Key Insights

The Metal Fabrication Tools industry is experiencing robust growth, projected to maintain a Compound Annual Growth Rate (CAGR) exceeding 4.30% from 2025 to 2033. This expansion is fueled by several key drivers. Increased automation across manufacturing sectors, particularly in automotive, aerospace, and construction, is significantly boosting demand for advanced metal fabrication tools. The rising adoption of Industry 4.0 technologies, including robotics and AI-powered systems, further enhances efficiency and precision in metal fabrication, driving investment in sophisticated tools. Furthermore, a growing focus on lightweighting in various industries, such as automotive and aerospace, is leading to a demand for tools capable of processing advanced materials and intricate designs. While supply chain disruptions and material cost fluctuations represent potential restraints, the overall industry outlook remains positive, driven by consistent technological advancements and a broadening range of applications.

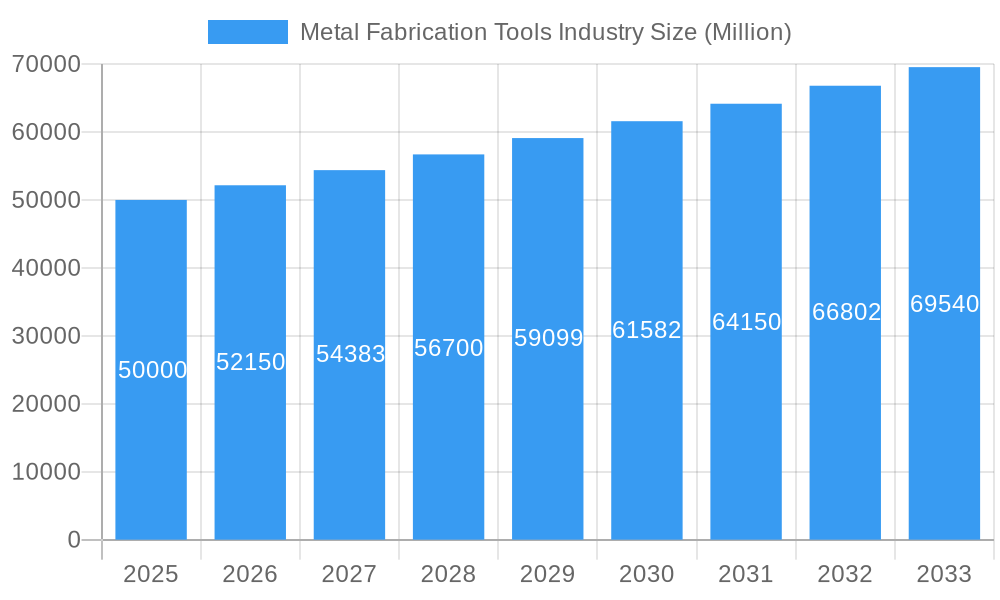

Metal Fabrication Tools Industry Market Size (In Billion)

The market segmentation reveals a diverse landscape with key players such as Trumpf, Shenyang Machine Tool, Amada, Okuma, DMG MORI, FANUC Corp, Colfax, Atlas Copco, and BTD Manufacturing contributing significantly to the overall market value. Regional variations in growth are expected, with regions exhibiting strong industrial growth likely experiencing higher demand for metal fabrication tools. The historical period (2019-2024) likely saw moderate growth, influenced by global economic conditions and technological adoption rates. The forecast period (2025-2033) is poised for significant expansion, driven by the factors mentioned above, leading to a substantial increase in market size and value by 2033. Precise market sizing requires additional data points, however, given the 4.30% CAGR and a 2025 estimated value (let's assume a value of $50 billion for illustrative purposes), a substantial increase in market value is anticipated by 2033. Further analysis based on regional data and specific market segment performance would provide a more comprehensive understanding of the market dynamics.

Metal Fabrication Tools Industry Company Market Share

Metal Fabrication Tools Industry Market Report: 2019-2033

This comprehensive report provides a detailed analysis of the Metal Fabrication Tools industry, offering invaluable insights for stakeholders seeking to understand market dynamics, future trends, and investment opportunities. With a study period spanning 2019-2033, a base year of 2025, and a forecast period of 2025-2033, this report delivers a robust perspective on this dynamic sector. The total market value is predicted to reach xx Million by 2033.

Metal Fabrication Tools Industry Market Composition & Trends

The Metal Fabrication Tools market is characterized by a moderate level of concentration, with key players like Trumpf, Shenyang Machine Tool, Amada, Okuma, DMG MORI, FANUC Corp, Colfax, Atlas Copco, and BTD Manufacturing holding significant market share. However, the market is also witnessing increased competition from smaller, specialized firms. Innovation is driven by the increasing demand for automation, precision, and efficiency in metal fabrication processes. Regulatory landscapes, particularly those concerning safety and environmental standards, significantly impact market players. Substitute products, such as 3D printing technologies, are emerging as potential competitors, although traditional metal fabrication tools continue to hold a dominant position. End-users span various sectors, including automotive, aerospace, construction, and electronics.

Market Share Distribution (Estimated 2025):

- Trumpf: xx%

- Amada: xx%

- DMG MORI: xx%

- Others: xx%

Recent M&A Activities: The industry is witnessing a rise in mergers and acquisitions, with deal values reaching xx Million in the last five years. Notable examples include:

- November 2022: Momentum Manufacturing Group's acquisition of Evans Industries and Little Enterprises, bolstering their semiconductor fabrication capabilities.

- March 2022: Ryerson Holding Corporation's acquisition of Apogee Steel Fabrication Incorporated, strengthening its Canadian operations.

Metal Fabrication Tools Industry Industry Evolution

The Metal Fabrication Tools industry has experienced consistent growth over the historical period (2019-2024), with an average annual growth rate (AAGR) of xx%. This growth is primarily attributed to technological advancements such as the integration of CNC technology, laser cutting, and robotics, enabling greater precision, speed, and automation. Furthermore, increasing demand from key end-user sectors, particularly automotive and aerospace, fueled market expansion. Shifting consumer demands towards lighter, stronger, and more durable materials are also driving innovation in tooling technology. The forecast period (2025-2033) is expected to witness continued growth, driven by factors such as increased adoption of Industry 4.0 technologies and growing investments in infrastructure projects globally. We predict an AAGR of xx% during the forecast period, leading to a market value of xx Million by 2033. Adoption of advanced automation is estimated to increase by xx% annually, while the penetration of laser cutting technology is projected to reach xx% by 2033.

Leading Regions, Countries, or Segments in Metal Fabrication Tools Industry

The Asia-Pacific region currently dominates the metal fabrication tools market, fueled by robust industrial expansion, especially within China and India. This leadership is not merely a matter of scale; it reflects a confluence of factors contributing to a dynamic and rapidly growing market.

Key Drivers for Asia-Pacific Dominance:

- Massive investments in infrastructure projects and manufacturing capacity expansion are creating a significant demand for advanced metal fabrication tools.

- Supportive government policies incentivize industrialization and technological upgrades, fostering a climate conducive to industry growth.

- A large and expanding manufacturing base across diverse sectors—from automotive and electronics to construction and energy—provides a broad customer base for metal fabrication tool suppliers.

- A burgeoning middle class and rising disposable incomes are driving consumer demand for goods that rely on metal fabrication.

While North America and Europe maintain substantial market shares, driven by technological innovation and high adoption rates within advanced manufacturing, the Asia-Pacific region's rapid growth trajectory is projected to solidify its leading position throughout the forecast period. The emergence of other key regions like South America and parts of Africa also presents interesting growth opportunities.

Metal Fabrication Tools Industry Product Innovations

Recent innovations are transforming the metal fabrication landscape, improving efficiency and precision across various processes. This includes the development of:

- Highly efficient and precise laser cutting systems: These systems offer increased cutting speeds, enhanced accuracy, and reduced material waste, leading to significant cost savings.

- Advanced CNC machining centers: These centers boast higher speeds and improved accuracy, enabling the production of complex parts with greater precision and efficiency.

- Robotic automation solutions: Automation is boosting productivity while mitigating labor costs and improving consistency across production runs.

- Improved material handling systems: Optimized material flow reduces bottlenecks and enhances overall production efficiency.

- Enhanced software integration: Sophisticated software solutions provide process optimization, real-time monitoring, and data-driven decision-making capabilities.

- Remote monitoring capabilities: These capabilities enable proactive maintenance, reduce downtime, and improve equipment lifespan.

These innovations deliver unique selling propositions focused on improved speed, precision, and overall efficiency, ultimately enhancing the competitiveness of metal fabrication businesses.

Propelling Factors for Metal Fabrication Tools Industry Growth

Technological advancements, particularly in automation and precision engineering, are a major driver. Economic growth in emerging markets fuels demand for metal fabrication services, while favorable government regulations and incentives support industry expansion. The increasing need for lighter, high-strength materials in sectors like aerospace further stimulates innovation and demand for specialized tools.

Obstacles in the Metal Fabrication Tools Industry Market

Despite significant growth potential, the metal fabrication tools industry faces several challenges:

- Supply chain disruptions: Volatility in the supply of critical raw materials, exacerbated by geopolitical factors and global events, poses a major risk to production and delivery schedules.

- Intense competition: The market is characterized by intense competition amongst both established and emerging players, creating pricing pressure and impacting profit margins.

- Stricter environmental regulations: Increasingly stringent environmental regulations and safety standards necessitate significant investments in compliance measures, potentially increasing production costs.

- Fluctuations in global economic conditions: Economic downturns in key markets can significantly impact demand for metal fabrication tools.

- Skilled labor shortages: The industry faces challenges in attracting and retaining skilled workers to operate and maintain advanced machinery.

Effective management of these obstacles is crucial to sustaining the industry's projected growth trajectory.

Future Opportunities in Metal Fabrication Tools Industry

Emerging markets present significant growth potential, particularly in Africa and South America. The increasing demand for additive manufacturing technologies and the development of sustainable and eco-friendly fabrication processes will shape future opportunities. Specialized tools catering to niche applications and industries will see increased demand.

Major Players in the Metal Fabrication Tools Industry Ecosystem

- Trumpf

- Shenyang Machine Tool

- Amada

- Okuma

- DMG MORI

- FANUC Corp

- Colfax

- Atlas Copco

- BTD Manufacturing

List Not Exhaustive

Key Developments in Metal Fabrication Tools Industry Industry

- November 2022: Momentum Manufacturing Group's acquisition of Evans Industries and Little Enterprises expands its capabilities and market reach into the semiconductor sector.

- March 2022: Ryerson Holding Corporation's acquisition of Apogee Steel Fabrication Incorporated strengthens its value-added services and Canadian market presence.

Strategic Metal Fabrication Tools Industry Market Forecast

The Metal Fabrication Tools industry is poised for continued expansion, propelled by several key factors: technological advancements, growth in end-user sectors (e.g., renewable energy, aerospace, construction), and increased investment in infrastructure globally. The Asia-Pacific region is expected to retain its leading market position, while emerging markets present substantial untapped potential for future growth. The ongoing integration of Industry 4.0 principles, such as automation, data analytics, and connectivity, and the increasing adoption of sustainable manufacturing practices will significantly shape the industry's future trajectory. We project robust growth, with market value exceeding [Insert Projected Market Value] by 2033, driven by a sustained Compound Annual Growth Rate (CAGR) of [Insert Projected CAGR].

Metal Fabrication Tools Industry Segmentation

-

1. Service Type

-

1.1. Machining and Cutting

- 1.1.1. Machining Centres

- 1.1.2. Lathe Machines

- 1.1.3. Drilling, Grinding, Horning, and Lapping Machines

- 1.1.4. Laser, Ion Beam, and Ultrasonic Machines

- 1.1.5. Gear Cutting Machines

- 1.1.6. Sawing and Cutting-off Machines

- 1.1.7. Other Handling and Cutting Equipment

-

1.2. Welding

- 1.2.1. ARC Welding

- 1.2.2. Oxy-fuel Welding

- 1.2.3. Laser Beam Welding

- 1.2.4. Other Types of Welding

-

1.3. Forming

- 1.3.1. Forging Machines and Hammers

- 1.3.2. Bending, Folding, and Straightening Machines

- 1.3.3. Shearing, Punching, and Notching Machines

- 1.3.4. Wire Forming Machines

- 1.3.5. Other Presses and Metal Forming Machines

- 1.4. Other Service Types

-

1.1. Machining and Cutting

-

2. End-user Industries

- 2.1. Automotive

- 2.2. Construction

- 2.3. Aerospace

- 2.4. Electrical and Electronics

- 2.5. Other End-user Industries

Metal Fabrication Tools Industry Segmentation By Geography

- 1. North America

- 2. Latin America

- 3. Asia Pacific

- 4. Europe

- 5. Middle East and Africa

Metal Fabrication Tools Industry Regional Market Share

Geographic Coverage of Metal Fabrication Tools Industry

Metal Fabrication Tools Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of > 4.30% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 3.4.1. Increasing Focus on the Implementation of Industry 4.0

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Metal Fabrication Tools Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Service Type

- 5.1.1. Machining and Cutting

- 5.1.1.1. Machining Centres

- 5.1.1.2. Lathe Machines

- 5.1.1.3. Drilling, Grinding, Horning, and Lapping Machines

- 5.1.1.4. Laser, Ion Beam, and Ultrasonic Machines

- 5.1.1.5. Gear Cutting Machines

- 5.1.1.6. Sawing and Cutting-off Machines

- 5.1.1.7. Other Handling and Cutting Equipment

- 5.1.2. Welding

- 5.1.2.1. ARC Welding

- 5.1.2.2. Oxy-fuel Welding

- 5.1.2.3. Laser Beam Welding

- 5.1.2.4. Other Types of Welding

- 5.1.3. Forming

- 5.1.3.1. Forging Machines and Hammers

- 5.1.3.2. Bending, Folding, and Straightening Machines

- 5.1.3.3. Shearing, Punching, and Notching Machines

- 5.1.3.4. Wire Forming Machines

- 5.1.3.5. Other Presses and Metal Forming Machines

- 5.1.4. Other Service Types

- 5.1.1. Machining and Cutting

- 5.2. Market Analysis, Insights and Forecast - by End-user Industries

- 5.2.1. Automotive

- 5.2.2. Construction

- 5.2.3. Aerospace

- 5.2.4. Electrical and Electronics

- 5.2.5. Other End-user Industries

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. North America

- 5.3.2. Latin America

- 5.3.3. Asia Pacific

- 5.3.4. Europe

- 5.3.5. Middle East and Africa

- 5.1. Market Analysis, Insights and Forecast - by Service Type

- 6. North America Metal Fabrication Tools Industry Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Service Type

- 6.1.1. Machining and Cutting

- 6.1.1.1. Machining Centres

- 6.1.1.2. Lathe Machines

- 6.1.1.3. Drilling, Grinding, Horning, and Lapping Machines

- 6.1.1.4. Laser, Ion Beam, and Ultrasonic Machines

- 6.1.1.5. Gear Cutting Machines

- 6.1.1.6. Sawing and Cutting-off Machines

- 6.1.1.7. Other Handling and Cutting Equipment

- 6.1.2. Welding

- 6.1.2.1. ARC Welding

- 6.1.2.2. Oxy-fuel Welding

- 6.1.2.3. Laser Beam Welding

- 6.1.2.4. Other Types of Welding

- 6.1.3. Forming

- 6.1.3.1. Forging Machines and Hammers

- 6.1.3.2. Bending, Folding, and Straightening Machines

- 6.1.3.3. Shearing, Punching, and Notching Machines

- 6.1.3.4. Wire Forming Machines

- 6.1.3.5. Other Presses and Metal Forming Machines

- 6.1.4. Other Service Types

- 6.1.1. Machining and Cutting

- 6.2. Market Analysis, Insights and Forecast - by End-user Industries

- 6.2.1. Automotive

- 6.2.2. Construction

- 6.2.3. Aerospace

- 6.2.4. Electrical and Electronics

- 6.2.5. Other End-user Industries

- 6.1. Market Analysis, Insights and Forecast - by Service Type

- 7. Latin America Metal Fabrication Tools Industry Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Service Type

- 7.1.1. Machining and Cutting

- 7.1.1.1. Machining Centres

- 7.1.1.2. Lathe Machines

- 7.1.1.3. Drilling, Grinding, Horning, and Lapping Machines

- 7.1.1.4. Laser, Ion Beam, and Ultrasonic Machines

- 7.1.1.5. Gear Cutting Machines

- 7.1.1.6. Sawing and Cutting-off Machines

- 7.1.1.7. Other Handling and Cutting Equipment

- 7.1.2. Welding

- 7.1.2.1. ARC Welding

- 7.1.2.2. Oxy-fuel Welding

- 7.1.2.3. Laser Beam Welding

- 7.1.2.4. Other Types of Welding

- 7.1.3. Forming

- 7.1.3.1. Forging Machines and Hammers

- 7.1.3.2. Bending, Folding, and Straightening Machines

- 7.1.3.3. Shearing, Punching, and Notching Machines

- 7.1.3.4. Wire Forming Machines

- 7.1.3.5. Other Presses and Metal Forming Machines

- 7.1.4. Other Service Types

- 7.1.1. Machining and Cutting

- 7.2. Market Analysis, Insights and Forecast - by End-user Industries

- 7.2.1. Automotive

- 7.2.2. Construction

- 7.2.3. Aerospace

- 7.2.4. Electrical and Electronics

- 7.2.5. Other End-user Industries

- 7.1. Market Analysis, Insights and Forecast - by Service Type

- 8. Asia Pacific Metal Fabrication Tools Industry Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Service Type

- 8.1.1. Machining and Cutting

- 8.1.1.1. Machining Centres

- 8.1.1.2. Lathe Machines

- 8.1.1.3. Drilling, Grinding, Horning, and Lapping Machines

- 8.1.1.4. Laser, Ion Beam, and Ultrasonic Machines

- 8.1.1.5. Gear Cutting Machines

- 8.1.1.6. Sawing and Cutting-off Machines

- 8.1.1.7. Other Handling and Cutting Equipment

- 8.1.2. Welding

- 8.1.2.1. ARC Welding

- 8.1.2.2. Oxy-fuel Welding

- 8.1.2.3. Laser Beam Welding

- 8.1.2.4. Other Types of Welding

- 8.1.3. Forming

- 8.1.3.1. Forging Machines and Hammers

- 8.1.3.2. Bending, Folding, and Straightening Machines

- 8.1.3.3. Shearing, Punching, and Notching Machines

- 8.1.3.4. Wire Forming Machines

- 8.1.3.5. Other Presses and Metal Forming Machines

- 8.1.4. Other Service Types

- 8.1.1. Machining and Cutting

- 8.2. Market Analysis, Insights and Forecast - by End-user Industries

- 8.2.1. Automotive

- 8.2.2. Construction

- 8.2.3. Aerospace

- 8.2.4. Electrical and Electronics

- 8.2.5. Other End-user Industries

- 8.1. Market Analysis, Insights and Forecast - by Service Type

- 9. Europe Metal Fabrication Tools Industry Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Service Type

- 9.1.1. Machining and Cutting

- 9.1.1.1. Machining Centres

- 9.1.1.2. Lathe Machines

- 9.1.1.3. Drilling, Grinding, Horning, and Lapping Machines

- 9.1.1.4. Laser, Ion Beam, and Ultrasonic Machines

- 9.1.1.5. Gear Cutting Machines

- 9.1.1.6. Sawing and Cutting-off Machines

- 9.1.1.7. Other Handling and Cutting Equipment

- 9.1.2. Welding

- 9.1.2.1. ARC Welding

- 9.1.2.2. Oxy-fuel Welding

- 9.1.2.3. Laser Beam Welding

- 9.1.2.4. Other Types of Welding

- 9.1.3. Forming

- 9.1.3.1. Forging Machines and Hammers

- 9.1.3.2. Bending, Folding, and Straightening Machines

- 9.1.3.3. Shearing, Punching, and Notching Machines

- 9.1.3.4. Wire Forming Machines

- 9.1.3.5. Other Presses and Metal Forming Machines

- 9.1.4. Other Service Types

- 9.1.1. Machining and Cutting

- 9.2. Market Analysis, Insights and Forecast - by End-user Industries

- 9.2.1. Automotive

- 9.2.2. Construction

- 9.2.3. Aerospace

- 9.2.4. Electrical and Electronics

- 9.2.5. Other End-user Industries

- 9.1. Market Analysis, Insights and Forecast - by Service Type

- 10. Middle East and Africa Metal Fabrication Tools Industry Analysis, Insights and Forecast, 2020-2032

- 10.1. Market Analysis, Insights and Forecast - by Service Type

- 10.1.1. Machining and Cutting

- 10.1.1.1. Machining Centres

- 10.1.1.2. Lathe Machines

- 10.1.1.3. Drilling, Grinding, Horning, and Lapping Machines

- 10.1.1.4. Laser, Ion Beam, and Ultrasonic Machines

- 10.1.1.5. Gear Cutting Machines

- 10.1.1.6. Sawing and Cutting-off Machines

- 10.1.1.7. Other Handling and Cutting Equipment

- 10.1.2. Welding

- 10.1.2.1. ARC Welding

- 10.1.2.2. Oxy-fuel Welding

- 10.1.2.3. Laser Beam Welding

- 10.1.2.4. Other Types of Welding

- 10.1.3. Forming

- 10.1.3.1. Forging Machines and Hammers

- 10.1.3.2. Bending, Folding, and Straightening Machines

- 10.1.3.3. Shearing, Punching, and Notching Machines

- 10.1.3.4. Wire Forming Machines

- 10.1.3.5. Other Presses and Metal Forming Machines

- 10.1.4. Other Service Types

- 10.1.1. Machining and Cutting

- 10.2. Market Analysis, Insights and Forecast - by End-user Industries

- 10.2.1. Automotive

- 10.2.2. Construction

- 10.2.3. Aerospace

- 10.2.4. Electrical and Electronics

- 10.2.5. Other End-user Industries

- 10.1. Market Analysis, Insights and Forecast - by Service Type

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2025

- 11.2. Company Profiles

- 11.2.1 Trumpf

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Shenyang Machine Tool

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 Amada

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 Okuma

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 DMG MORI

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 FANUC Corp

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 Colfax

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 Atlas Copco

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 BTD Manufacturing**List Not Exhaustive

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.1 Trumpf

List of Figures

- Figure 1: Global Metal Fabrication Tools Industry Revenue Breakdown (Million, %) by Region 2025 & 2033

- Figure 2: North America Metal Fabrication Tools Industry Revenue (Million), by Service Type 2025 & 2033

- Figure 3: North America Metal Fabrication Tools Industry Revenue Share (%), by Service Type 2025 & 2033

- Figure 4: North America Metal Fabrication Tools Industry Revenue (Million), by End-user Industries 2025 & 2033

- Figure 5: North America Metal Fabrication Tools Industry Revenue Share (%), by End-user Industries 2025 & 2033

- Figure 6: North America Metal Fabrication Tools Industry Revenue (Million), by Country 2025 & 2033

- Figure 7: North America Metal Fabrication Tools Industry Revenue Share (%), by Country 2025 & 2033

- Figure 8: Latin America Metal Fabrication Tools Industry Revenue (Million), by Service Type 2025 & 2033

- Figure 9: Latin America Metal Fabrication Tools Industry Revenue Share (%), by Service Type 2025 & 2033

- Figure 10: Latin America Metal Fabrication Tools Industry Revenue (Million), by End-user Industries 2025 & 2033

- Figure 11: Latin America Metal Fabrication Tools Industry Revenue Share (%), by End-user Industries 2025 & 2033

- Figure 12: Latin America Metal Fabrication Tools Industry Revenue (Million), by Country 2025 & 2033

- Figure 13: Latin America Metal Fabrication Tools Industry Revenue Share (%), by Country 2025 & 2033

- Figure 14: Asia Pacific Metal Fabrication Tools Industry Revenue (Million), by Service Type 2025 & 2033

- Figure 15: Asia Pacific Metal Fabrication Tools Industry Revenue Share (%), by Service Type 2025 & 2033

- Figure 16: Asia Pacific Metal Fabrication Tools Industry Revenue (Million), by End-user Industries 2025 & 2033

- Figure 17: Asia Pacific Metal Fabrication Tools Industry Revenue Share (%), by End-user Industries 2025 & 2033

- Figure 18: Asia Pacific Metal Fabrication Tools Industry Revenue (Million), by Country 2025 & 2033

- Figure 19: Asia Pacific Metal Fabrication Tools Industry Revenue Share (%), by Country 2025 & 2033

- Figure 20: Europe Metal Fabrication Tools Industry Revenue (Million), by Service Type 2025 & 2033

- Figure 21: Europe Metal Fabrication Tools Industry Revenue Share (%), by Service Type 2025 & 2033

- Figure 22: Europe Metal Fabrication Tools Industry Revenue (Million), by End-user Industries 2025 & 2033

- Figure 23: Europe Metal Fabrication Tools Industry Revenue Share (%), by End-user Industries 2025 & 2033

- Figure 24: Europe Metal Fabrication Tools Industry Revenue (Million), by Country 2025 & 2033

- Figure 25: Europe Metal Fabrication Tools Industry Revenue Share (%), by Country 2025 & 2033

- Figure 26: Middle East and Africa Metal Fabrication Tools Industry Revenue (Million), by Service Type 2025 & 2033

- Figure 27: Middle East and Africa Metal Fabrication Tools Industry Revenue Share (%), by Service Type 2025 & 2033

- Figure 28: Middle East and Africa Metal Fabrication Tools Industry Revenue (Million), by End-user Industries 2025 & 2033

- Figure 29: Middle East and Africa Metal Fabrication Tools Industry Revenue Share (%), by End-user Industries 2025 & 2033

- Figure 30: Middle East and Africa Metal Fabrication Tools Industry Revenue (Million), by Country 2025 & 2033

- Figure 31: Middle East and Africa Metal Fabrication Tools Industry Revenue Share (%), by Country 2025 & 2033

List of Tables

- Table 1: Global Metal Fabrication Tools Industry Revenue Million Forecast, by Service Type 2020 & 2033

- Table 2: Global Metal Fabrication Tools Industry Revenue Million Forecast, by End-user Industries 2020 & 2033

- Table 3: Global Metal Fabrication Tools Industry Revenue Million Forecast, by Region 2020 & 2033

- Table 4: Global Metal Fabrication Tools Industry Revenue Million Forecast, by Service Type 2020 & 2033

- Table 5: Global Metal Fabrication Tools Industry Revenue Million Forecast, by End-user Industries 2020 & 2033

- Table 6: Global Metal Fabrication Tools Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 7: Global Metal Fabrication Tools Industry Revenue Million Forecast, by Service Type 2020 & 2033

- Table 8: Global Metal Fabrication Tools Industry Revenue Million Forecast, by End-user Industries 2020 & 2033

- Table 9: Global Metal Fabrication Tools Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 10: Global Metal Fabrication Tools Industry Revenue Million Forecast, by Service Type 2020 & 2033

- Table 11: Global Metal Fabrication Tools Industry Revenue Million Forecast, by End-user Industries 2020 & 2033

- Table 12: Global Metal Fabrication Tools Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 13: Global Metal Fabrication Tools Industry Revenue Million Forecast, by Service Type 2020 & 2033

- Table 14: Global Metal Fabrication Tools Industry Revenue Million Forecast, by End-user Industries 2020 & 2033

- Table 15: Global Metal Fabrication Tools Industry Revenue Million Forecast, by Country 2020 & 2033

- Table 16: Global Metal Fabrication Tools Industry Revenue Million Forecast, by Service Type 2020 & 2033

- Table 17: Global Metal Fabrication Tools Industry Revenue Million Forecast, by End-user Industries 2020 & 2033

- Table 18: Global Metal Fabrication Tools Industry Revenue Million Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Metal Fabrication Tools Industry?

The projected CAGR is approximately > 4.30%.

2. Which companies are prominent players in the Metal Fabrication Tools Industry?

Key companies in the market include Trumpf, Shenyang Machine Tool, Amada, Okuma, DMG MORI, FANUC Corp, Colfax, Atlas Copco, BTD Manufacturing**List Not Exhaustive.

3. What are the main segments of the Metal Fabrication Tools Industry?

The market segments include Service Type, End-user Industries.

4. Can you provide details about the market size?

The market size is estimated to be USD XX Million as of 2022.

5. What are some drivers contributing to market growth?

N/A

6. What are the notable trends driving market growth?

Increasing Focus on the Implementation of Industry 4.0.

7. Are there any restraints impacting market growth?

N/A

8. Can you provide examples of recent developments in the market?

November 2022: Momentum Manufacturing Group (MMG), a metal producer, recently acquired two companies that enable the production of semiconductors in order to enter the semiconductor sector. Evans Industries in Topsfield, Massachusetts, and Little Enterprises in Ipswich, Massachusetts, have joined MMG, giving the Georgetown, Massachusetts-based company 86,000 square feet of additional manufacturing space and almost 160 highly qualified team members. Both businesses provide wafer fabrication equipment support components and offer precision metal machining. The purchases will improve MMG's current manufacturing business, which consists of 10 facilities spread throughout New England.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Metal Fabrication Tools Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Metal Fabrication Tools Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Metal Fabrication Tools Industry?

To stay informed about further developments, trends, and reports in the Metal Fabrication Tools Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence