Key Insights

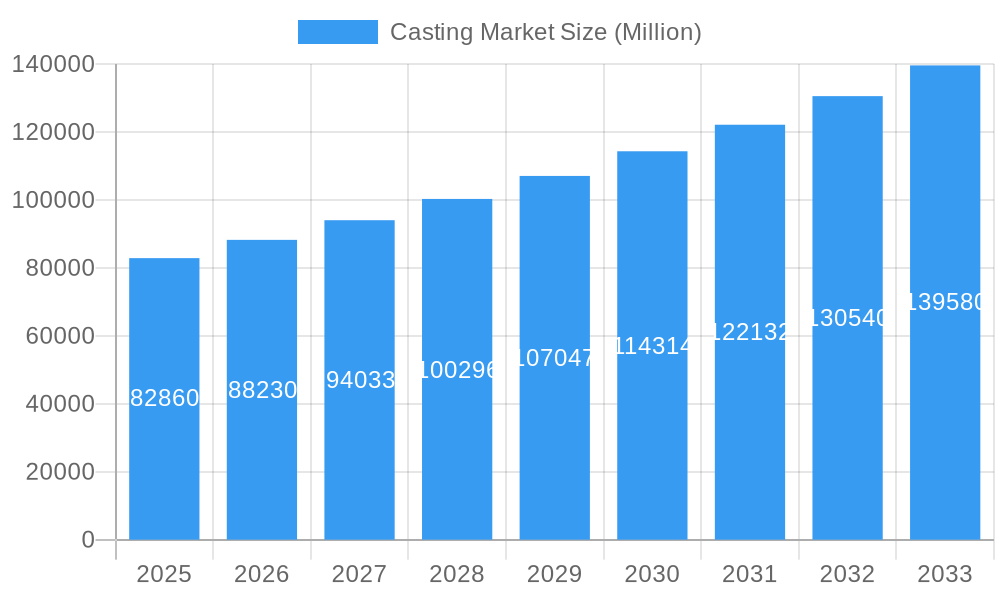

The global die casting market, valued at $82.86 billion in 2025, is projected to experience robust growth, exhibiting a Compound Annual Growth Rate (CAGR) of 6.24% from 2025 to 2033. This expansion is driven by several key factors. The automotive industry's increasing demand for lightweight and high-strength components is a significant catalyst, pushing the adoption of die casting in vehicle manufacturing. Furthermore, the burgeoning electronics sector, with its need for miniaturized and precisely engineered parts, fuels the market's growth. Advancements in die casting processes, such as vacuum and squeeze die casting, improve efficiency and product quality, contributing to wider adoption across various industries including industrial machinery and consumer goods. The prevalent use of aluminum, magnesium, and zinc as raw materials reflects the industry's focus on lightweighting and cost-effectiveness. However, challenges remain, including fluctuating raw material prices and environmental concerns regarding emissions. Addressing these challenges through sustainable practices and process optimization will be crucial for sustained market growth.

Casting Market Market Size (In Billion)

Growth is expected to be particularly strong in the Asia-Pacific region, driven by rapid industrialization and automotive production in countries like China and India. North America and Europe will also contribute significantly, albeit at a slightly slower pace. The market segmentation reveals a dominance of the automotive application, followed by electrical and electronics. Pressure die casting holds the largest process share due to its cost-effectiveness and adaptability. Competitive dynamics are shaped by a mix of established players like Ryobi Die Casting, Georg Fischer, and Alcoa Corporation, alongside emerging regional players. The forecast period anticipates continued market consolidation as companies invest in research and development to enhance their product offerings and expand into new markets, focusing on innovations in materials science and manufacturing processes to address both performance and sustainability requirements.

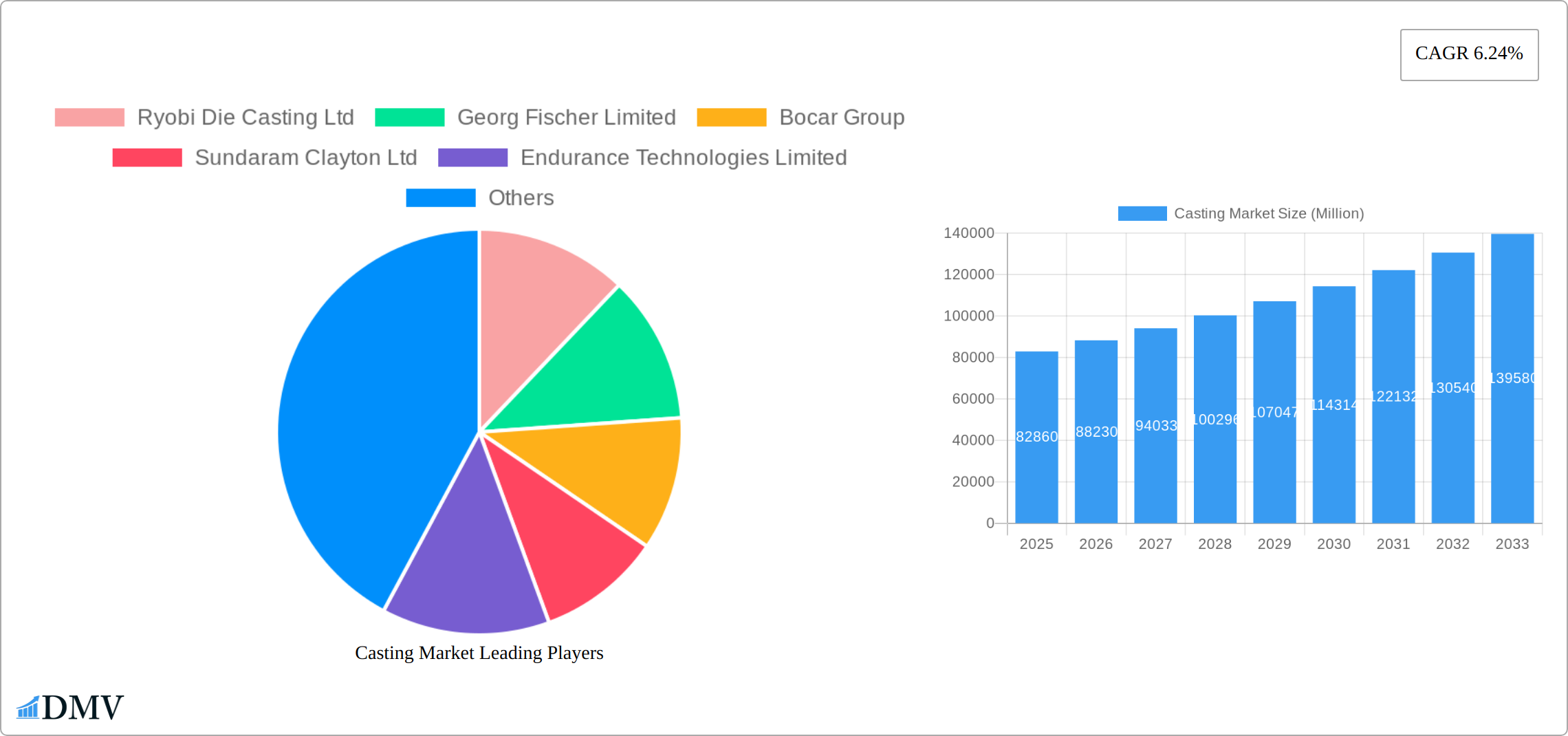

Casting Market Company Market Share

Casting Market Market Composition & Trends

The Casting Market is a dynamic landscape shaped by established industry giants and emerging innovators. Market concentration is notable, with leading companies holding substantial shares. Key players like Ryobi Die Casting Ltd, Georg Fischer Limited, and Bocar Group are prominent examples, collectively controlling approximately 30% of the market. Significant growth drivers include automotive sector advancements, particularly the rising demand for lightweight materials necessitating innovative die casting techniques.

The regulatory environment is evolving, with stricter environmental standards compelling companies to adopt more sustainable casting processes. While alternative technologies such as 3D printing are gaining traction, their current impact on the traditional casting market remains limited due to cost and scalability challenges. Market demand is robust, with the automotive industry leading the way, followed by the electrical and electronics sectors, and a steadily growing industrial applications segment.

Mergers and acquisitions are significantly shaping the market landscape, with deal values exceeding $100 million in the past year. These transactions reflect companies' strategies to expand their technological capabilities, broaden their geographic reach, and consolidate market share. This activity fuels innovation through the integration of new technologies and expertise.

- Market Share Distribution: Top 3 companies hold approximately 30% of the market share.

- M&A Activity: Deal values exceeding $100 million in the last year.

- Primary Market Sectors: Automotive, Electrical & Electronics, and Industrial.

Casting Market Industry Evolution

The Casting Market has undergone significant evolution from 2019 to 2033, marked by robust growth trajectories and technological advancements. During the historical period of 2019-2024, the market witnessed a compound annual growth rate (CAGR) of approximately 4.5%, driven primarily by the automotive sector's demand for lightweight components. This trend is expected to continue into the forecast period of 2025-2033, with a projected CAGR of 5.2%, fueled by the increasing adoption of electric vehicles and the need for efficient, high-performance parts.

Technological advancements have been pivotal, with innovations such as vacuum and squeeze die casting processes improving the quality and efficiency of production. These advancements have led to a 20% increase in the adoption of vacuum die casting in the automotive industry over the last five years. The shift towards aluminum and magnesium as primary raw materials has been notable, with aluminum now accounting for 60% of the raw materials used in casting, up from 50% in 2019.

Consumer demands are shifting towards sustainability and efficiency, prompting manufacturers to invest in research and development to meet these evolving needs. The integration of IoT and automation in casting processes is expected to further enhance productivity and reduce costs, positioning the market for continued growth and innovation.

Leading Regions, Countries, or Segments in Casting Market

The Casting Market exhibits significant regional and segmental variations in dominance. Asia-Pacific leads the way, fueled by a robust automotive industry and strong manufacturing capabilities. Within this region, China stands out as a key player due to its extensive production infrastructure and substantial investments in the automotive and electronics sectors.

Asia-Pacific Market Drivers:

Investment Trends: Significant investments in automotive and electronics manufacturing.

Regulatory Support: Government incentives for electric vehicle (EV) production and sustainable manufacturing initiatives.

Automotive Segment Dominance: The automotive segment is the leading application, accounting for over 45% of the market share. This is driven by the demand for lightweight, high-performance components, especially in electric vehicles. The pressure die casting process is highly favored due to its ability to create complex, high-precision shapes.

Pressure Die Casting Prevalence: Pressure die casting is the dominant process, holding approximately 55% of the market share due to its efficiency and ability to produce high-quality components at scale.

Aluminum's Leading Role as Raw Material: Aluminum is the primary raw material, holding around 60% market share due to its lightweight properties and excellent casting characteristics, making it ideal for automotive and electronics applications.

The dominance of these regions, countries, and segments results from a confluence of factors including technological progress, supportive regulatory frameworks, and strong end-user demand. The integration of advanced casting technologies and a growing focus on sustainability are further bolstering market growth in these key areas.

Casting Market Product Innovations

Innovation in the Casting Market is driven by the need for more efficient and sustainable solutions. Recent advancements include high-pressure die-casting machines capable of producing large, complex components in a single piece, minimizing assembly time and costs. Machines such as the 7,200-ton giant die-casting machine used by Ningbo Tuopu Group Co. Ltd showcase the industry's shift toward integrated manufacturing. The incorporation of new materials like magnesium and advanced alloys further enhances the performance and durability of cast products, meeting the increasing demand for lightweight yet robust components in the automotive and electronics sectors.

Propelling Factors for Casting Market Growth

The Casting Market's growth trajectory is propelled by several key factors: Technological advancements, such as the adoption of vacuum and squeeze die casting, improve production efficiency and product quality. Economic factors include the rising demand for lightweight materials in the automotive industry, influenced by fuel efficiency and emissions regulations. Supportive government policies promoting sustainable manufacturing practices encourage investment in advanced casting technologies. The expansion of electric vehicle production, requiring high-performance lightweight components, significantly boosts the casting market.

Obstacles in the Casting Market Market

The Casting Market faces several obstacles that could impede growth. Regulatory challenges, such as stringent environmental regulations, increase production costs and require significant investments in sustainable technologies. Supply chain disruptions, exacerbated by global events, can delay production and affect market stability. Competitive pressures are intense, with new entrants and substitutes like 3D printing vying for market share. These factors can lead to a 5-10% reduction in market growth potential over the forecast period.

Future Opportunities in Casting Market

Emerging opportunities in the Casting Market include the expansion into new markets, particularly in developing regions with growing industrial sectors. The adoption of advanced technologies like IoT and automation in casting processes presents significant growth potential. Additionally, shifting consumer trends towards sustainability and lightweight materials open new avenues for innovation and market expansion. The focus on electric vehicles and renewable energy components further enhances the market's future prospects.

Major Players in the Casting Market Ecosystem

- Ryobi Die Casting Ltd

- Georg Fischer Limited

- Bocar Group

- Sundaram Clayton Ltd

- Endurance Technologies Limited

- Nemak

- Alcoa Corporation

- Linamar Corporation

- Sandhar Group

- Shiloh Industries

- Koch Enterprises (Gibbs Die Casting Group)

- Meridian Lightweight Technologies UK Ltd

- Rheinmetall AG (Rheinmetall Automotive formerly KSPG AG)

- Form Technologies Inc (Dynacast)

- Rockman Industries

- Engtek Group

Key Developments in Casting Market Industry

- March 2022: Ningbo Tuopu Group Co. Ltd (Tuopu Group) successfully produced an integrated huge die-casting rear cabin using a 7,200-ton giant die-casting machine at its Hangzhou Bay plant. This development significantly enhances production efficiency and reduces assembly costs, particularly impacting the automotive sector.

- March 2021: Sandhar Technologies signed a non-binding Memorandum of Understanding with Unicast Autotech to acquire its aluminum die-casting business. This acquisition strengthens Sandhar's position in the aluminum casting market and expands its product portfolio.

- 2021: Foryou Corporation (Foryou) showcased several die-casted aluminum engine components, new energy drive components, and smart key components at Auto Shanghai 2021, highlighting its innovation in the automotive and electronics sectors.

- March 2021: Rheinmetall AG secured an engine block supply contract worth over EUR 100 Million from a German car manufacturer. Full-scale production is slated to begin in 2023, with the contract extending beyond 2030, ensuring long-term market stability and growth.

Strategic Casting Market Market Forecast

The strategic forecast for the Casting Market from 2025 to 2033 indicates robust growth driven by technological advancements and increasing demand for lightweight materials. The market's potential is further enhanced by the growing adoption of electric vehicles and the need for sustainable manufacturing practices. Opportunities in emerging markets and the integration of IoT and automation in casting processes are expected to propel the market forward, positioning it for significant expansion and innovation in the coming years.

Casting Market Segmentation

-

1. Application

- 1.1. Automotive

- 1.2. Electrical and Electronics

- 1.3. Industrial

- 1.4. Other Applications

-

2. Process

- 2.1. Pressure Die Casting

- 2.2. Vacuum Die Casting

- 2.3. Squeeze Die Casting

- 2.4. Other Processes

-

3. Raw Material

- 3.1. Aluminum

- 3.2. Maginesium

- 3.3. Zinc

Casting Market Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Rest of North America

-

2. Europe

- 2.1. United Kingdom

- 2.2. France

- 2.3. Germany

- 2.4. Italy

- 2.5. Russia

- 2.6. Rest of Europe

-

3. Asia Pacific

- 3.1. China

- 3.2. India

- 3.3. Japan

- 3.4. Australia

- 3.5. Thailand

- 3.6. Malaysia

- 3.7. Indonesia

- 3.8. South Korea

- 3.9. Rest of Asia Pacific

-

4. South America

- 4.1. Brazil

- 4.2. Argentina

- 4.3. Rest of South America

-

5. Middle East and Africa

- 5.1. South Africa

- 5.2. Turkey

- 5.3. Rest of Middle East and Africa

Casting Market Regional Market Share

Geographic Coverage of Casting Market

Casting Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 6.24% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Government Initiatives and the Growing Emphasis on Safety is Driving the Market

- 3.3. Market Restrains

- 3.3.1. Adoption of Steer-By-Wire System Hindering the Market Growth

- 3.4. Market Trends

- 3.4.1. Aluminum Anticipated to Play Key Role in Die Casting Process

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Casting Market Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Application

- 5.1.1. Automotive

- 5.1.2. Electrical and Electronics

- 5.1.3. Industrial

- 5.1.4. Other Applications

- 5.2. Market Analysis, Insights and Forecast - by Process

- 5.2.1. Pressure Die Casting

- 5.2.2. Vacuum Die Casting

- 5.2.3. Squeeze Die Casting

- 5.2.4. Other Processes

- 5.3. Market Analysis, Insights and Forecast - by Raw Material

- 5.3.1. Aluminum

- 5.3.2. Maginesium

- 5.3.3. Zinc

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. North America

- 5.4.2. Europe

- 5.4.3. Asia Pacific

- 5.4.4. South America

- 5.4.5. Middle East and Africa

- 5.1. Market Analysis, Insights and Forecast - by Application

- 6. North America Casting Market Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Application

- 6.1.1. Automotive

- 6.1.2. Electrical and Electronics

- 6.1.3. Industrial

- 6.1.4. Other Applications

- 6.2. Market Analysis, Insights and Forecast - by Process

- 6.2.1. Pressure Die Casting

- 6.2.2. Vacuum Die Casting

- 6.2.3. Squeeze Die Casting

- 6.2.4. Other Processes

- 6.3. Market Analysis, Insights and Forecast - by Raw Material

- 6.3.1. Aluminum

- 6.3.2. Maginesium

- 6.3.3. Zinc

- 6.1. Market Analysis, Insights and Forecast - by Application

- 7. Europe Casting Market Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Application

- 7.1.1. Automotive

- 7.1.2. Electrical and Electronics

- 7.1.3. Industrial

- 7.1.4. Other Applications

- 7.2. Market Analysis, Insights and Forecast - by Process

- 7.2.1. Pressure Die Casting

- 7.2.2. Vacuum Die Casting

- 7.2.3. Squeeze Die Casting

- 7.2.4. Other Processes

- 7.3. Market Analysis, Insights and Forecast - by Raw Material

- 7.3.1. Aluminum

- 7.3.2. Maginesium

- 7.3.3. Zinc

- 7.1. Market Analysis, Insights and Forecast - by Application

- 8. Asia Pacific Casting Market Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Application

- 8.1.1. Automotive

- 8.1.2. Electrical and Electronics

- 8.1.3. Industrial

- 8.1.4. Other Applications

- 8.2. Market Analysis, Insights and Forecast - by Process

- 8.2.1. Pressure Die Casting

- 8.2.2. Vacuum Die Casting

- 8.2.3. Squeeze Die Casting

- 8.2.4. Other Processes

- 8.3. Market Analysis, Insights and Forecast - by Raw Material

- 8.3.1. Aluminum

- 8.3.2. Maginesium

- 8.3.3. Zinc

- 8.1. Market Analysis, Insights and Forecast - by Application

- 9. South America Casting Market Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Application

- 9.1.1. Automotive

- 9.1.2. Electrical and Electronics

- 9.1.3. Industrial

- 9.1.4. Other Applications

- 9.2. Market Analysis, Insights and Forecast - by Process

- 9.2.1. Pressure Die Casting

- 9.2.2. Vacuum Die Casting

- 9.2.3. Squeeze Die Casting

- 9.2.4. Other Processes

- 9.3. Market Analysis, Insights and Forecast - by Raw Material

- 9.3.1. Aluminum

- 9.3.2. Maginesium

- 9.3.3. Zinc

- 9.1. Market Analysis, Insights and Forecast - by Application

- 10. Middle East and Africa Casting Market Analysis, Insights and Forecast, 2020-2032

- 10.1. Market Analysis, Insights and Forecast - by Application

- 10.1.1. Automotive

- 10.1.2. Electrical and Electronics

- 10.1.3. Industrial

- 10.1.4. Other Applications

- 10.2. Market Analysis, Insights and Forecast - by Process

- 10.2.1. Pressure Die Casting

- 10.2.2. Vacuum Die Casting

- 10.2.3. Squeeze Die Casting

- 10.2.4. Other Processes

- 10.3. Market Analysis, Insights and Forecast - by Raw Material

- 10.3.1. Aluminum

- 10.3.2. Maginesium

- 10.3.3. Zinc

- 10.1. Market Analysis, Insights and Forecast - by Application

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2025

- 11.2. Company Profiles

- 11.2.1 Ryobi Die Casting Ltd

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Georg Fischer Limited

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 Bocar Group

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 Sundaram Clayton Ltd

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 Endurance Technologies Limited

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 Nemak

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 Alcoa Corporatio

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 Linamar Corporation

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 Sandhar Group

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 Shiloh Industries

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.11 Koch Enterprises (Gibbs Die Casting Group)

- 11.2.11.1. Overview

- 11.2.11.2. Products

- 11.2.11.3. SWOT Analysis

- 11.2.11.4. Recent Developments

- 11.2.11.5. Financials (Based on Availability)

- 11.2.12 Meridian Lightweight Technologies UK Ltd

- 11.2.12.1. Overview

- 11.2.12.2. Products

- 11.2.12.3. SWOT Analysis

- 11.2.12.4. Recent Developments

- 11.2.12.5. Financials (Based on Availability)

- 11.2.13 Rheinmetall AG (Rheinmetall Automotive formerly KSPG AG)

- 11.2.13.1. Overview

- 11.2.13.2. Products

- 11.2.13.3. SWOT Analysis

- 11.2.13.4. Recent Developments

- 11.2.13.5. Financials (Based on Availability)

- 11.2.14 Form Technologies Inc (Dynacast)

- 11.2.14.1. Overview

- 11.2.14.2. Products

- 11.2.14.3. SWOT Analysis

- 11.2.14.4. Recent Developments

- 11.2.14.5. Financials (Based on Availability)

- 11.2.15 Rockman Industries

- 11.2.15.1. Overview

- 11.2.15.2. Products

- 11.2.15.3. SWOT Analysis

- 11.2.15.4. Recent Developments

- 11.2.15.5. Financials (Based on Availability)

- 11.2.16 Engtek Group

- 11.2.16.1. Overview

- 11.2.16.2. Products

- 11.2.16.3. SWOT Analysis

- 11.2.16.4. Recent Developments

- 11.2.16.5. Financials (Based on Availability)

- 11.2.1 Ryobi Die Casting Ltd

List of Figures

- Figure 1: Global Casting Market Revenue Breakdown (Million, %) by Region 2025 & 2033

- Figure 2: North America Casting Market Revenue (Million), by Application 2025 & 2033

- Figure 3: North America Casting Market Revenue Share (%), by Application 2025 & 2033

- Figure 4: North America Casting Market Revenue (Million), by Process 2025 & 2033

- Figure 5: North America Casting Market Revenue Share (%), by Process 2025 & 2033

- Figure 6: North America Casting Market Revenue (Million), by Raw Material 2025 & 2033

- Figure 7: North America Casting Market Revenue Share (%), by Raw Material 2025 & 2033

- Figure 8: North America Casting Market Revenue (Million), by Country 2025 & 2033

- Figure 9: North America Casting Market Revenue Share (%), by Country 2025 & 2033

- Figure 10: Europe Casting Market Revenue (Million), by Application 2025 & 2033

- Figure 11: Europe Casting Market Revenue Share (%), by Application 2025 & 2033

- Figure 12: Europe Casting Market Revenue (Million), by Process 2025 & 2033

- Figure 13: Europe Casting Market Revenue Share (%), by Process 2025 & 2033

- Figure 14: Europe Casting Market Revenue (Million), by Raw Material 2025 & 2033

- Figure 15: Europe Casting Market Revenue Share (%), by Raw Material 2025 & 2033

- Figure 16: Europe Casting Market Revenue (Million), by Country 2025 & 2033

- Figure 17: Europe Casting Market Revenue Share (%), by Country 2025 & 2033

- Figure 18: Asia Pacific Casting Market Revenue (Million), by Application 2025 & 2033

- Figure 19: Asia Pacific Casting Market Revenue Share (%), by Application 2025 & 2033

- Figure 20: Asia Pacific Casting Market Revenue (Million), by Process 2025 & 2033

- Figure 21: Asia Pacific Casting Market Revenue Share (%), by Process 2025 & 2033

- Figure 22: Asia Pacific Casting Market Revenue (Million), by Raw Material 2025 & 2033

- Figure 23: Asia Pacific Casting Market Revenue Share (%), by Raw Material 2025 & 2033

- Figure 24: Asia Pacific Casting Market Revenue (Million), by Country 2025 & 2033

- Figure 25: Asia Pacific Casting Market Revenue Share (%), by Country 2025 & 2033

- Figure 26: South America Casting Market Revenue (Million), by Application 2025 & 2033

- Figure 27: South America Casting Market Revenue Share (%), by Application 2025 & 2033

- Figure 28: South America Casting Market Revenue (Million), by Process 2025 & 2033

- Figure 29: South America Casting Market Revenue Share (%), by Process 2025 & 2033

- Figure 30: South America Casting Market Revenue (Million), by Raw Material 2025 & 2033

- Figure 31: South America Casting Market Revenue Share (%), by Raw Material 2025 & 2033

- Figure 32: South America Casting Market Revenue (Million), by Country 2025 & 2033

- Figure 33: South America Casting Market Revenue Share (%), by Country 2025 & 2033

- Figure 34: Middle East and Africa Casting Market Revenue (Million), by Application 2025 & 2033

- Figure 35: Middle East and Africa Casting Market Revenue Share (%), by Application 2025 & 2033

- Figure 36: Middle East and Africa Casting Market Revenue (Million), by Process 2025 & 2033

- Figure 37: Middle East and Africa Casting Market Revenue Share (%), by Process 2025 & 2033

- Figure 38: Middle East and Africa Casting Market Revenue (Million), by Raw Material 2025 & 2033

- Figure 39: Middle East and Africa Casting Market Revenue Share (%), by Raw Material 2025 & 2033

- Figure 40: Middle East and Africa Casting Market Revenue (Million), by Country 2025 & 2033

- Figure 41: Middle East and Africa Casting Market Revenue Share (%), by Country 2025 & 2033

List of Tables

- Table 1: Global Casting Market Revenue Million Forecast, by Application 2020 & 2033

- Table 2: Global Casting Market Revenue Million Forecast, by Process 2020 & 2033

- Table 3: Global Casting Market Revenue Million Forecast, by Raw Material 2020 & 2033

- Table 4: Global Casting Market Revenue Million Forecast, by Region 2020 & 2033

- Table 5: Global Casting Market Revenue Million Forecast, by Application 2020 & 2033

- Table 6: Global Casting Market Revenue Million Forecast, by Process 2020 & 2033

- Table 7: Global Casting Market Revenue Million Forecast, by Raw Material 2020 & 2033

- Table 8: Global Casting Market Revenue Million Forecast, by Country 2020 & 2033

- Table 9: United States Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 10: Canada Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 11: Rest of North America Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 12: Global Casting Market Revenue Million Forecast, by Application 2020 & 2033

- Table 13: Global Casting Market Revenue Million Forecast, by Process 2020 & 2033

- Table 14: Global Casting Market Revenue Million Forecast, by Raw Material 2020 & 2033

- Table 15: Global Casting Market Revenue Million Forecast, by Country 2020 & 2033

- Table 16: United Kingdom Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 17: France Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 18: Germany Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 19: Italy Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 20: Russia Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 21: Rest of Europe Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 22: Global Casting Market Revenue Million Forecast, by Application 2020 & 2033

- Table 23: Global Casting Market Revenue Million Forecast, by Process 2020 & 2033

- Table 24: Global Casting Market Revenue Million Forecast, by Raw Material 2020 & 2033

- Table 25: Global Casting Market Revenue Million Forecast, by Country 2020 & 2033

- Table 26: China Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 27: India Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 28: Japan Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 29: Australia Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 30: Thailand Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 31: Malaysia Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 32: Indonesia Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 33: South Korea Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 34: Rest of Asia Pacific Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 35: Global Casting Market Revenue Million Forecast, by Application 2020 & 2033

- Table 36: Global Casting Market Revenue Million Forecast, by Process 2020 & 2033

- Table 37: Global Casting Market Revenue Million Forecast, by Raw Material 2020 & 2033

- Table 38: Global Casting Market Revenue Million Forecast, by Country 2020 & 2033

- Table 39: Brazil Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 40: Argentina Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 41: Rest of South America Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 42: Global Casting Market Revenue Million Forecast, by Application 2020 & 2033

- Table 43: Global Casting Market Revenue Million Forecast, by Process 2020 & 2033

- Table 44: Global Casting Market Revenue Million Forecast, by Raw Material 2020 & 2033

- Table 45: Global Casting Market Revenue Million Forecast, by Country 2020 & 2033

- Table 46: South Africa Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 47: Turkey Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 48: Rest of Middle East and Africa Casting Market Revenue (Million) Forecast, by Application 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Casting Market?

The projected CAGR is approximately 6.24%.

2. Which companies are prominent players in the Casting Market?

Key companies in the market include Ryobi Die Casting Ltd, Georg Fischer Limited, Bocar Group, Sundaram Clayton Ltd, Endurance Technologies Limited, Nemak, Alcoa Corporatio, Linamar Corporation, Sandhar Group, Shiloh Industries, Koch Enterprises (Gibbs Die Casting Group), Meridian Lightweight Technologies UK Ltd, Rheinmetall AG (Rheinmetall Automotive formerly KSPG AG), Form Technologies Inc (Dynacast), Rockman Industries, Engtek Group.

3. What are the main segments of the Casting Market?

The market segments include Application, Process, Raw Material.

4. Can you provide details about the market size?

The market size is estimated to be USD 82.86 Million as of 2022.

5. What are some drivers contributing to market growth?

Government Initiatives and the Growing Emphasis on Safety is Driving the Market.

6. What are the notable trends driving market growth?

Aluminum Anticipated to Play Key Role in Die Casting Process.

7. Are there any restraints impacting market growth?

Adoption of Steer-By-Wire System Hindering the Market Growth.

8. Can you provide examples of recent developments in the market?

In March 2022, Ningbo Tuopu Group Co. Ltd (Tuopu Group) announced that the integrated huge die-casting rear cabin that is developed based on the 7,200-ton giant die-casting machine rolled off the assembly line at the Hangzhou Bay plant in Ningbo.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Casting Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Casting Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Casting Market?

To stay informed about further developments, trends, and reports in the Casting Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence