Key Insights

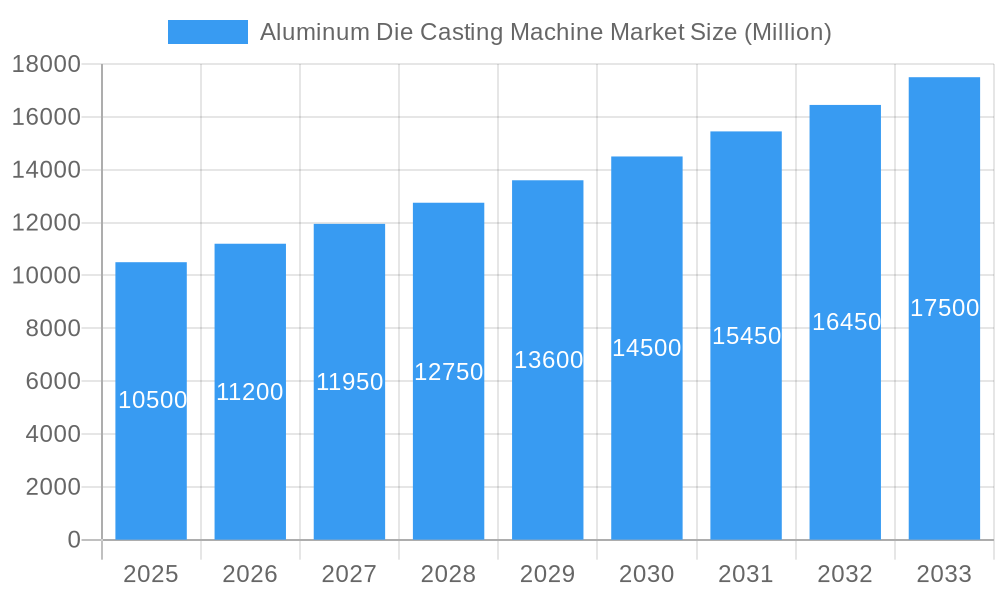

The global Aluminum Die Casting Machine Market is poised for robust growth, with an estimated market size of approximately USD 10,500 million in 2025, projecting a Compound Annual Growth Rate (CAGR) exceeding 6.00% through 2033. This expansion is primarily propelled by the escalating demand from the automotive sector, which relies heavily on lightweight and durable aluminum components for fuel efficiency and performance enhancement. The burgeoning 3C (Computer, Communication, Consumer Electronics) industry also significantly contributes to market momentum, driven by the increasing production of sophisticated electronic devices requiring precision-engineered metal casings. Emerging economies, particularly in the Asia Pacific region, are emerging as key growth engines due to rapid industrialization and a burgeoning manufacturing base.

Aluminum Die Casting Machine Market Market Size (In Billion)

The market's dynamism is further shaped by ongoing technological advancements in die casting machinery, focusing on enhanced precision, speed, and energy efficiency. Innovations in both cold chamber and hot chamber die casting machines cater to diverse application needs, from intricate electronic parts to large automotive components. While the increasing adoption of advanced manufacturing techniques and the growing preference for sustainable production methods are strong drivers, the market faces certain restraints. These include the high initial investment cost for sophisticated die casting equipment and the potential for fluctuating raw material prices. Despite these challenges, the continuous push for lightweighting across various industries, coupled with the inherent recyclability of aluminum, positions the market for sustained and significant expansion in the coming years.

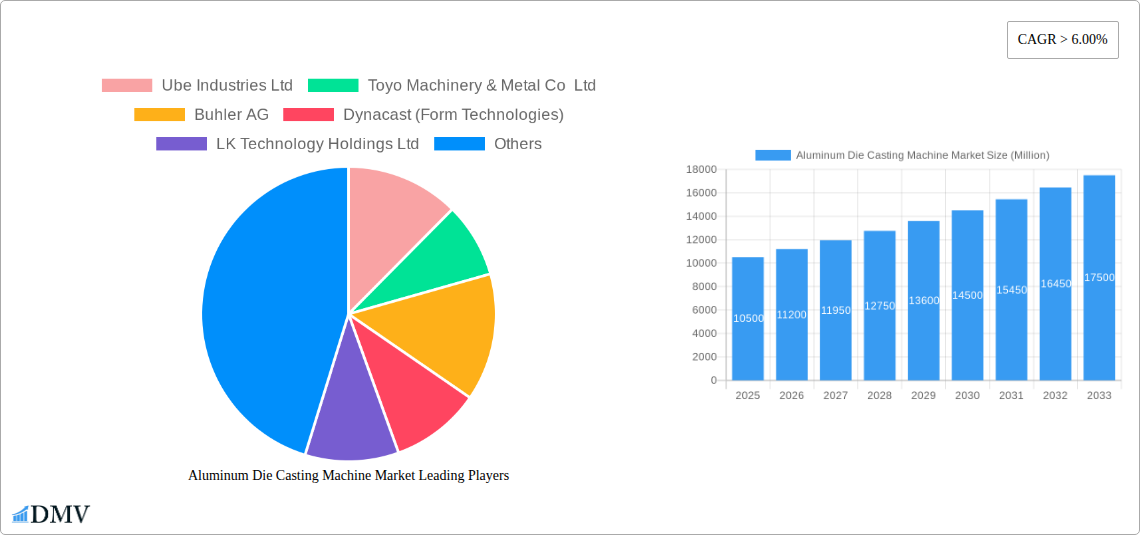

Aluminum Die Casting Machine Market Company Market Share

Unveiling the Aluminum Die Casting Machine Market: A Comprehensive Analysis for Stakeholders

This in-depth report offers an unparalleled view into the global Aluminum Die Casting Machine Market, a critical sector powering advancements across automotive, 3C industry, and beyond. Forecasted to reach an estimated XXX Million by 2025, this study meticulously examines market dynamics from 2019 to 2033, with a comprehensive historical analysis (2019-2024) and a robust forecast (2025-2033) based on the 2025 base year. Delve into the intricate interplay of machine types (Cold Chamber Die Casting Machines, Hot Chamber Die Casting Machines), raw materials (Aluminum, Magnesium, Other Raw Materials), and burgeoning industry trends. Discover the strategic moves of leading players like Ube Industries Ltd, Toyo Machinery & Metal Co Ltd, and Buhler AG, and understand the technological innovations and market evolution shaping this vital industry.

Aluminum Die Casting Machine Market Market Composition & Trends

The Aluminum Die Casting Machine Market is characterized by a moderate level of concentration, with several key players holding significant market shares. Innovation catalysts are primarily driven by the increasing demand for lightweight components in the automotive sector and the miniaturization trends in the 3C industry. Regulatory landscapes, while varying by region, generally favor environmental sustainability and safety standards in manufacturing processes. Substitute products, such as stamping and forging, exist but often fall short in terms of complex geometries and production speed offered by die casting. End-user profiles range from large automotive manufacturers and their Tier-1 suppliers to consumer electronics giants and specialized industrial component producers. Mergers and acquisition (M&A) activities are pivotal for market expansion and technological integration, with recent deal values estimated in the hundreds of millions.

- Market Share Distribution: Leading manufacturers collectively account for approximately 60-70% of the global market share.

- M&A Deal Values: Significant M&A activities in the past three years are estimated to be in the range of XXX to XXX Million.

- Innovation Catalysts:

- Growing demand for lightweight materials in electric vehicles (EVs).

- Advancements in automation and Industry 4.0 integration.

- Development of high-performance aluminum alloys.

- End-User Industries:

- Automotive (approx. 50% of market share).

- 3C Industry (approx. 25% of market share).

- Other Industries (including aerospace, medical, and industrial machinery).

Aluminum Die Casting Machine Market Industry Evolution

The Aluminum Die Casting Machine Market has witnessed a dynamic evolution driven by relentless technological advancements and the ever-shifting demands of its core end-user industries. Over the historical period (2019-2024), the market experienced steady growth, underpinned by the increasing adoption of aluminum alloys for their superior strength-to-weight ratio and corrosion resistance. The automotive sector, in particular, has been a primary growth engine, propelled by stringent fuel efficiency regulations and the burgeoning demand for electric vehicles, which heavily rely on lightweight components for optimal performance and range. The 3C industry has also contributed significantly, with die casting machines enabling the intricate and precise manufacturing of housings and internal components for smartphones, laptops, and other electronic devices.

Technological advancements have played a crucial role in this evolution. The development of high-pressure die casting (HPDC) machines with enhanced precision, faster cycle times, and improved energy efficiency has been a key trend. Furthermore, the integration of automation, robotics, and Industry 4.0 principles has revolutionized production processes, leading to increased productivity, reduced labor costs, and enhanced quality control. The introduction of advanced simulation software has also allowed manufacturers to optimize mold design and process parameters, minimizing defects and scrap rates.

Consumer demand has also shaped the industry's trajectory. The global push towards sustainability and environmental consciousness has fueled the demand for lightweight vehicles and energy-efficient electronics, both of which benefit immensely from the capabilities of aluminum die casting. The ability to produce complex shapes with thin walls and tight tolerances, coupled with the recyclability of aluminum, makes it an attractive material choice. Consequently, the market has seen a growing preference for machines capable of handling larger casting sizes, such as integrated body structural components for vehicles, and those that can achieve higher levels of automation and smart manufacturing capabilities. The forecast period (2025-2033) is expected to witness accelerated growth, driven by these ongoing trends and emerging innovations in alloy development and machine technology, with an estimated compound annual growth rate (CAGR) of XX%.

Leading Regions, Countries, or Segments in Aluminum Die Casting Machine Market

The Aluminum Die Casting Machine Market exhibits distinct leadership across various segments, with the Automotive Industry emerging as the dominant end-user sector globally. This dominance is fueled by the continuous drive for vehicle lightweighting to enhance fuel efficiency and reduce emissions, a trend further amplified by the rapid expansion of the electric vehicle (EV) market. Countries like China, Germany, the United States, and Japan are at the forefront of this demand, owing to their robust automotive manufacturing bases and progressive regulatory frameworks encouraging sustainable mobility solutions.

Within machine types, Cold Chamber Die Casting Machines hold a substantial market share, primarily due to their versatility in casting a wide range of aluminum alloys and their suitability for larger and more complex parts, which are increasingly required in automotive structural components and large electronic device housings. The raw material segment is overwhelmingly dominated by Aluminum, given its inherent properties of low density, high strength-to-weight ratio, and excellent recyclability, making it the material of choice for die casting applications.

- Dominant Industry Segment:

- Automotive: This segment is the primary driver of the Aluminum Die Casting Machine Market, accounting for an estimated 50% of the global market revenue.

- Key Drivers:

- Increasing demand for lightweight vehicle components for fuel efficiency.

- Rapid growth of the electric vehicle (EV) market requiring lighter chassis and battery enclosures.

- Strict government regulations on emissions and fuel economy.

- Trend towards integrated body structural parts, reducing assembly complexity and weight.

- Key Drivers:

- Automotive: This segment is the primary driver of the Aluminum Die Casting Machine Market, accounting for an estimated 50% of the global market revenue.

- Leading Machine Type:

- Cold Chamber Die Casting Machines: These machines are favored for their ability to cast high-melting-point alloys like aluminum and are essential for producing larger, more intricate automotive parts.

- Key Drivers:

- Suitability for a wide range of aluminum alloys.

- Capability to produce large and complex castings.

- Advancements in automation and process control for higher precision.

- Key Drivers:

- Cold Chamber Die Casting Machines: These machines are favored for their ability to cast high-melting-point alloys like aluminum and are essential for producing larger, more intricate automotive parts.

- Dominant Raw Material:

- Aluminum: The widespread availability, favorable physical properties, and recyclability of aluminum make it the undisputed leader in this market.

- Key Drivers:

- Excellent strength-to-weight ratio.

- Corrosion resistance.

- High recyclability, aligning with sustainability goals.

- Cost-effectiveness compared to other high-performance metals.

- Key Drivers:

- Aluminum: The widespread availability, favorable physical properties, and recyclability of aluminum make it the undisputed leader in this market.

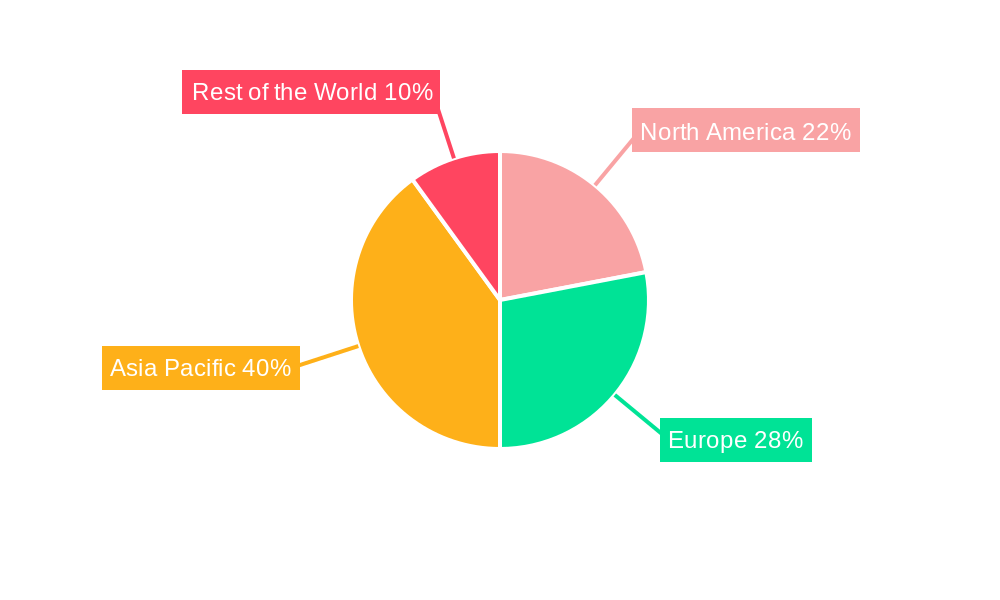

- Leading Regions:

- Asia-Pacific: Dominated by China, this region leads in both production and consumption of aluminum die casting machines, driven by its massive automotive and electronics manufacturing sectors.

- Europe: Germany is a key player, driven by its strong automotive industry and focus on high-quality precision casting.

- North America: The United States shows significant demand, particularly from the automotive and aerospace sectors.

Aluminum Die Casting Machine Market Product Innovations

Recent product innovations in the Aluminum Die Casting Machine Market are centered on enhancing efficiency, precision, and sustainability. Manufacturers are increasingly integrating advanced automation and Industry 4.0 technologies, such as AI-powered process monitoring and predictive maintenance systems, to optimize casting quality and minimize downtime. The development of high-speed, high-precision machines capable of producing thinner walls and more complex geometries is crucial for meeting the evolving demands of the automotive and 3C industries. Furthermore, there is a growing emphasis on energy-efficient designs and machines that can utilize recycled aluminum alloys with minimal compromise on performance.

Propelling Factors for Aluminum Die Casting Machine Market Growth

The Aluminum Die Casting Machine Market is propelled by a confluence of technological, economic, and regulatory factors. The relentless pursuit of lightweighting in the automotive sector, particularly for electric vehicles, is a primary growth driver, as aluminum offers a superior strength-to-weight ratio compared to traditional materials. Economic recovery and increased manufacturing output across various industries, including consumer electronics and industrial machinery, also contribute to higher demand. Stringent environmental regulations worldwide are indirectly boosting the market by incentivizing the use of more sustainable materials like aluminum and the adoption of energy-efficient manufacturing processes. The increasing sophistication of die casting technology, enabling the production of more complex and precise components, further fuels market expansion.

Obstacles in the Aluminum Die Casting Machine Market Market

Despite its robust growth trajectory, the Aluminum Die Casting Machine Market faces several obstacles. The high initial capital investment required for advanced die casting machinery can be a significant barrier, particularly for small and medium-sized enterprises (SMEs). Fluctuations in raw material prices, specifically aluminum, can impact manufacturing costs and profit margins. Intense competition among global manufacturers also leads to price pressures. Furthermore, the increasing complexity of die cast components necessitates highly skilled labor for operation and maintenance, leading to potential workforce shortages. Evolving environmental regulations, while a driver for innovation, can also pose compliance challenges and necessitate costly upgrades to existing machinery.

Future Opportunities in Aluminum Die Casting Machine Market

The future of the Aluminum Die Casting Machine Market is ripe with opportunities, driven by emerging trends and expanding applications. The burgeoning demand for electric vehicles, with their extensive use of lightweight aluminum components, presents a significant growth avenue. The expansion of the 5G infrastructure and the increasing demand for advanced electronic devices will continue to fuel the need for precision die casting of complex components. Innovations in additive manufacturing integrated with die casting processes could open new possibilities for complex part geometries and rapid prototyping. Furthermore, the growing emphasis on circular economy principles and the recyclability of aluminum alloys present opportunities for manufacturers to develop machines optimized for processing secondary aluminum, aligning with sustainability goals.

Major Players in the Aluminum Die Casting Machine Market Ecosystem

- Ube Industries Ltd

- Toyo Machinery & Metal Co Ltd

- Buhler AG

- Dynacast (Form Technologies)

- LK Technology Holdings Ltd

- Italpresse Gauss

- Toshiba Machine Co Ltd

- Oskar Frech GmbH + Co KG

- IDRA Group

- Zitai Precision Machinery Co Lt

Key Developments in Aluminum Die Casting Machine Market Industry

- May 2022: GF Casting Solutions and Bocar Group signed an agreement to offer specialized high-pressure die casting products and services worldwide, aiming to enhance customer value through combined capabilities.

- January 2022: Jingcheng Gongke Automotive Systems Co., Ltd. Die-casting Branch and LK Group held a forum discussing integrated die casting technology, new materials, and lightweight design for the automobile manufacturing industry, forging strategic cooperation.

- December 2021: Nissei ASB Machine Co. Ltd. and Shibaura Machine Co. Ltd. entered a memorandum of understanding to form a partnership focused on emerging markets in the injection molding and extruder sectors.

- February 2021: Nantong Jiangzhong Photoelectricity Co. Ltd installed an Italpresse Gauss TF5700 high pressure die casting (HPDC) machine and a Westomat 3100 from StrikoWestofen at its facility in Jiangsu province, China.

- September 2021: Hanon Systems announced the inauguration of two sites in Hungary: a new production facility in Pécs and an expansion in Rétság, with the new plant in Pécs featuring modern machinery for horizontal die casting to increase production capacity for fluid transport products.

Strategic Aluminum Die Casting Machine Market Market Forecast

The strategic forecast for the Aluminum Die Casting Machine Market indicates sustained and robust growth in the coming years. Key growth catalysts include the escalating global demand for lightweight vehicles, driven by stricter environmental regulations and the proliferation of electric mobility solutions. The continuous innovation in the 3C industry, demanding increasingly complex and miniaturized components, will further stimulate the market. Investments in advanced manufacturing technologies, such as automation and Industry 4.0 integration, are expected to drive efficiency and productivity gains, making die casting a more attractive manufacturing process. The growing focus on sustainability and the recyclability of aluminum alloys also positions the market for long-term expansion, as industries increasingly adopt environmentally conscious practices. The market is projected to reach XXX Million by 2033, with a significant CAGR of XX% during the forecast period.

Aluminum Die Casting Machine Market Segmentation

-

1. Machine Type

- 1.1. Cold Chamber Die Casting Machines

- 1.2. Hot Chamber Die Casting Machines

-

2. Industry

- 2.1. Automotive

- 2.2. 3C Industry

- 2.3. Other Industries

-

3. Raw Material

- 3.1. Aluminum

- 3.2. Magnesium

- 3.3. Other Raw Materials

Aluminum Die Casting Machine Market Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Rest of North America

-

2. Europe

- 2.1. Germany

- 2.2. United Kingdom

- 2.3. France

- 2.4. Italy

- 2.5. Rest of Europe

-

3. Asia Pacific

- 3.1. China

- 3.2. India

- 3.3. South Korea

- 3.4. Japan

- 3.5. Rest of Asia Pacific

-

4. Rest of the World

- 4.1. South America

- 4.2. Middle East and Africa

Aluminum Die Casting Machine Market Regional Market Share

Geographic Coverage of Aluminum Die Casting Machine Market

Aluminum Die Casting Machine Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of > 6.00% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Rising Recreational and Motorsports Activities is Expected to Drive the Market; Others

- 3.3. Market Restrains

- 3.3.1. High Value and Maintenance Cost Offered to Restrain the Market Growth; Others

- 3.4. Market Trends

- 3.4.1. Growing Adoption of Aluminum in Die Casting Machinery to Enhance Demand in the Market

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Aluminum Die Casting Machine Market Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Machine Type

- 5.1.1. Cold Chamber Die Casting Machines

- 5.1.2. Hot Chamber Die Casting Machines

- 5.2. Market Analysis, Insights and Forecast - by Industry

- 5.2.1. Automotive

- 5.2.2. 3C Industry

- 5.2.3. Other Industries

- 5.3. Market Analysis, Insights and Forecast - by Raw Material

- 5.3.1. Aluminum

- 5.3.2. Magnesium

- 5.3.3. Other Raw Materials

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. North America

- 5.4.2. Europe

- 5.4.3. Asia Pacific

- 5.4.4. Rest of the World

- 5.1. Market Analysis, Insights and Forecast - by Machine Type

- 6. North America Aluminum Die Casting Machine Market Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Machine Type

- 6.1.1. Cold Chamber Die Casting Machines

- 6.1.2. Hot Chamber Die Casting Machines

- 6.2. Market Analysis, Insights and Forecast - by Industry

- 6.2.1. Automotive

- 6.2.2. 3C Industry

- 6.2.3. Other Industries

- 6.3. Market Analysis, Insights and Forecast - by Raw Material

- 6.3.1. Aluminum

- 6.3.2. Magnesium

- 6.3.3. Other Raw Materials

- 6.1. Market Analysis, Insights and Forecast - by Machine Type

- 7. Europe Aluminum Die Casting Machine Market Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Machine Type

- 7.1.1. Cold Chamber Die Casting Machines

- 7.1.2. Hot Chamber Die Casting Machines

- 7.2. Market Analysis, Insights and Forecast - by Industry

- 7.2.1. Automotive

- 7.2.2. 3C Industry

- 7.2.3. Other Industries

- 7.3. Market Analysis, Insights and Forecast - by Raw Material

- 7.3.1. Aluminum

- 7.3.2. Magnesium

- 7.3.3. Other Raw Materials

- 7.1. Market Analysis, Insights and Forecast - by Machine Type

- 8. Asia Pacific Aluminum Die Casting Machine Market Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Machine Type

- 8.1.1. Cold Chamber Die Casting Machines

- 8.1.2. Hot Chamber Die Casting Machines

- 8.2. Market Analysis, Insights and Forecast - by Industry

- 8.2.1. Automotive

- 8.2.2. 3C Industry

- 8.2.3. Other Industries

- 8.3. Market Analysis, Insights and Forecast - by Raw Material

- 8.3.1. Aluminum

- 8.3.2. Magnesium

- 8.3.3. Other Raw Materials

- 8.1. Market Analysis, Insights and Forecast - by Machine Type

- 9. Rest of the World Aluminum Die Casting Machine Market Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Machine Type

- 9.1.1. Cold Chamber Die Casting Machines

- 9.1.2. Hot Chamber Die Casting Machines

- 9.2. Market Analysis, Insights and Forecast - by Industry

- 9.2.1. Automotive

- 9.2.2. 3C Industry

- 9.2.3. Other Industries

- 9.3. Market Analysis, Insights and Forecast - by Raw Material

- 9.3.1. Aluminum

- 9.3.2. Magnesium

- 9.3.3. Other Raw Materials

- 9.1. Market Analysis, Insights and Forecast - by Machine Type

- 10. Competitive Analysis

- 10.1. Global Market Share Analysis 2025

- 10.2. Company Profiles

- 10.2.1 Ube Industries Ltd

- 10.2.1.1. Overview

- 10.2.1.2. Products

- 10.2.1.3. SWOT Analysis

- 10.2.1.4. Recent Developments

- 10.2.1.5. Financials (Based on Availability)

- 10.2.2 Toyo Machinery & Metal Co Ltd

- 10.2.2.1. Overview

- 10.2.2.2. Products

- 10.2.2.3. SWOT Analysis

- 10.2.2.4. Recent Developments

- 10.2.2.5. Financials (Based on Availability)

- 10.2.3 Buhler AG

- 10.2.3.1. Overview

- 10.2.3.2. Products

- 10.2.3.3. SWOT Analysis

- 10.2.3.4. Recent Developments

- 10.2.3.5. Financials (Based on Availability)

- 10.2.4 Dynacast (Form Technologies)

- 10.2.4.1. Overview

- 10.2.4.2. Products

- 10.2.4.3. SWOT Analysis

- 10.2.4.4. Recent Developments

- 10.2.4.5. Financials (Based on Availability)

- 10.2.5 LK Technology Holdings Ltd

- 10.2.5.1. Overview

- 10.2.5.2. Products

- 10.2.5.3. SWOT Analysis

- 10.2.5.4. Recent Developments

- 10.2.5.5. Financials (Based on Availability)

- 10.2.6 Italpresse Gauss

- 10.2.6.1. Overview

- 10.2.6.2. Products

- 10.2.6.3. SWOT Analysis

- 10.2.6.4. Recent Developments

- 10.2.6.5. Financials (Based on Availability)

- 10.2.7 Toshiba Machine Co Ltd

- 10.2.7.1. Overview

- 10.2.7.2. Products

- 10.2.7.3. SWOT Analysis

- 10.2.7.4. Recent Developments

- 10.2.7.5. Financials (Based on Availability)

- 10.2.8 Oskar Frech GmbH + Co KG

- 10.2.8.1. Overview

- 10.2.8.2. Products

- 10.2.8.3. SWOT Analysis

- 10.2.8.4. Recent Developments

- 10.2.8.5. Financials (Based on Availability)

- 10.2.9 IDRA Group

- 10.2.9.1. Overview

- 10.2.9.2. Products

- 10.2.9.3. SWOT Analysis

- 10.2.9.4. Recent Developments

- 10.2.9.5. Financials (Based on Availability)

- 10.2.10 Zitai Precision Machinery Co Lt

- 10.2.10.1. Overview

- 10.2.10.2. Products

- 10.2.10.3. SWOT Analysis

- 10.2.10.4. Recent Developments

- 10.2.10.5. Financials (Based on Availability)

- 10.2.1 Ube Industries Ltd

List of Figures

- Figure 1: Global Aluminum Die Casting Machine Market Revenue Breakdown (Million, %) by Region 2025 & 2033

- Figure 2: North America Aluminum Die Casting Machine Market Revenue (Million), by Machine Type 2025 & 2033

- Figure 3: North America Aluminum Die Casting Machine Market Revenue Share (%), by Machine Type 2025 & 2033

- Figure 4: North America Aluminum Die Casting Machine Market Revenue (Million), by Industry 2025 & 2033

- Figure 5: North America Aluminum Die Casting Machine Market Revenue Share (%), by Industry 2025 & 2033

- Figure 6: North America Aluminum Die Casting Machine Market Revenue (Million), by Raw Material 2025 & 2033

- Figure 7: North America Aluminum Die Casting Machine Market Revenue Share (%), by Raw Material 2025 & 2033

- Figure 8: North America Aluminum Die Casting Machine Market Revenue (Million), by Country 2025 & 2033

- Figure 9: North America Aluminum Die Casting Machine Market Revenue Share (%), by Country 2025 & 2033

- Figure 10: Europe Aluminum Die Casting Machine Market Revenue (Million), by Machine Type 2025 & 2033

- Figure 11: Europe Aluminum Die Casting Machine Market Revenue Share (%), by Machine Type 2025 & 2033

- Figure 12: Europe Aluminum Die Casting Machine Market Revenue (Million), by Industry 2025 & 2033

- Figure 13: Europe Aluminum Die Casting Machine Market Revenue Share (%), by Industry 2025 & 2033

- Figure 14: Europe Aluminum Die Casting Machine Market Revenue (Million), by Raw Material 2025 & 2033

- Figure 15: Europe Aluminum Die Casting Machine Market Revenue Share (%), by Raw Material 2025 & 2033

- Figure 16: Europe Aluminum Die Casting Machine Market Revenue (Million), by Country 2025 & 2033

- Figure 17: Europe Aluminum Die Casting Machine Market Revenue Share (%), by Country 2025 & 2033

- Figure 18: Asia Pacific Aluminum Die Casting Machine Market Revenue (Million), by Machine Type 2025 & 2033

- Figure 19: Asia Pacific Aluminum Die Casting Machine Market Revenue Share (%), by Machine Type 2025 & 2033

- Figure 20: Asia Pacific Aluminum Die Casting Machine Market Revenue (Million), by Industry 2025 & 2033

- Figure 21: Asia Pacific Aluminum Die Casting Machine Market Revenue Share (%), by Industry 2025 & 2033

- Figure 22: Asia Pacific Aluminum Die Casting Machine Market Revenue (Million), by Raw Material 2025 & 2033

- Figure 23: Asia Pacific Aluminum Die Casting Machine Market Revenue Share (%), by Raw Material 2025 & 2033

- Figure 24: Asia Pacific Aluminum Die Casting Machine Market Revenue (Million), by Country 2025 & 2033

- Figure 25: Asia Pacific Aluminum Die Casting Machine Market Revenue Share (%), by Country 2025 & 2033

- Figure 26: Rest of the World Aluminum Die Casting Machine Market Revenue (Million), by Machine Type 2025 & 2033

- Figure 27: Rest of the World Aluminum Die Casting Machine Market Revenue Share (%), by Machine Type 2025 & 2033

- Figure 28: Rest of the World Aluminum Die Casting Machine Market Revenue (Million), by Industry 2025 & 2033

- Figure 29: Rest of the World Aluminum Die Casting Machine Market Revenue Share (%), by Industry 2025 & 2033

- Figure 30: Rest of the World Aluminum Die Casting Machine Market Revenue (Million), by Raw Material 2025 & 2033

- Figure 31: Rest of the World Aluminum Die Casting Machine Market Revenue Share (%), by Raw Material 2025 & 2033

- Figure 32: Rest of the World Aluminum Die Casting Machine Market Revenue (Million), by Country 2025 & 2033

- Figure 33: Rest of the World Aluminum Die Casting Machine Market Revenue Share (%), by Country 2025 & 2033

List of Tables

- Table 1: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Machine Type 2020 & 2033

- Table 2: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Industry 2020 & 2033

- Table 3: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Raw Material 2020 & 2033

- Table 4: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Region 2020 & 2033

- Table 5: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Machine Type 2020 & 2033

- Table 6: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Industry 2020 & 2033

- Table 7: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Raw Material 2020 & 2033

- Table 8: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Country 2020 & 2033

- Table 9: United States Aluminum Die Casting Machine Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 10: Canada Aluminum Die Casting Machine Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 11: Rest of North America Aluminum Die Casting Machine Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 12: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Machine Type 2020 & 2033

- Table 13: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Industry 2020 & 2033

- Table 14: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Raw Material 2020 & 2033

- Table 15: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Country 2020 & 2033

- Table 16: Germany Aluminum Die Casting Machine Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 17: United Kingdom Aluminum Die Casting Machine Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 18: France Aluminum Die Casting Machine Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 19: Italy Aluminum Die Casting Machine Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 20: Rest of Europe Aluminum Die Casting Machine Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 21: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Machine Type 2020 & 2033

- Table 22: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Industry 2020 & 2033

- Table 23: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Raw Material 2020 & 2033

- Table 24: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Country 2020 & 2033

- Table 25: China Aluminum Die Casting Machine Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 26: India Aluminum Die Casting Machine Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 27: South Korea Aluminum Die Casting Machine Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 28: Japan Aluminum Die Casting Machine Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 29: Rest of Asia Pacific Aluminum Die Casting Machine Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 30: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Machine Type 2020 & 2033

- Table 31: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Industry 2020 & 2033

- Table 32: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Raw Material 2020 & 2033

- Table 33: Global Aluminum Die Casting Machine Market Revenue Million Forecast, by Country 2020 & 2033

- Table 34: South America Aluminum Die Casting Machine Market Revenue (Million) Forecast, by Application 2020 & 2033

- Table 35: Middle East and Africa Aluminum Die Casting Machine Market Revenue (Million) Forecast, by Application 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Aluminum Die Casting Machine Market?

The projected CAGR is approximately > 6.00%.

2. Which companies are prominent players in the Aluminum Die Casting Machine Market?

Key companies in the market include Ube Industries Ltd, Toyo Machinery & Metal Co Ltd, Buhler AG, Dynacast (Form Technologies), LK Technology Holdings Ltd, Italpresse Gauss, Toshiba Machine Co Ltd, Oskar Frech GmbH + Co KG, IDRA Group, Zitai Precision Machinery Co Lt.

3. What are the main segments of the Aluminum Die Casting Machine Market?

The market segments include Machine Type, Industry, Raw Material.

4. Can you provide details about the market size?

The market size is estimated to be USD XX Million as of 2022.

5. What are some drivers contributing to market growth?

Rising Recreational and Motorsports Activities is Expected to Drive the Market; Others.

6. What are the notable trends driving market growth?

Growing Adoption of Aluminum in Die Casting Machinery to Enhance Demand in the Market.

7. Are there any restraints impacting market growth?

High Value and Maintenance Cost Offered to Restrain the Market Growth; Others.

8. Can you provide examples of recent developments in the market?

In May 2022, GF Casting Solutions, a division of GF, Schaffhausen (Switzerland), and the leading light-metal castings and assemblies solutions provider Bocar Group, Mexico City (Mexico), signed an agreement to offer a specialized range of products and services worldwide. The objective of the collaboration is to bring higher value to the customers by combining the capabilities of two leading players in the market for high-pressure die casting components.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Aluminum Die Casting Machine Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Aluminum Die Casting Machine Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Aluminum Die Casting Machine Market?

To stay informed about further developments, trends, and reports in the Aluminum Die Casting Machine Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence