Key Insights

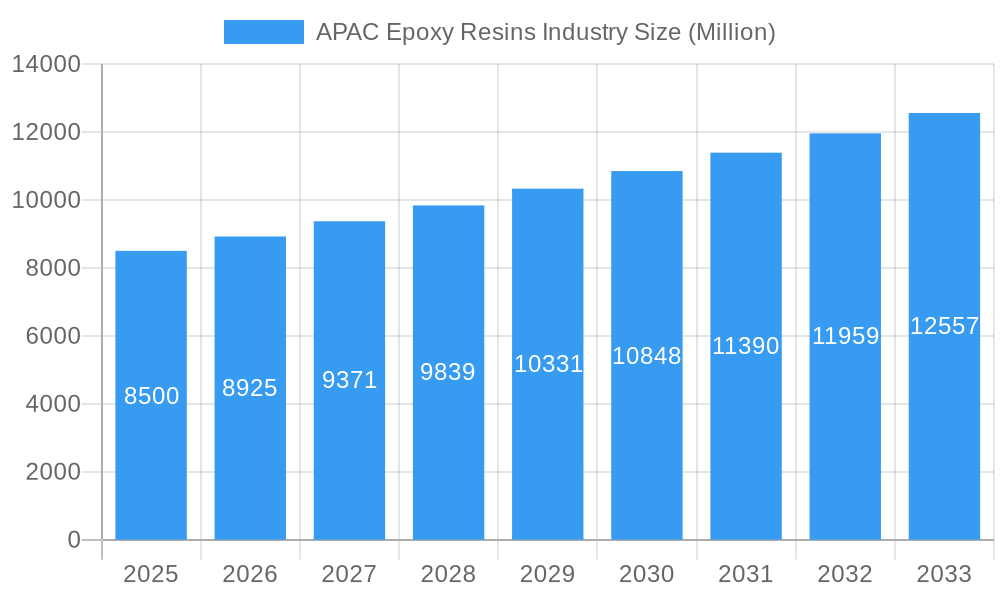

The APAC Epoxy Resins market is poised for robust expansion, driven by a substantial market size and a projected Compound Annual Growth Rate (CAGR) exceeding 5.00%. This growth is fueled by the escalating demand across a multitude of applications, including advanced paints and coatings, high-performance adhesives and sealants, lightweight composites, and critical components in the electrical and electronics sectors. The region's burgeoning industrial landscape, particularly in China, India, and ASEAN countries, is a primary catalyst, supported by significant investments in infrastructure, automotive manufacturing, and renewable energy projects like wind turbines. Key raw materials such as DGBEA (Bisphenol A and ECH) and DGBEF (Bisphenol F and ECH) are expected to witness increased consumption as manufacturers scale up production to meet this rising demand. Innovations in resin formulations and increasing adoption of eco-friendly alternatives are also contributing to the market's positive trajectory.

APAC Epoxy Resins Industry Market Size (In Billion)

Despite the strong growth outlook, certain restraints could influence the market dynamics. Volatility in raw material prices, particularly for key precursors like Bisphenol A and Epichlorohydrin, can impact profitability and necessitate strategic sourcing. Stringent environmental regulations concerning the production and disposal of epoxy resins in some regions may also pose challenges, encouraging a shift towards more sustainable solutions. However, the inherent properties of epoxy resins – their exceptional adhesive strength, chemical resistance, and durability – continue to make them indispensable in various high-value applications. The competitive landscape is characterized by the presence of major global players alongside prominent regional manufacturers, fostering innovation and strategic collaborations to capture market share. The forecast period, spanning from 2019 to 2033 with a focus on the future from 2025 onwards, indicates a sustained upward trend for the APAC Epoxy Resins industry.

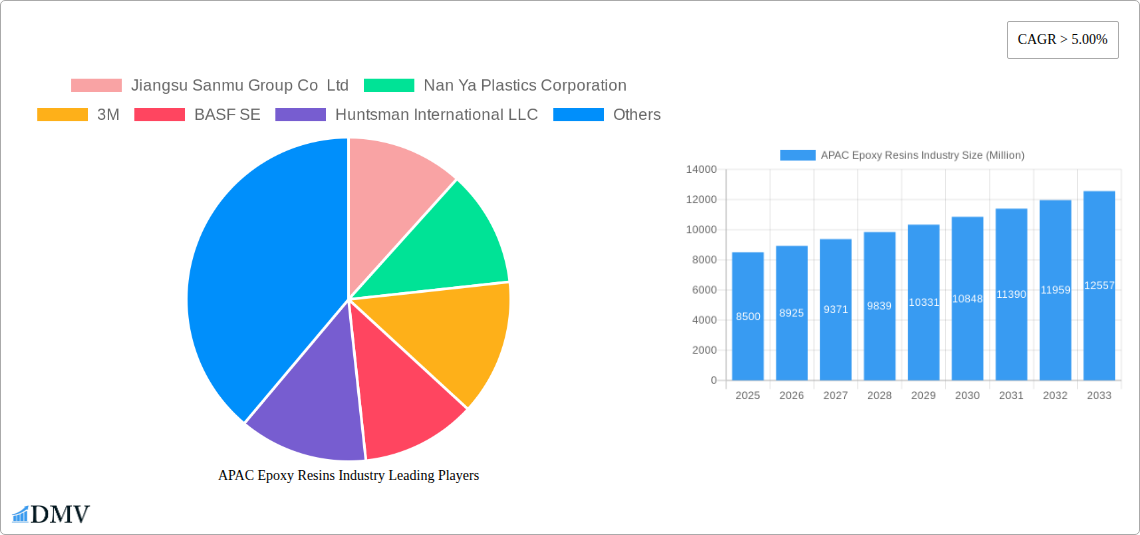

APAC Epoxy Resins Industry Company Market Share

APAC Epoxy Resins Industry Market Composition & Trends

The APAC epoxy resins market is characterized by a moderate to high concentration, with leading global and regional players strategically positioned to capitalize on the region's robust industrial expansion. Innovation catalysts include increasing demand for high-performance materials in burgeoning sectors like electric vehicles and renewable energy, driving significant R&D investments. The regulatory landscape is evolving, with a growing emphasis on environmental sustainability and material safety, influencing product development and manufacturing processes. Substitute products, while present in niche applications, are largely outcompeted by the versatility, durability, and superior performance of epoxy resins, particularly in demanding environments. End-user profiles are diverse, spanning automotive manufacturers seeking lightweight and strong components, construction firms utilizing advanced coatings and adhesives, and electronics giants demanding robust encapsulation and insulation. Mergers and acquisitions (M&A) are a significant trend, with companies aiming to consolidate market share, gain access to new technologies, and expand geographical reach. Estimated M&A deal values in the APAC region are projected to reach approximately $XX Million by 2025, reflecting strategic consolidation and expansion efforts.

- Market Share Distribution: Leading companies like Nan Ya Plastics Corporation and Jiangsu Sanmu Group Co Ltd hold significant market shares, with their influence expected to grow through strategic expansions.

- Innovation Focus: Emphasis on developing bio-based and low-VOC epoxy resins to meet stringent environmental regulations and consumer preferences.

- Regulatory Impact: Stricter REACH-like regulations in key APAC countries are pushing for safer and more sustainable epoxy resin formulations.

- End-User Dynamics: Strong growth driven by the automotive sector's adoption of lightweight composites and advanced coatings, alongside the electronics industry's need for reliable encapsulation.

- M&A Activity: Ongoing consolidation is driven by the pursuit of vertical integration and market dominance.

APAC Epoxy Resins Industry Industry Evolution

The APAC epoxy resins industry has undergone a transformative evolution, marked by consistent market growth and remarkable technological advancements. The historical period from 2019 to 2024 witnessed a steady upward trajectory, fueled by rapid industrialization and escalating infrastructure development across the Asia-Pacific region. The base year of 2025 stands as a pivotal point, with the market projected to reach an estimated value of $XX Billion. This growth is intrinsically linked to the increasing adoption of epoxy resins in diverse applications, from protective coatings and structural adhesives to advanced composites and electrical insulation.

Technological advancements have been a cornerstone of this evolution. The development of novel epoxy resin formulations, including high-solids, waterborne, and UV-curable systems, has enabled manufacturers to meet stringent environmental regulations and cater to specific performance requirements. Innovations in curing agents and additives have further enhanced the properties of epoxy-based materials, leading to improved thermal resistance, chemical inertness, and mechanical strength. The increasing demand for lightweight and durable materials in the automotive and aerospace sectors has spurred the development of advanced epoxy composite systems. Furthermore, the burgeoning wind energy sector's reliance on robust and weather-resistant composite blades has been a significant contributor to market expansion.

Shifting consumer demands, driven by a growing awareness of sustainability and performance, are also reshaping the industry. There is a discernible trend towards the use of epoxy resins in applications that offer extended product lifecycles and reduced environmental impact. For instance, the development of more durable and protective coatings translates to longer-lasting infrastructure and consumer goods, thereby reducing waste. The forecast period from 2025 to 2033 anticipates continued robust growth, with an estimated Compound Annual Growth Rate (CAGR) of XX%. This sustained expansion will be propelled by further technological breakthroughs, such as the development of smart epoxy resins with self-healing capabilities, and the increasing integration of epoxy composites in emerging technologies like electric vehicles and advanced electronics. The adoption metrics for these advanced epoxy systems are expected to rise significantly, indicating a deeper penetration of these materials across various industrial verticals.

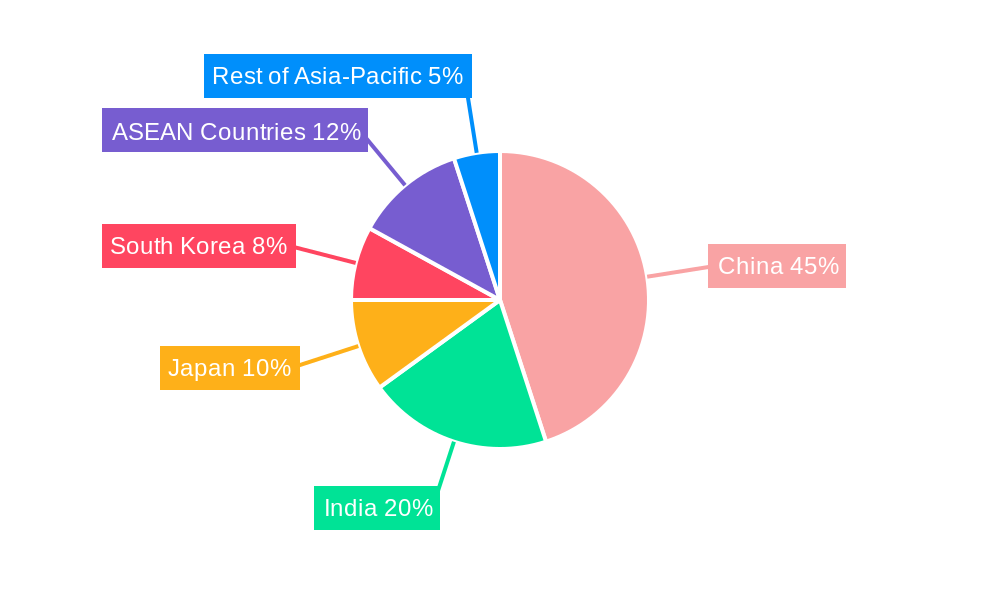

Leading Regions, Countries, or Segments in APAC Epoxy Resins Industry

The APAC epoxy resins industry is largely dominated by China, a powerhouse in manufacturing and consumption. Its expansive industrial base, significant investments in infrastructure, and strong presence in key end-use sectors like electronics, automotive, and construction, firmly establish it as the leading geographical market. The country’s strategic focus on advanced manufacturing and technological development further bolsters its position.

Within the raw material segment, DGBEA (Bisphenol A and ECH) and DGBEF (Bisphenol F and ECH) are pivotal. Their widespread use in the formulation of general-purpose and specialty epoxy resins, catering to a vast array of applications, underscores their market significance. The demand for these raw materials is directly correlated with the growth in paints and coatings, adhesives and sealants, and composite materials.

In terms of applications, Paints and Coatings represent the largest and most influential segment. The relentless demand for protective and decorative coatings in construction, automotive, industrial machinery, and marine applications drives substantial consumption of epoxy resins. Their excellent adhesion, chemical resistance, and durability make them the preferred choice for high-performance coating systems.

Dominant Country - China:

- Key Drivers: Massive domestic demand from construction, automotive, and electronics sectors. Government initiatives supporting manufacturing and R&D in advanced materials. Extensive production capacity for both raw materials and finished epoxy resins.

- Analysis: China's sheer scale of industrial activity and its role as a global manufacturing hub create an insatiable appetite for epoxy resins. Its ability to produce a wide range of epoxy types and formulations efficiently contributes to its market leadership.

Dominant Raw Materials - DGBEA and DGBEF:

- Key Drivers: Versatility in formulating diverse epoxy resin types for broad applications. Cost-effectiveness and availability compared to some specialty raw materials. Essential building blocks for high-performance adhesives, coatings, and composites.

- Analysis: These bisphenol-based epoxy resins are the workhorses of the industry, forming the backbone of numerous products. Their established production infrastructure and performance characteristics ensure their continued dominance.

Dominant Application - Paints and Coatings:

- Key Drivers: Growing infrastructure development globally and within APAC. Increasing need for protective coatings in harsh industrial environments and corrosive conditions. Demand for aesthetically pleasing and durable finishes in consumer goods and vehicles.

- Analysis: The protective and functional capabilities of epoxy-based paints and coatings are indispensable across a wide spectrum of industries, making this segment the primary consumer of epoxy resins.

Other Significant Geographies:

- India: Rapidly growing construction and automotive sectors are fueling demand.

- ASEAN Countries: Emerging economies with increasing industrialization and infrastructure projects.

- Japan and South Korea: Strong presence in high-tech electronics and automotive industries, demanding specialized epoxy resins.

APAC Epoxy Resins Industry Product Innovations

APAC epoxy resins industry is witnessing a surge in product innovations focused on enhancing performance, sustainability, and ease of application. Novel formulations are emerging that offer superior mechanical strength, exceptional thermal stability, and improved chemical resistance for demanding applications in aerospace, automotive, and electrical industries. Advancements in bio-based epoxy resins derived from renewable resources are gaining traction, addressing the growing environmental concerns and offering a greener alternative to traditional petroleum-based products. Furthermore, innovations in waterborne and low-VOC (Volatile Organic Compound) epoxy systems are enabling manufacturers to meet stringent environmental regulations while maintaining high performance standards. The development of faster-curing epoxy systems and one-component formulations is also improving process efficiency for end-users, particularly in high-volume manufacturing environments. These technological advancements are key to unlocking new market opportunities and addressing evolving industry needs.

Propelling Factors for APAC Epoxy Resins Industry Growth

The APAC epoxy resins industry is propelled by a confluence of powerful factors. Rapid industrialization and urbanization across the region drive significant demand for construction materials, protective coatings, and adhesives. The burgeoning automotive sector's increasing adoption of lightweight composite materials for fuel efficiency and performance, coupled with the electrical and electronics industry's need for advanced insulation and encapsulation, are major growth catalysts. Furthermore, government investments in infrastructure development, renewable energy projects like wind turbines, and the expansion of manufacturing capabilities are creating substantial market opportunities. Technological advancements in resin formulation, leading to enhanced performance and environmental sustainability, are also critical in expanding the application scope of epoxy resins.

Obstacles in the APAC Epoxy Resins Industry Market

Despite robust growth, the APAC epoxy resins industry faces several obstacles. Fluctuations in the prices of key raw materials, such as Bisphenol A (BPA) and Epichlorohydrin (ECH), can significantly impact profit margins and product costs. Stringent environmental regulations regarding the use and disposal of certain chemicals, particularly in developed APAC nations, necessitate costly reformulation and compliance efforts. Supply chain disruptions, exacerbated by geopolitical events and logistical challenges, can lead to material shortages and production delays. Intense competition among both global and local players, coupled with the threat of substitute materials in certain less demanding applications, also poses a challenge to market expansion and price stability.

Future Opportunities in APAC Epoxy Resins Industry

The future of the APAC epoxy resins industry is bright with emerging opportunities. The accelerating adoption of electric vehicles (EVs) presents a significant avenue for growth, as epoxy composites are crucial for lightweighting and battery component protection. The expanding renewable energy sector, particularly wind power, requires high-performance epoxy resins for turbine blades. Advancements in 3D printing technology are creating new applications for specialized epoxy resins. Furthermore, the growing demand for sustainable and bio-based materials offers a niche for innovative, eco-friendly epoxy formulations. Increased investment in research and development for advanced composites and smart materials with self-healing or conductive properties will also unlock new market segments.

Major Players in the APAC Epoxy Resins Industry Ecosystem

- Jiangsu Sanmu Group Co Ltd

- Nan Ya Plastics Corporation

- 3M

- BASF SE

- Huntsman International LLC

- Aditya Birla Chemicals

- Daicel Corporation

- Hexion

- Chang Chun Plastics Co Ltd

- Kukdo Chemicals Co Ltd

- Olin Corporation

- Covestro AG

- Atul Ltd

Key Developments in APAC Epoxy Resins Industry Industry

- 2023/07: Jiangsu Sanmu Group Co Ltd announces expansion of its specialty epoxy resin production capacity to meet rising demand from the electronics sector in China.

- 2023/09: Nan Ya Plastics Corporation invests in R&D for bio-based epoxy resins, aiming to launch sustainable product lines in Southeast Asia.

- 2024/01: BASF SE introduces a new range of high-performance epoxy adhesives for the automotive industry, focusing on enhanced bonding strength and durability.

- 2024/03: Huntsman International LLC expands its epoxy resin manufacturing facility in India to cater to the growing infrastructure and construction markets.

- 2024/06: Covestro AG partners with a leading wind turbine manufacturer to develop advanced composite materials using their innovative epoxy resin systems.

Strategic APAC Epoxy Resins Industry Market Forecast

The strategic APAC epoxy resins market is poised for sustained and significant growth through 2033, driven by continuous innovation and expanding application scope. The forecast period will witness an increased focus on high-performance, sustainable, and advanced epoxy resin formulations tailored to meet the evolving demands of key sectors such as electric mobility, renewable energy, and advanced electronics. Emerging market opportunities in infrastructure development, particularly in developing APAC economies, alongside the relentless pursuit of lightweighting and durability in automotive and aerospace industries, will further fuel demand. Strategic investments in R&D and manufacturing capacity, coupled with potential M&A activities aimed at market consolidation and technological integration, will shape the competitive landscape, ensuring a robust and dynamic future for the APAC epoxy resins market.

APAC Epoxy Resins Industry Segmentation

-

1. Raw Material

- 1.1. DGBEA (Bisphenol A and ECH)

- 1.2. DGBEF (Bisphenol F and ECH)

- 1.3. Novolac (Formaldehyde and Phenols)

- 1.4. Aliphatic (Aliphatic Alcohols)

- 1.5. Glycidylamine (Aromatic Amines and ECH)

- 1.6. Other Raw Materials

-

2. Application

- 2.1. Paints and Coatings

- 2.2. Adhesives and Sealants

- 2.3. Composites

- 2.4. Electrical and Electronics

- 2.5. Wind Turbines

- 2.6. Other Applications

-

3. Geography

- 3.1. China

- 3.2. India

- 3.3. Japan

- 3.4. South Korea

- 3.5. ASEAN Countries

- 3.6. Rest of Asia-Pacific

APAC Epoxy Resins Industry Segmentation By Geography

- 1. China

- 2. India

- 3. Japan

- 4. South Korea

- 5. ASEAN Countries

- 6. Rest of Asia Pacific

APAC Epoxy Resins Industry Regional Market Share

Geographic Coverage of APAC Epoxy Resins Industry

APAC Epoxy Resins Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 5.3% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. ; Strong Growth of the Construction Industry; Rising Demand for Electrical and Electronic Devices

- 3.3. Market Restrains

- 3.3.1. ; Hazardous Impact of Epoxy on Health; Impact of COVID-19 Pandemic; Other Restraints

- 3.4. Market Trends

- 3.4.1. Paints and Coatings Segment to Dominate the Market

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global APAC Epoxy Resins Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Raw Material

- 5.1.1. DGBEA (Bisphenol A and ECH)

- 5.1.2. DGBEF (Bisphenol F and ECH)

- 5.1.3. Novolac (Formaldehyde and Phenols)

- 5.1.4. Aliphatic (Aliphatic Alcohols)

- 5.1.5. Glycidylamine (Aromatic Amines and ECH)

- 5.1.6. Other Raw Materials

- 5.2. Market Analysis, Insights and Forecast - by Application

- 5.2.1. Paints and Coatings

- 5.2.2. Adhesives and Sealants

- 5.2.3. Composites

- 5.2.4. Electrical and Electronics

- 5.2.5. Wind Turbines

- 5.2.6. Other Applications

- 5.3. Market Analysis, Insights and Forecast - by Geography

- 5.3.1. China

- 5.3.2. India

- 5.3.3. Japan

- 5.3.4. South Korea

- 5.3.5. ASEAN Countries

- 5.3.6. Rest of Asia-Pacific

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. China

- 5.4.2. India

- 5.4.3. Japan

- 5.4.4. South Korea

- 5.4.5. ASEAN Countries

- 5.4.6. Rest of Asia Pacific

- 5.1. Market Analysis, Insights and Forecast - by Raw Material

- 6. China APAC Epoxy Resins Industry Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Raw Material

- 6.1.1. DGBEA (Bisphenol A and ECH)

- 6.1.2. DGBEF (Bisphenol F and ECH)

- 6.1.3. Novolac (Formaldehyde and Phenols)

- 6.1.4. Aliphatic (Aliphatic Alcohols)

- 6.1.5. Glycidylamine (Aromatic Amines and ECH)

- 6.1.6. Other Raw Materials

- 6.2. Market Analysis, Insights and Forecast - by Application

- 6.2.1. Paints and Coatings

- 6.2.2. Adhesives and Sealants

- 6.2.3. Composites

- 6.2.4. Electrical and Electronics

- 6.2.5. Wind Turbines

- 6.2.6. Other Applications

- 6.3. Market Analysis, Insights and Forecast - by Geography

- 6.3.1. China

- 6.3.2. India

- 6.3.3. Japan

- 6.3.4. South Korea

- 6.3.5. ASEAN Countries

- 6.3.6. Rest of Asia-Pacific

- 6.1. Market Analysis, Insights and Forecast - by Raw Material

- 7. India APAC Epoxy Resins Industry Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Raw Material

- 7.1.1. DGBEA (Bisphenol A and ECH)

- 7.1.2. DGBEF (Bisphenol F and ECH)

- 7.1.3. Novolac (Formaldehyde and Phenols)

- 7.1.4. Aliphatic (Aliphatic Alcohols)

- 7.1.5. Glycidylamine (Aromatic Amines and ECH)

- 7.1.6. Other Raw Materials

- 7.2. Market Analysis, Insights and Forecast - by Application

- 7.2.1. Paints and Coatings

- 7.2.2. Adhesives and Sealants

- 7.2.3. Composites

- 7.2.4. Electrical and Electronics

- 7.2.5. Wind Turbines

- 7.2.6. Other Applications

- 7.3. Market Analysis, Insights and Forecast - by Geography

- 7.3.1. China

- 7.3.2. India

- 7.3.3. Japan

- 7.3.4. South Korea

- 7.3.5. ASEAN Countries

- 7.3.6. Rest of Asia-Pacific

- 7.1. Market Analysis, Insights and Forecast - by Raw Material

- 8. Japan APAC Epoxy Resins Industry Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Raw Material

- 8.1.1. DGBEA (Bisphenol A and ECH)

- 8.1.2. DGBEF (Bisphenol F and ECH)

- 8.1.3. Novolac (Formaldehyde and Phenols)

- 8.1.4. Aliphatic (Aliphatic Alcohols)

- 8.1.5. Glycidylamine (Aromatic Amines and ECH)

- 8.1.6. Other Raw Materials

- 8.2. Market Analysis, Insights and Forecast - by Application

- 8.2.1. Paints and Coatings

- 8.2.2. Adhesives and Sealants

- 8.2.3. Composites

- 8.2.4. Electrical and Electronics

- 8.2.5. Wind Turbines

- 8.2.6. Other Applications

- 8.3. Market Analysis, Insights and Forecast - by Geography

- 8.3.1. China

- 8.3.2. India

- 8.3.3. Japan

- 8.3.4. South Korea

- 8.3.5. ASEAN Countries

- 8.3.6. Rest of Asia-Pacific

- 8.1. Market Analysis, Insights and Forecast - by Raw Material

- 9. South Korea APAC Epoxy Resins Industry Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Raw Material

- 9.1.1. DGBEA (Bisphenol A and ECH)

- 9.1.2. DGBEF (Bisphenol F and ECH)

- 9.1.3. Novolac (Formaldehyde and Phenols)

- 9.1.4. Aliphatic (Aliphatic Alcohols)

- 9.1.5. Glycidylamine (Aromatic Amines and ECH)

- 9.1.6. Other Raw Materials

- 9.2. Market Analysis, Insights and Forecast - by Application

- 9.2.1. Paints and Coatings

- 9.2.2. Adhesives and Sealants

- 9.2.3. Composites

- 9.2.4. Electrical and Electronics

- 9.2.5. Wind Turbines

- 9.2.6. Other Applications

- 9.3. Market Analysis, Insights and Forecast - by Geography

- 9.3.1. China

- 9.3.2. India

- 9.3.3. Japan

- 9.3.4. South Korea

- 9.3.5. ASEAN Countries

- 9.3.6. Rest of Asia-Pacific

- 9.1. Market Analysis, Insights and Forecast - by Raw Material

- 10. ASEAN Countries APAC Epoxy Resins Industry Analysis, Insights and Forecast, 2020-2032

- 10.1. Market Analysis, Insights and Forecast - by Raw Material

- 10.1.1. DGBEA (Bisphenol A and ECH)

- 10.1.2. DGBEF (Bisphenol F and ECH)

- 10.1.3. Novolac (Formaldehyde and Phenols)

- 10.1.4. Aliphatic (Aliphatic Alcohols)

- 10.1.5. Glycidylamine (Aromatic Amines and ECH)

- 10.1.6. Other Raw Materials

- 10.2. Market Analysis, Insights and Forecast - by Application

- 10.2.1. Paints and Coatings

- 10.2.2. Adhesives and Sealants

- 10.2.3. Composites

- 10.2.4. Electrical and Electronics

- 10.2.5. Wind Turbines

- 10.2.6. Other Applications

- 10.3. Market Analysis, Insights and Forecast - by Geography

- 10.3.1. China

- 10.3.2. India

- 10.3.3. Japan

- 10.3.4. South Korea

- 10.3.5. ASEAN Countries

- 10.3.6. Rest of Asia-Pacific

- 10.1. Market Analysis, Insights and Forecast - by Raw Material

- 11. Rest of Asia Pacific APAC Epoxy Resins Industry Analysis, Insights and Forecast, 2020-2032

- 11.1. Market Analysis, Insights and Forecast - by Raw Material

- 11.1.1. DGBEA (Bisphenol A and ECH)

- 11.1.2. DGBEF (Bisphenol F and ECH)

- 11.1.3. Novolac (Formaldehyde and Phenols)

- 11.1.4. Aliphatic (Aliphatic Alcohols)

- 11.1.5. Glycidylamine (Aromatic Amines and ECH)

- 11.1.6. Other Raw Materials

- 11.2. Market Analysis, Insights and Forecast - by Application

- 11.2.1. Paints and Coatings

- 11.2.2. Adhesives and Sealants

- 11.2.3. Composites

- 11.2.4. Electrical and Electronics

- 11.2.5. Wind Turbines

- 11.2.6. Other Applications

- 11.3. Market Analysis, Insights and Forecast - by Geography

- 11.3.1. China

- 11.3.2. India

- 11.3.3. Japan

- 11.3.4. South Korea

- 11.3.5. ASEAN Countries

- 11.3.6. Rest of Asia-Pacific

- 11.1. Market Analysis, Insights and Forecast - by Raw Material

- 12. Competitive Analysis

- 12.1. Global Market Share Analysis 2025

- 12.2. Company Profiles

- 12.2.1 Jiangsu Sanmu Group Co Ltd

- 12.2.1.1. Overview

- 12.2.1.2. Products

- 12.2.1.3. SWOT Analysis

- 12.2.1.4. Recent Developments

- 12.2.1.5. Financials (Based on Availability)

- 12.2.2 Nan Ya Plastics Corporation

- 12.2.2.1. Overview

- 12.2.2.2. Products

- 12.2.2.3. SWOT Analysis

- 12.2.2.4. Recent Developments

- 12.2.2.5. Financials (Based on Availability)

- 12.2.3 3M

- 12.2.3.1. Overview

- 12.2.3.2. Products

- 12.2.3.3. SWOT Analysis

- 12.2.3.4. Recent Developments

- 12.2.3.5. Financials (Based on Availability)

- 12.2.4 BASF SE

- 12.2.4.1. Overview

- 12.2.4.2. Products

- 12.2.4.3. SWOT Analysis

- 12.2.4.4. Recent Developments

- 12.2.4.5. Financials (Based on Availability)

- 12.2.5 Huntsman International LLC

- 12.2.5.1. Overview

- 12.2.5.2. Products

- 12.2.5.3. SWOT Analysis

- 12.2.5.4. Recent Developments

- 12.2.5.5. Financials (Based on Availability)

- 12.2.6 Aditya Birla Chemicals

- 12.2.6.1. Overview

- 12.2.6.2. Products

- 12.2.6.3. SWOT Analysis

- 12.2.6.4. Recent Developments

- 12.2.6.5. Financials (Based on Availability)

- 12.2.7 Daicel Corporation

- 12.2.7.1. Overview

- 12.2.7.2. Products

- 12.2.7.3. SWOT Analysis

- 12.2.7.4. Recent Developments

- 12.2.7.5. Financials (Based on Availability)

- 12.2.8 Hexion

- 12.2.8.1. Overview

- 12.2.8.2. Products

- 12.2.8.3. SWOT Analysis

- 12.2.8.4. Recent Developments

- 12.2.8.5. Financials (Based on Availability)

- 12.2.9 Chang Chun Plastics Co Ltd

- 12.2.9.1. Overview

- 12.2.9.2. Products

- 12.2.9.3. SWOT Analysis

- 12.2.9.4. Recent Developments

- 12.2.9.5. Financials (Based on Availability)

- 12.2.10 Kukdo Chemicals Co Ltd

- 12.2.10.1. Overview

- 12.2.10.2. Products

- 12.2.10.3. SWOT Analysis

- 12.2.10.4. Recent Developments

- 12.2.10.5. Financials (Based on Availability)

- 12.2.11 Olin Corporation*List Not Exhaustive

- 12.2.11.1. Overview

- 12.2.11.2. Products

- 12.2.11.3. SWOT Analysis

- 12.2.11.4. Recent Developments

- 12.2.11.5. Financials (Based on Availability)

- 12.2.12 Covestro AG

- 12.2.12.1. Overview

- 12.2.12.2. Products

- 12.2.12.3. SWOT Analysis

- 12.2.12.4. Recent Developments

- 12.2.12.5. Financials (Based on Availability)

- 12.2.13 Atul Ltd

- 12.2.13.1. Overview

- 12.2.13.2. Products

- 12.2.13.3. SWOT Analysis

- 12.2.13.4. Recent Developments

- 12.2.13.5. Financials (Based on Availability)

- 12.2.1 Jiangsu Sanmu Group Co Ltd

List of Figures

- Figure 1: Global APAC Epoxy Resins Industry Revenue Breakdown (undefined, %) by Region 2025 & 2033

- Figure 2: China APAC Epoxy Resins Industry Revenue (undefined), by Raw Material 2025 & 2033

- Figure 3: China APAC Epoxy Resins Industry Revenue Share (%), by Raw Material 2025 & 2033

- Figure 4: China APAC Epoxy Resins Industry Revenue (undefined), by Application 2025 & 2033

- Figure 5: China APAC Epoxy Resins Industry Revenue Share (%), by Application 2025 & 2033

- Figure 6: China APAC Epoxy Resins Industry Revenue (undefined), by Geography 2025 & 2033

- Figure 7: China APAC Epoxy Resins Industry Revenue Share (%), by Geography 2025 & 2033

- Figure 8: China APAC Epoxy Resins Industry Revenue (undefined), by Country 2025 & 2033

- Figure 9: China APAC Epoxy Resins Industry Revenue Share (%), by Country 2025 & 2033

- Figure 10: India APAC Epoxy Resins Industry Revenue (undefined), by Raw Material 2025 & 2033

- Figure 11: India APAC Epoxy Resins Industry Revenue Share (%), by Raw Material 2025 & 2033

- Figure 12: India APAC Epoxy Resins Industry Revenue (undefined), by Application 2025 & 2033

- Figure 13: India APAC Epoxy Resins Industry Revenue Share (%), by Application 2025 & 2033

- Figure 14: India APAC Epoxy Resins Industry Revenue (undefined), by Geography 2025 & 2033

- Figure 15: India APAC Epoxy Resins Industry Revenue Share (%), by Geography 2025 & 2033

- Figure 16: India APAC Epoxy Resins Industry Revenue (undefined), by Country 2025 & 2033

- Figure 17: India APAC Epoxy Resins Industry Revenue Share (%), by Country 2025 & 2033

- Figure 18: Japan APAC Epoxy Resins Industry Revenue (undefined), by Raw Material 2025 & 2033

- Figure 19: Japan APAC Epoxy Resins Industry Revenue Share (%), by Raw Material 2025 & 2033

- Figure 20: Japan APAC Epoxy Resins Industry Revenue (undefined), by Application 2025 & 2033

- Figure 21: Japan APAC Epoxy Resins Industry Revenue Share (%), by Application 2025 & 2033

- Figure 22: Japan APAC Epoxy Resins Industry Revenue (undefined), by Geography 2025 & 2033

- Figure 23: Japan APAC Epoxy Resins Industry Revenue Share (%), by Geography 2025 & 2033

- Figure 24: Japan APAC Epoxy Resins Industry Revenue (undefined), by Country 2025 & 2033

- Figure 25: Japan APAC Epoxy Resins Industry Revenue Share (%), by Country 2025 & 2033

- Figure 26: South Korea APAC Epoxy Resins Industry Revenue (undefined), by Raw Material 2025 & 2033

- Figure 27: South Korea APAC Epoxy Resins Industry Revenue Share (%), by Raw Material 2025 & 2033

- Figure 28: South Korea APAC Epoxy Resins Industry Revenue (undefined), by Application 2025 & 2033

- Figure 29: South Korea APAC Epoxy Resins Industry Revenue Share (%), by Application 2025 & 2033

- Figure 30: South Korea APAC Epoxy Resins Industry Revenue (undefined), by Geography 2025 & 2033

- Figure 31: South Korea APAC Epoxy Resins Industry Revenue Share (%), by Geography 2025 & 2033

- Figure 32: South Korea APAC Epoxy Resins Industry Revenue (undefined), by Country 2025 & 2033

- Figure 33: South Korea APAC Epoxy Resins Industry Revenue Share (%), by Country 2025 & 2033

- Figure 34: ASEAN Countries APAC Epoxy Resins Industry Revenue (undefined), by Raw Material 2025 & 2033

- Figure 35: ASEAN Countries APAC Epoxy Resins Industry Revenue Share (%), by Raw Material 2025 & 2033

- Figure 36: ASEAN Countries APAC Epoxy Resins Industry Revenue (undefined), by Application 2025 & 2033

- Figure 37: ASEAN Countries APAC Epoxy Resins Industry Revenue Share (%), by Application 2025 & 2033

- Figure 38: ASEAN Countries APAC Epoxy Resins Industry Revenue (undefined), by Geography 2025 & 2033

- Figure 39: ASEAN Countries APAC Epoxy Resins Industry Revenue Share (%), by Geography 2025 & 2033

- Figure 40: ASEAN Countries APAC Epoxy Resins Industry Revenue (undefined), by Country 2025 & 2033

- Figure 41: ASEAN Countries APAC Epoxy Resins Industry Revenue Share (%), by Country 2025 & 2033

- Figure 42: Rest of Asia Pacific APAC Epoxy Resins Industry Revenue (undefined), by Raw Material 2025 & 2033

- Figure 43: Rest of Asia Pacific APAC Epoxy Resins Industry Revenue Share (%), by Raw Material 2025 & 2033

- Figure 44: Rest of Asia Pacific APAC Epoxy Resins Industry Revenue (undefined), by Application 2025 & 2033

- Figure 45: Rest of Asia Pacific APAC Epoxy Resins Industry Revenue Share (%), by Application 2025 & 2033

- Figure 46: Rest of Asia Pacific APAC Epoxy Resins Industry Revenue (undefined), by Geography 2025 & 2033

- Figure 47: Rest of Asia Pacific APAC Epoxy Resins Industry Revenue Share (%), by Geography 2025 & 2033

- Figure 48: Rest of Asia Pacific APAC Epoxy Resins Industry Revenue (undefined), by Country 2025 & 2033

- Figure 49: Rest of Asia Pacific APAC Epoxy Resins Industry Revenue Share (%), by Country 2025 & 2033

List of Tables

- Table 1: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Raw Material 2020 & 2033

- Table 2: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 3: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Geography 2020 & 2033

- Table 4: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Region 2020 & 2033

- Table 5: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Raw Material 2020 & 2033

- Table 6: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 7: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Geography 2020 & 2033

- Table 8: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 9: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Raw Material 2020 & 2033

- Table 10: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 11: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Geography 2020 & 2033

- Table 12: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 13: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Raw Material 2020 & 2033

- Table 14: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 15: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Geography 2020 & 2033

- Table 16: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 17: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Raw Material 2020 & 2033

- Table 18: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 19: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Geography 2020 & 2033

- Table 20: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 21: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Raw Material 2020 & 2033

- Table 22: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 23: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Geography 2020 & 2033

- Table 24: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 25: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Raw Material 2020 & 2033

- Table 26: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 27: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Geography 2020 & 2033

- Table 28: Global APAC Epoxy Resins Industry Revenue undefined Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the APAC Epoxy Resins Industry?

The projected CAGR is approximately 5.3%.

2. Which companies are prominent players in the APAC Epoxy Resins Industry?

Key companies in the market include Jiangsu Sanmu Group Co Ltd, Nan Ya Plastics Corporation, 3M, BASF SE, Huntsman International LLC, Aditya Birla Chemicals, Daicel Corporation, Hexion, Chang Chun Plastics Co Ltd, Kukdo Chemicals Co Ltd, Olin Corporation*List Not Exhaustive, Covestro AG, Atul Ltd.

3. What are the main segments of the APAC Epoxy Resins Industry?

The market segments include Raw Material, Application, Geography.

4. Can you provide details about the market size?

The market size is estimated to be USD XXX N/A as of 2022.

5. What are some drivers contributing to market growth?

; Strong Growth of the Construction Industry; Rising Demand for Electrical and Electronic Devices.

6. What are the notable trends driving market growth?

Paints and Coatings Segment to Dominate the Market.

7. Are there any restraints impacting market growth?

; Hazardous Impact of Epoxy on Health; Impact of COVID-19 Pandemic; Other Restraints.

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in N/A.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "APAC Epoxy Resins Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the APAC Epoxy Resins Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the APAC Epoxy Resins Industry?

To stay informed about further developments, trends, and reports in the APAC Epoxy Resins Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence