Catalyst Industry Revenue Billion Forecast, by Country 2020 & 2033

- Table 80: Global Polypropylene Catalyst Industry Volume K Tons Forecast, by Country 2020 & 2033

- Table 81: Saudi Arabia Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 82: Saudi Arabia Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 83: South Africa Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 84: South Africa Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 85: Rest of Middle East and Africa Polypropylene Catalyst Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 86: Rest of Middle East and Africa Polypropylene Catalyst Industry Volume (K Tons) Forecast, by Application 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Polypropylene Catalyst Industry?

The projected CAGR is approximately 5.3%.

2. Which companies are prominent players in the Polypropylene Catalyst Industry?

Key companies in the market include Clariant, Sumitomo Chemical Co Ltd, Mitsui Chemicals Inc, China Petrochemical Corporation, W R Grace & Co -Conn, INEOS, Reliance Industries Limited, LyondellBasell Industries Holdings B V, Univation Technologies LLC, TOHO TITANIUM CO LTD, Albemarle Corporation.

3. What are the main segments of the Polypropylene Catalyst Industry?

The market segments include Type, Production Process, Application.

4. Can you provide details about the market size?

The market size is estimated to be USD 1.35 Billion as of 2022.

5. What are some drivers contributing to market growth?

; Growing Demand of Polypropylene Catalyst from Manufacturing of Polypropylene; Other Drivers.

6. What are the notable trends driving market growth?

Growing Demand of Polypropylene Catalyst from Manufacturing of Polypropylene.

7. Are there any restraints impacting market growth?

; Government Regulation on Use of Polypropylene Catalyst; Other Restraints.

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3,950, USD 4,950, and USD 6,950 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Billion and volume, measured in K Tons.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Polypropylene Catalyst Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Polypropylene Catalyst Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Polypropylene Catalyst Industry?

To stay informed about further developments, trends, and reports in the Polypropylene Catalyst Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence