Key Insights

The warp knitting machine industry, currently valued at approximately $XX million (estimated based on the provided CAGR of 3.70% and a study period from 2019-2033), is experiencing steady growth driven by increasing demand for high-performance textiles across diverse sectors. The automotive, apparel, and medical industries are key drivers, fueled by the need for lightweight, durable, and specialized fabrics. Technological advancements in warp knitting machinery, including automation and improved efficiency, are further boosting market expansion. The rise of sustainable and eco-friendly production practices is also influencing industry trends, prompting manufacturers to invest in machines that minimize waste and resource consumption. However, factors like high initial investment costs and fluctuating raw material prices pose challenges to market growth. The market is segmented based on machine type (e.g., single-bar, double-bar, multi-bar), application (e.g., apparel, technical textiles, medical textiles), and geographic region. Key players like Karl Mayer, Jakob Muller AG, and Santoni S.p.A. are shaping the competitive landscape through innovations, strategic partnerships, and geographic expansion. The forecast period (2025-2033) anticipates continued growth, albeit at a potentially moderated pace due to economic factors and global supply chain dynamics. The industry is likely to witness increasing consolidation and a focus on offering integrated solutions encompassing machinery, software, and services.

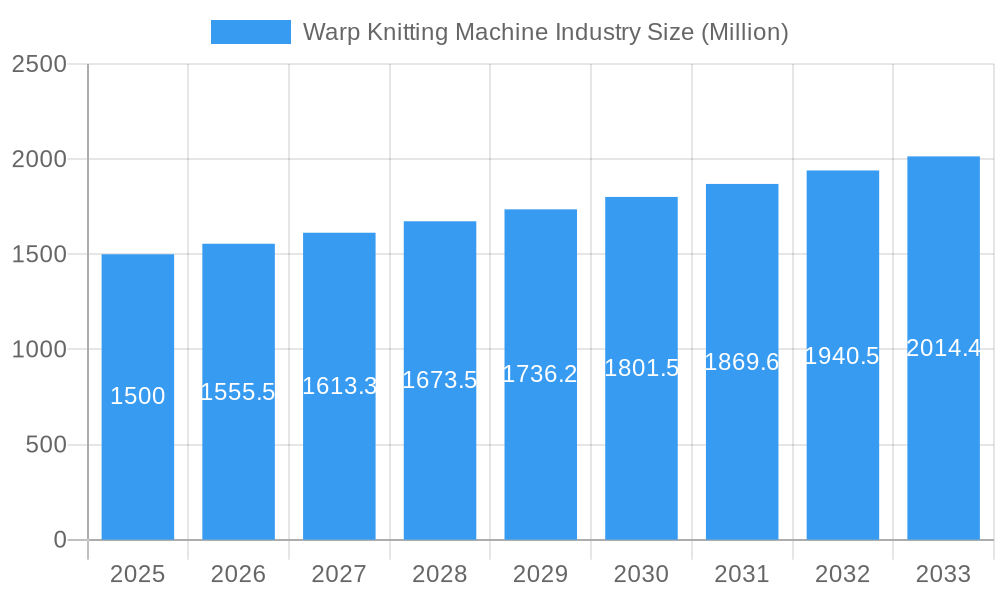

Warp Knitting Machine Industry Market Size (In Billion)

The global warp knitting machine market's projected growth trajectory is influenced by several crucial factors. Stronger demand from emerging economies, coupled with the adoption of advanced technologies in textile manufacturing, contributes to a positive outlook. The integration of Industry 4.0 principles, such as smart manufacturing and data analytics, is reshaping operational efficiency and production capabilities. This transformation presents opportunities for established players to leverage their expertise while also allowing newer entrants to compete on the basis of innovation. However, the potential for trade disruptions and geopolitical instability could impact the supply chain, presenting risks to growth. The market will continue to see innovation in areas such as high-speed knitting, enhanced precision, and improved fabric quality, enhancing the competitiveness and appeal of warp knitting machines for diverse applications. The industry’s future likely involves increased collaborations between machinery manufacturers and textile producers to develop customized solutions tailored to specific market needs.

Warp Knitting Machine Industry Company Market Share

Warp Knitting Machine Industry Market Report: 2019-2033

This comprehensive report provides an in-depth analysis of the global warp knitting machine industry, offering invaluable insights for stakeholders seeking to understand market dynamics, future trends, and investment opportunities. Covering the period 2019-2033, with a base year of 2025 and a forecast period of 2025-2033, this report meticulously examines market size, growth trajectories, technological advancements, and key players. The total market value is projected to reach XX Million by 2033.

Warp Knitting Machine Industry Market Composition & Trends

The global warp knitting machine market exhibits a moderately concentrated structure, with key players such as Karl Mayer, Jakob Muller AG, and Santoni S.p.A. holding significant market share. The exact distribution is complex and varies by segment, but a conservative estimate places the top 5 players at holding approximately 40% of the market. Innovation is a crucial driver, with continuous advancements in machine automation, digitalization (as exemplified by Karl Mayer's KM.ON platform), and material adaptability shaping the competitive landscape. Stringent regulatory frameworks regarding safety and environmental standards further influence industry practices. Substitute products, such as weft knitting machines and non-woven fabric production methods, pose a level of competition, although warp knitting's unique capabilities maintain its significant market position. End-users span diverse sectors including apparel, medical textiles, automotive, and technical textiles. Mergers and acquisitions (M&A) activity remains moderate, with deal values averaging approximately XX Million annually in the historical period (2019-2024), though this number is expected to increase in the coming years.

- Market Share Distribution (Estimated 2025): Top 5 players: 40%; Remaining players: 60%

- Average M&A Deal Value (2019-2024): XX Million

- Key End-User Sectors: Apparel, Medical Textiles, Automotive, Technical Textiles

- Competitive Pressures: Primarily driven by technological advancements and the availability of substitute products.

Warp Knitting Machine Industry Industry Evolution

The warp knitting machine industry has demonstrated robust and consistent growth throughout the historical period of 2019-2024, with an accelerating trajectory projected for the future. This expansion is primarily fueled by relentless technological advancements, particularly in the realms of automation, digitalization, and the seamless integration of Industry 4.0 principles and smart manufacturing solutions. These innovations have not only significantly boosted production efficiency and output but have also elevated product quality to new heights while concurrently driving down operational costs. Furthermore, a discernible shift in consumer preferences towards sustainable, eco-friendly, and technologically advanced textiles has become a powerful catalyst for market expansion. Growth rates have exhibited regional variations and segment-specific performance, with certain segments experiencing impressive double-digit growth, often driven by specific breakthroughs in machinery capabilities. The global market is estimated to have grown at a Compound Annual Growth Rate (CAGR) of xx% between 2019 and 2024. Looking ahead, the industry is poised for continued, if not accelerated, growth through 2033. The increasing adoption of highly automated warp knitting machines across diverse industrial sectors is a significant contributor to this upward market trajectory, directly attributable to enhanced production throughput and a considerable reduction in labor-intensive processes. The projected CAGR for the forecast period of 2025-2033 is anticipated to be within the impressive range of xx%.

Leading Regions, Countries, or Segments in Warp Knitting Machine Industry

The Asia-Pacific region, specifically China, currently holds a dominant position in the warp knitting machine industry. This dominance is driven by several factors:

- Strong Domestic Demand: A large and growing textile industry within the region fuels significant demand for warp knitting machines.

- Cost Advantages: Lower manufacturing costs provide a competitive edge in the global market.

- Government Support: Incentives and supportive policies encourage the growth of the textile manufacturing sector.

- Technological Advancements: Significant investment in R&D contributes to the innovation and improvement of warp knitting machine technology.

While China leads, other regions, including Europe and North America, maintain significant market shares, driven by factors like established textile industries, technological innovation, and consumer demand for high-quality textiles. The European market is characterized by specialized machinery for high-value applications, while North America focuses on automated and high-efficiency machines.

Warp Knitting Machine Industry Product Innovations

Recent and ongoing innovations within the warp knitting machine industry are profoundly reshaping production capabilities. A central theme is the relentless pursuit of heightened automation, sophisticated digitalization powered by cutting-edge smart manufacturing technologies, and an expanded capacity to process an increasingly diverse array of high-performance materials. This encompasses the development of ultra-high-speed machines engineered to meticulously produce intricate patterns and complex designs with unparalleled precision and efficiency. Complementing these hardware advancements are sophisticated software solutions designed for advanced machine control, real-time operational monitoring, and in-depth data analysis. Leading companies such as Karl Mayer are at the vanguard of these transformative developments, consistently delivering innovative solutions that dramatically improve overall production efficiency, minimize material waste, and significantly enhance the final product quality. These groundbreaking innovations are consistently marketed with compelling unique selling propositions that emphasize reduced operational expenditures, substantial increases in productivity, and the delivery of superior end-product quality that meets the most demanding market standards.

Propelling Factors for Warp Knitting Machine Industry Growth

A confluence of powerful factors is driving the sustained growth and evolution of the warp knitting machine industry:

- Pioneering Technological Advancements: The pervasive integration of automation, sophisticated digitalization, and the broader adoption of Industry 4.0 technologies are fundamentally transforming the sector, yielding substantial gains in efficiency, productivity, and operational agility.

- Surging Demand for Specialized and Performance Textiles: The escalating demand for high-performance textiles across critical industries, including the medical sector (e.g., technical textiles for healthcare) and the automotive industry (e.g., advanced materials for vehicle interiors and exteriors), is a significant growth engine.

- Supportive Government Initiatives and Policies: Favorable government policies and strategic initiatives implemented in key economic regions are actively encouraging investment, fostering innovation, and promoting the modernization of the textile machinery sector.

- Global Market Expansion and Emerging Economies: The dynamic growth observed in emerging economies across various continents is continuously creating new and expanding opportunities for market penetration and substantial business expansion for warp knitting machine manufacturers.

- Focus on Sustainability and Circular Economy: An increasing emphasis on environmentally friendly production processes and the development of machines that facilitate the use of recycled and sustainable materials is aligning the industry with global sustainability goals and opening new market segments.

- Customization and On-Demand Manufacturing: The growing trend towards personalized products and on-demand manufacturing necessitates flexible and adaptable warp knitting solutions, driving innovation in machine capabilities and control systems.

Obstacles in the Warp Knitting Machine Industry Market

Challenges hindering industry growth include:

- Supply Chain Disruptions: Global events can lead to unpredictable material shortages and price volatility, affecting production costs.

- Intense Competition: The presence of numerous players, including both established and emerging companies, leads to intense competition on price and innovation.

- Economic Fluctuations: Global economic downturns can negatively impact demand for capital-intensive machinery like warp knitting machines.

- Regulatory Compliance: Adherence to evolving safety and environmental regulations adds complexity and cost to operations.

Future Opportunities in Warp Knitting Machine Industry

Future opportunities include:

- Expansion into Emerging Markets: Untapped markets in developing economies offer significant growth potential.

- Development of Sustainable Technologies: Demand for environmentally friendly manufacturing processes drives innovation in sustainable materials and machine design.

- Integration of Advanced Materials: The use of new materials like high-performance fibers and composites creates new applications for warp knitting machines.

- Focus on Customization and Personalization: Consumers' growing preference for personalized products fuels the demand for flexible and adaptable machines.

Major Players in the Warp Knitting Machine Industry Ecosystem

The warp knitting machine industry is characterized by a competitive landscape featuring established global leaders and emerging innovators. Key entities shaping the market include:

- Karl Mayer - A recognized global leader in warp knitting technology.

- Jakob Muller AG - Specializing in narrow fabric and webbing machinery, with warp knitting applications.

- Santoni S.p.A - Known for its innovative circular and warp knitting solutions.

- Taiwan Giu Chun Ind Co Ltd

- Wuyang Textile Machinery (China) Co Ltd

- Changzhou Runyuan Warp Knitting Machinery Co Ltd

- COMEZ

- Jingwei textile machinery

- Ruanyuan

- Terrot GmbH

- Dukoo Machinery Industry Co

- And a diverse ecosystem of over 63 other specialized companies contributing to the industry's innovation and supply chain.

Key Developments in Warp Knitting Machine Industry Industry

- May 2022: KM.ON, the software company of the KARL MAYER Group, launches further digital solutions to improve customer experience, reduce business complexity, and boost profitability within the textile value chain. This signifies a major push towards digitalization and smart manufacturing within the industry.

- December 2021: Wuyang Textile Machinery successfully appraises three new products: "GE288/5 intelligent cashmere double needle bed warp knitting machine," "GE2290 jacquard warp knitting machine," and "SMJ- CNC Mesh Fabric Warp Knitting Machine." These launches highlight the ongoing innovation in warp knitting machine technology and expansion into new material applications.

Strategic Warp Knitting Machine Industry Market Forecast

The warp knitting machine industry is strategically positioned for a period of sustained and significant growth through the forecast period extending from 2025 to 2033. This optimistic outlook is underpinned by the synergistic forces of continuous technological advancements, a burgeoning global demand for highly specialized and performance-driven textiles, and the successful penetration of new and expanding international markets. The forecast anticipates a substantial expansion in the overall market size, propelled by the ongoing and accelerating adoption of highly automated and digitally integrated warp knitting machines. Furthermore, the increasing industry-wide focus on sustainability, eco-friendly production practices, and the growing consumer demand for customized textile solutions will act as potent drivers for further innovation and market diversification. The total market value is projected to reach an impressive XX Million by the year 2033, signifying robust and lucrative growth opportunities for all stakeholders within the warp knitting machine industry ecosystem.

Warp Knitting Machine Industry Segmentation

-

1. Machine Type

- 1.1. Tricot Knit

- 1.2. Raschel Knit

- 1.3. Crochet Knit

- 1.4. Milanese Knit

-

2. Application

- 2.1. Apparel Textiles

- 2.2. Home Textiles

- 2.3. Technical Textiles

- 2.4. Automotive Textiles

- 2.5. Others

Warp Knitting Machine Industry Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Mexico

-

2. South America

- 2.1. Brazil

- 2.2. Argentina

- 2.3. Rest of South America

-

3. Europe

- 3.1. United Kingdom

- 3.2. Germany

- 3.3. France

- 3.4. Italy

- 3.5. Spain

- 3.6. Russia

- 3.7. Benelux

- 3.8. Nordics

- 3.9. Rest of Europe

-

4. Middle East & Africa

- 4.1. Turkey

- 4.2. Israel

- 4.3. GCC

- 4.4. North Africa

- 4.5. South Africa

- 4.6. Rest of Middle East & Africa

-

5. Asia Pacific

- 5.1. China

- 5.2. India

- 5.3. Japan

- 5.4. South Korea

- 5.5. ASEAN

- 5.6. Oceania

- 5.7. Rest of Asia Pacific

Warp Knitting Machine Industry Regional Market Share

Geographic Coverage of Warp Knitting Machine Industry

Warp Knitting Machine Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 3.70% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 3.4.1. Sports Footwear Creating Demand

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Warp Knitting Machine Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Machine Type

- 5.1.1. Tricot Knit

- 5.1.2. Raschel Knit

- 5.1.3. Crochet Knit

- 5.1.4. Milanese Knit

- 5.2. Market Analysis, Insights and Forecast - by Application

- 5.2.1. Apparel Textiles

- 5.2.2. Home Textiles

- 5.2.3. Technical Textiles

- 5.2.4. Automotive Textiles

- 5.2.5. Others

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. North America

- 5.3.2. South America

- 5.3.3. Europe

- 5.3.4. Middle East & Africa

- 5.3.5. Asia Pacific

- 5.1. Market Analysis, Insights and Forecast - by Machine Type

- 6. North America Warp Knitting Machine Industry Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Machine Type

- 6.1.1. Tricot Knit

- 6.1.2. Raschel Knit

- 6.1.3. Crochet Knit

- 6.1.4. Milanese Knit

- 6.2. Market Analysis, Insights and Forecast - by Application

- 6.2.1. Apparel Textiles

- 6.2.2. Home Textiles

- 6.2.3. Technical Textiles

- 6.2.4. Automotive Textiles

- 6.2.5. Others

- 6.1. Market Analysis, Insights and Forecast - by Machine Type

- 7. South America Warp Knitting Machine Industry Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Machine Type

- 7.1.1. Tricot Knit

- 7.1.2. Raschel Knit

- 7.1.3. Crochet Knit

- 7.1.4. Milanese Knit

- 7.2. Market Analysis, Insights and Forecast - by Application

- 7.2.1. Apparel Textiles

- 7.2.2. Home Textiles

- 7.2.3. Technical Textiles

- 7.2.4. Automotive Textiles

- 7.2.5. Others

- 7.1. Market Analysis, Insights and Forecast - by Machine Type

- 8. Europe Warp Knitting Machine Industry Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Machine Type

- 8.1.1. Tricot Knit

- 8.1.2. Raschel Knit

- 8.1.3. Crochet Knit

- 8.1.4. Milanese Knit

- 8.2. Market Analysis, Insights and Forecast - by Application

- 8.2.1. Apparel Textiles

- 8.2.2. Home Textiles

- 8.2.3. Technical Textiles

- 8.2.4. Automotive Textiles

- 8.2.5. Others

- 8.1. Market Analysis, Insights and Forecast - by Machine Type

- 9. Middle East & Africa Warp Knitting Machine Industry Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Machine Type

- 9.1.1. Tricot Knit

- 9.1.2. Raschel Knit

- 9.1.3. Crochet Knit

- 9.1.4. Milanese Knit

- 9.2. Market Analysis, Insights and Forecast - by Application

- 9.2.1. Apparel Textiles

- 9.2.2. Home Textiles

- 9.2.3. Technical Textiles

- 9.2.4. Automotive Textiles

- 9.2.5. Others

- 9.1. Market Analysis, Insights and Forecast - by Machine Type

- 10. Asia Pacific Warp Knitting Machine Industry Analysis, Insights and Forecast, 2020-2032

- 10.1. Market Analysis, Insights and Forecast - by Machine Type

- 10.1.1. Tricot Knit

- 10.1.2. Raschel Knit

- 10.1.3. Crochet Knit

- 10.1.4. Milanese Knit

- 10.2. Market Analysis, Insights and Forecast - by Application

- 10.2.1. Apparel Textiles

- 10.2.2. Home Textiles

- 10.2.3. Technical Textiles

- 10.2.4. Automotive Textiles

- 10.2.5. Others

- 10.1. Market Analysis, Insights and Forecast - by Machine Type

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2025

- 11.2. Company Profiles

- 11.2.1 Karl Mayer

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Jakob Muller AG

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 Santoni S p A

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 Taiwan Giu Chun Ind Co Ltd

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 Wuyang Textile Machinery (China) Co Ltd

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 Changzhou Runyuan Warp Knitting Machinery Co Ltd

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 COMEZ

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 Jingwei textile machinery

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 Ruanyuan

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 Terrot GmbH

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.11 Dukoo Machinery Industry Co *List Not Exhaustive 6 3 Other Companies (Overview/Key Information

- 11.2.11.1. Overview

- 11.2.11.2. Products

- 11.2.11.3. SWOT Analysis

- 11.2.11.4. Recent Developments

- 11.2.11.5. Financials (Based on Availability)

- 11.2.1 Karl Mayer

List of Figures

- Figure 1: Global Warp Knitting Machine Industry Revenue Breakdown (Million, %) by Region 2025 & 2033

- Figure 2: North America Warp Knitting Machine Industry Revenue (Million), by Machine Type 2025 & 2033

- Figure 3: North America Warp Knitting Machine Industry Revenue Share (%), by Machine Type 2025 & 2033

- Figure 4: North America Warp Knitting Machine Industry Revenue (Million), by Application 2025 & 2033

- Figure 5: North America Warp Knitting Machine Industry Revenue Share (%), by Application 2025 & 2033

- Figure 6: North America Warp Knitting Machine Industry Revenue (Million), by Country 2025 & 2033

- Figure 7: North America Warp Knitting Machine Industry Revenue Share (%), by Country 2025 & 2033

- Figure 8: South America Warp Knitting Machine Industry Revenue (Million), by Machine Type 2025 & 2033

- Figure 9: South America Warp Knitting Machine Industry Revenue Share (%), by Machine Type 2025 & 2033

- Figure 10: South America Warp Knitting Machine Industry Revenue (Million), by Application 2025 & 2033

- Figure 11: South America Warp Knitting Machine Industry Revenue Share (%), by Application 2025 & 2033

- Figure 12: South America Warp Knitting Machine Industry Revenue (Million), by Country 2025 & 2033

- Figure 13: South America Warp Knitting Machine Industry Revenue Share (%), by Country 2025 & 2033

- Figure 14: Europe Warp Knitting Machine Industry Revenue (Million), by Machine Type 2025 & 2033

- Figure 15: Europe Warp Knitting Machine Industry Revenue Share (%), by Machine Type 2025 & 2033

- Figure 16: Europe Warp Knitting Machine Industry Revenue (Million), by Application 2025 & 2033

- Figure 17: Europe Warp Knitting Machine Industry Revenue Share (%), by Application 2025 & 2033

- Figure 18: Europe Warp Knitting Machine Industry Revenue (Million), by Country 2025 & 2033

- Figure 19: Europe Warp Knitting Machine Industry Revenue Share (%), by Country 2025 & 2033

- Figure 20: Middle East & Africa Warp Knitting Machine Industry Revenue (Million), by Machine Type 2025 & 2033

- Figure 21: Middle East & Africa Warp Knitting Machine Industry Revenue Share (%), by Machine Type 2025 & 2033

- Figure 22: Middle East & Africa Warp Knitting Machine Industry Revenue (Million), by Application 2025 & 2033

- Figure 23: Middle East & Africa Warp Knitting Machine Industry Revenue Share (%), by Application 2025 & 2033

- Figure 24: Middle East & Africa Warp Knitting Machine Industry Revenue (Million), by Country 2025 & 2033

- Figure 25: Middle East & Africa Warp Knitting Machine Industry Revenue Share (%), by Country 2025 & 2033

- Figure 26: Asia Pacific Warp Knitting Machine Industry Revenue (Million), by Machine Type 2025 & 2033

- Figure 27: Asia Pacific Warp Knitting Machine Industry Revenue Share (%), by Machine Type 2025 & 2033

- Figure 28: Asia Pacific Warp Knitting Machine Industry Revenue (Million), by Application 2025 & 2033

- Figure 29: Asia Pacific Warp Knitting Machine Industry Revenue Share (%), by Application 2025 & 2033

- Figure 30: Asia Pacific Warp Knitting Machine Industry Revenue (Million), by Country 2025 & 2033

- Figure 31: Asia Pacific Warp Knitting Machine Industry Revenue Share (%), by Country 2025 & 2033

List of Tables

- Table 1: Global Warp Knitting Machine Industry Revenue Million Forecast, by Machine Type 2020 & 2033

- Table 2: Global Warp Knitting Machine Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 3: Global Warp Knitting Machine Industry Revenue Million Forecast, by Region 2020 & 2033

- Table 4: Global Warp Knitting Machine Industry Revenue Million Forecast, by Machine Type 2020 & 2033

- Table 5: Global Warp Knitting Machine Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 6: Global Warp Knitting Machine Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 7: United States Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 8: Canada Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 9: Mexico Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 10: Global Warp Knitting Machine Industry Revenue Million Forecast, by Machine Type 2020 & 2033

- Table 11: Global Warp Knitting Machine Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 12: Global Warp Knitting Machine Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 13: Brazil Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 14: Argentina Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 15: Rest of South America Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 16: Global Warp Knitting Machine Industry Revenue Million Forecast, by Machine Type 2020 & 2033

- Table 17: Global Warp Knitting Machine Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 18: Global Warp Knitting Machine Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 19: United Kingdom Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 20: Germany Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 21: France Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 22: Italy Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 23: Spain Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 24: Russia Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 25: Benelux Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 26: Nordics Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 27: Rest of Europe Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 28: Global Warp Knitting Machine Industry Revenue Million Forecast, by Machine Type 2020 & 2033

- Table 29: Global Warp Knitting Machine Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 30: Global Warp Knitting Machine Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 31: Turkey Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 32: Israel Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 33: GCC Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 34: North Africa Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 35: South Africa Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 36: Rest of Middle East & Africa Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 37: Global Warp Knitting Machine Industry Revenue Million Forecast, by Machine Type 2020 & 2033

- Table 38: Global Warp Knitting Machine Industry Revenue Million Forecast, by Application 2020 & 2033

- Table 39: Global Warp Knitting Machine Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 40: China Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 41: India Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 42: Japan Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 43: South Korea Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 44: ASEAN Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 45: Oceania Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

- Table 46: Rest of Asia Pacific Warp Knitting Machine Industry Revenue (Million) Forecast, by Application 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Warp Knitting Machine Industry?

The projected CAGR is approximately 3.70%.

2. Which companies are prominent players in the Warp Knitting Machine Industry?

Key companies in the market include Karl Mayer, Jakob Muller AG, Santoni S p A, Taiwan Giu Chun Ind Co Ltd, Wuyang Textile Machinery (China) Co Ltd, Changzhou Runyuan Warp Knitting Machinery Co Ltd, COMEZ, Jingwei textile machinery, Ruanyuan, Terrot GmbH, Dukoo Machinery Industry Co *List Not Exhaustive 6 3 Other Companies (Overview/Key Information.

3. What are the main segments of the Warp Knitting Machine Industry?

The market segments include Machine Type, Application.

4. Can you provide details about the market size?

The market size is estimated to be USD XX Million as of 2022.

5. What are some drivers contributing to market growth?

N/A

6. What are the notable trends driving market growth?

Sports Footwear Creating Demand.

7. Are there any restraints impacting market growth?

N/A

8. Can you provide examples of recent developments in the market?

May 2022: KM.ON innovates and digitalizes the textile value chain with its offerings. The software company of the KARL MAYER Group is continuously developing new digital solutions to improve the customer experience, reduce complexity in our customers' day-to-day business and ultimately make their business more profitable.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Warp Knitting Machine Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Warp Knitting Machine Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Warp Knitting Machine Industry?

To stay informed about further developments, trends, and reports in the Warp Knitting Machine Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence