Key Insights

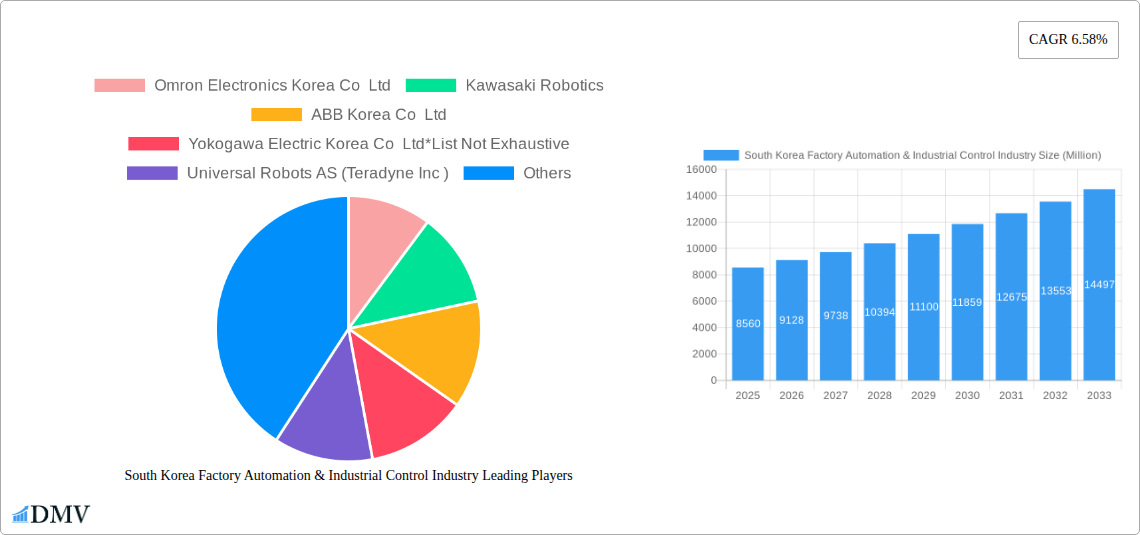

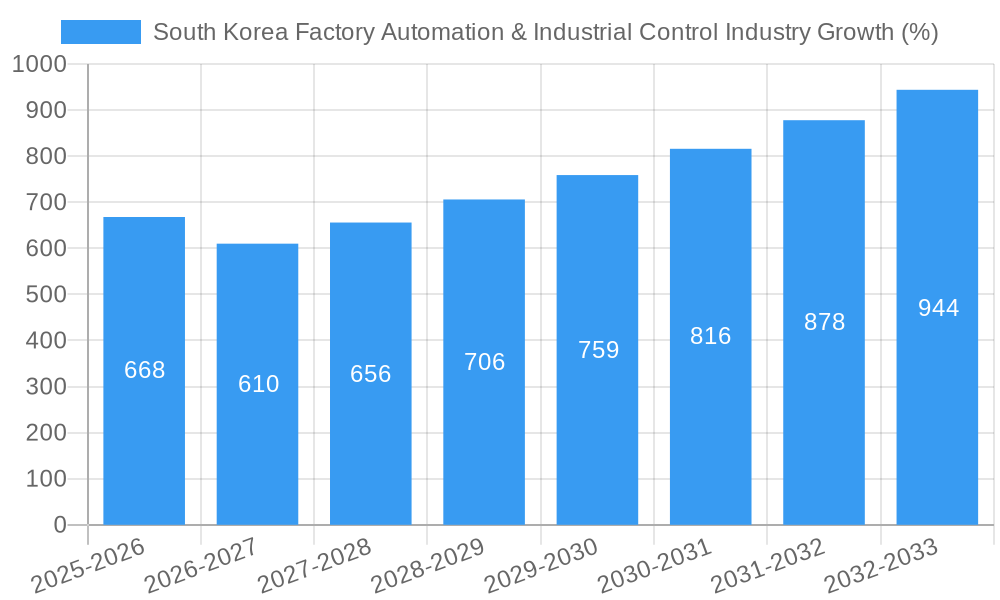

The South Korean factory automation and industrial control market, valued at $8.56 billion in 2025, is projected to experience robust growth, driven by increasing automation adoption across various industries and the government's push for smart factories. A Compound Annual Growth Rate (CAGR) of 6.58% from 2025 to 2033 indicates a significant expansion, with the market expected to exceed $14 billion by 2033. Key drivers include the burgeoning automotive and semiconductor sectors, both significant contributors to South Korea's economy, demanding advanced automation solutions for enhanced efficiency and precision. The rising demand for improved product quality, reduced production costs, and enhanced safety measures further fuels market expansion. Growth is also propelled by technological advancements in areas such as Industrial Internet of Things (IIoT), artificial intelligence (AI), and machine learning (ML), enabling smarter and more responsive factory operations. While challenges such as high initial investment costs and skilled labor shortages exist, the long-term benefits of automation outweigh these hurdles, fostering continuous market expansion.

The market segmentation reveals significant opportunities across diverse product types. Presence sensing safety sensors, emergency stop devices, and safety controllers/modules are crucial components witnessing substantial demand due to stringent safety regulations. The increasing adoption of advanced technologies like programmable logic controllers (PLCs), human-machine interfaces (HMIs), and machine vision systems is also driving growth within these segments. Across end-user industries, the automotive and semiconductor sectors dominate, followed by manufacturing, oil and gas, and chemical industries. The South Korean government's initiatives to promote Industry 4.0 principles and encourage the adoption of advanced manufacturing technologies further solidify the positive outlook for this market. Competitively, established global players alongside robust domestic companies are shaping the landscape. This competitive environment fosters innovation and provides diverse solutions catering to the specific requirements of the South Korean industrial sector.

South Korea Factory Automation & Industrial Control Industry: Market Report 2019-2033

This comprehensive report provides an in-depth analysis of the South Korea Factory Automation & Industrial Control industry, offering invaluable insights for stakeholders across the value chain. Covering the period from 2019 to 2033, with a base year of 2025 and a forecast period from 2025 to 2033, this report meticulously examines market trends, leading players, technological advancements, and future growth prospects. The South Korean factory automation market is projected to reach xx Million by 2033, exhibiting robust growth driven by increasing automation adoption across diverse sectors.

South Korea Factory Automation & Industrial Control Industry Market Composition & Trends

The South Korean factory automation and industrial control market is characterized by a moderately concentrated landscape, with several multinational corporations holding significant market share. The market is witnessing robust innovation, fueled by the country's strong technological capabilities and government support for Industry 4.0 initiatives. Stringent safety regulations and a focus on enhancing operational efficiency drive demand for advanced automation solutions. Substitute products, primarily legacy systems, face increasing competition from more efficient and versatile automated systems. End-users are diversifying across various sectors, with the automotive, semiconductor, and manufacturing sectors currently dominating. M&A activity has been moderate, with deal values averaging xx Million in recent years, reflecting strategic consolidation and expansion efforts.

- Market Share Distribution (2024): Top 5 players hold approximately 40% market share.

- M&A Activity (2019-2024): xx deals concluded, with an average deal value of xx Million.

- Key Innovation Catalysts: Government incentives, R&D investments, and Industry 4.0 initiatives.

- Regulatory Landscape: Stringent safety regulations and standards compliance requirements.

South Korea Factory Automation & Industrial Control Industry Industry Evolution

The South Korean factory automation and industrial control industry has experienced consistent growth over the past five years (2019-2024), with a Compound Annual Growth Rate (CAGR) of xx%. This growth trajectory is projected to continue, albeit at a slightly moderated pace, reaching xx Million by 2033. Technological advancements, including the rise of AI, IoT, and advanced robotics, are pivotal drivers. Consumer demand shifts towards greater efficiency, flexibility, and enhanced safety standards are reshaping the industry landscape. Companies are increasingly adopting collaborative robots (cobots) and smart factory solutions, focusing on data-driven decision making and predictive maintenance.

- Growth Rate (2019-2024): xx% CAGR

- Projected Growth Rate (2025-2033): xx% CAGR

- Adoption of Collaborative Robots (2024): xx% of new industrial robot installations.

- Smart Factory Adoption (2024): xx% of large manufacturing facilities.

Leading Regions, Countries, or Segments in South Korea Factory Automation & Industrial Control Industry

The Gyeonggi-do region currently dominates the South Korean factory automation market, driven by a high concentration of manufacturing facilities and robust technological infrastructure. Among product types, Programmable Logic Controllers (PLCs) and Industrial Robotics hold the largest market share, reflecting their critical role in automation processes. Within end-users, the automotive and semiconductor industries are leading adopters due to their high automation needs and investments in advanced manufacturing technologies.

- Key Drivers (Gyeonggi-do): High concentration of manufacturing plants, robust technological infrastructure, government support.

- Key Drivers (PLCs & Industrial Robotics): Essential components of automation systems, high demand across industries.

- Key Drivers (Automotive & Semiconductor): High automation needs, significant investments in advanced manufacturing.

South Korea Factory Automation & Industrial Control Industry Product Innovations

Recent innovations include the integration of AI-powered predictive maintenance systems, improving operational efficiency and reducing downtime. Advanced sensor technologies provide real-time data for optimized process control. Collaborative robots are gaining traction, enhancing human-machine interaction and fostering safer work environments. These innovations are primarily focused on improving productivity, enhancing safety, and reducing operational costs.

Propelling Factors for South Korea Factory Automation & Industrial Control Industry Growth

The South Korean factory automation market is propelled by several factors: government initiatives promoting Industry 4.0, increasing labor costs encouraging automation adoption, and a strong focus on enhancing manufacturing efficiency. The demand for advanced technologies, such as AI-powered systems and collaborative robots, further fuels market growth. The country's robust technological infrastructure and skilled workforce support the industry's expansion.

Obstacles in the South Korea Factory Automation & Industrial Control Industry Market

High initial investment costs associated with automation solutions can be a barrier for smaller companies. Supply chain disruptions, particularly concerning semiconductor components, have impacted production and delivery timelines. Intense competition among established players and new entrants also poses a challenge. These factors contribute to market volatility and could potentially constrain growth.

Future Opportunities in South Korea Factory Automation & Industrial Control Industry

Emerging opportunities include the growth of the smart factory sector, adoption of advanced analytics for predictive maintenance, and expansion of automation solutions into new industries like healthcare and logistics. The increasing demand for sustainable manufacturing practices presents opportunities for environmentally friendly automation technologies. Expansion into smaller and medium-sized enterprises (SMEs) represents a significant growth potential.

Major Players in the South Korea Factory Automation & Industrial Control Industry Ecosystem

- Omron Electronics Korea Co Ltd

- Kawasaki Robotics

- ABB Korea Co Ltd

- Yokogawa Electric Korea Co Ltd

- Universal Robots AS (Teradyne Inc)

- Honeywell Korea Ltd

- Fuji Electric FA Korea Co Ltd

- Staubli International AG

- Kuka Robotics Korea Co Ltd

- Panasonic Industrial Devices Sales Korea Co Ltd

- Denso Korea Corporation

- Schneider Electric

- Rockwell Automation Inc

- Emerson Electric Korea Ltd

- Mitsubishi Electric Automation Korea Co Ltd

- Korea Fanuc Corporation

- Nidec Corporation

- Epson Korea Co Ltd

- Siemens Korea

- Yaskawa Electric Corporation

Key Developments in South Korea Factory Automation & Industrial Control Industry Industry

- 2022 Q4: Government announces new incentives for smart factory adoption.

- 2023 Q1: ABB Korea launches new range of collaborative robots.

- 2023 Q3: Samsung Electronics invests xx Million in automation upgrades across its facilities.

- 2024 Q2: Omron Electronics Korea partners with a local SME to develop customized automation solutions.

Strategic South Korea Factory Automation & Industrial Control Industry Market Forecast

The South Korean factory automation and industrial control market is poised for continued growth, driven by ongoing technological advancements, government support, and increasing adoption across various industries. The focus on smart factories, collaborative robots, and AI-powered solutions will shape future market dynamics. The market's potential is significant, with opportunities for both established players and new entrants to capitalize on the growing demand for advanced automation technologies.

South Korea Factory Automation & Industrial Control Industry Segmentation

-

1. Product Type

- 1.1. Presence Sensing Safety Sensors

- 1.2. Emergency Stop Devices

- 1.3. Safety Controllers/Modules

- 1.4. Safety Mats

- 1.5. Programmable Logic Controllers (PLC)

- 1.6. Human Machine Interface (HMI)

- 1.7. Machine Vision Systems

- 1.8. Industrial Robotics

- 1.9. Sensors and Transmitters

-

1.10. Switches

- 1.10.1. Safety Switches

- 1.10.2. Limit Switches

- 1.10.3. Pushbutton Switches

- 1.10.4. DIP Switches

- 1.11. Relays

- 1.12. Industrial Power Supplies

-

2. End-user

- 2.1. Automotive

- 2.2. Semiconductor

- 2.3. Manufacturing

- 2.4. Oil and Gas

- 2.5. Chemical and Petrochemical

- 2.6. Food and Beverage

- 2.7. Power and Utilities

- 2.8. Other End-users

South Korea Factory Automation & Industrial Control Industry Segmentation By Geography

- 1. South Korea

South Korea Factory Automation & Industrial Control Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 6.58% from 2019-2033 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Increasing Adoption of Internet of Things (IoT) and Machine-to-Machine Technologies; Increasing Emphasis on Energy Efficiency and Cost Reduction; Exponential Growth of the E-commerce Industry and Customer Expectations

- 3.3. Market Restrains

- 3.3.1. High Up-front Installation Costs and Interoperability Issues; Unavailability for Skilled Workforce

- 3.4. Market Trends

- 3.4.1. Increasing Adoption of Internet of Things (IoT) and Machine-to-Machine Technologies to Drive the Market

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. South Korea Factory Automation & Industrial Control Industry Analysis, Insights and Forecast, 2019-2031

- 5.1. Market Analysis, Insights and Forecast - by Product Type

- 5.1.1. Presence Sensing Safety Sensors

- 5.1.2. Emergency Stop Devices

- 5.1.3. Safety Controllers/Modules

- 5.1.4. Safety Mats

- 5.1.5. Programmable Logic Controllers (PLC)

- 5.1.6. Human Machine Interface (HMI)

- 5.1.7. Machine Vision Systems

- 5.1.8. Industrial Robotics

- 5.1.9. Sensors and Transmitters

- 5.1.10. Switches

- 5.1.10.1. Safety Switches

- 5.1.10.2. Limit Switches

- 5.1.10.3. Pushbutton Switches

- 5.1.10.4. DIP Switches

- 5.1.11. Relays

- 5.1.12. Industrial Power Supplies

- 5.2. Market Analysis, Insights and Forecast - by End-user

- 5.2.1. Automotive

- 5.2.2. Semiconductor

- 5.2.3. Manufacturing

- 5.2.4. Oil and Gas

- 5.2.5. Chemical and Petrochemical

- 5.2.6. Food and Beverage

- 5.2.7. Power and Utilities

- 5.2.8. Other End-users

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. South Korea

- 5.1. Market Analysis, Insights and Forecast - by Product Type

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2024

- 6.2. Company Profiles

- 6.2.1 Omron Electronics Korea Co Ltd

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 Kawasaki Robotics

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 ABB Korea Co Ltd

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 Yokogawa Electric Korea Co Ltd*List Not Exhaustive

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 Universal Robots AS (Teradyne Inc )

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Honeywell Korea Ltd

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 Fuji Electric FA Korea Co Ltd

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 Staubli International AG

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 Kuka Robotics Korea Co Ltd

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.10 Panasonic Industrial Devices Sales Korea Co Ltd

- 6.2.10.1. Overview

- 6.2.10.2. Products

- 6.2.10.3. SWOT Analysis

- 6.2.10.4. Recent Developments

- 6.2.10.5. Financials (Based on Availability)

- 6.2.11 Denso Korea Corporation

- 6.2.11.1. Overview

- 6.2.11.2. Products

- 6.2.11.3. SWOT Analysis

- 6.2.11.4. Recent Developments

- 6.2.11.5. Financials (Based on Availability)

- 6.2.12 Schneider Electric

- 6.2.12.1. Overview

- 6.2.12.2. Products

- 6.2.12.3. SWOT Analysis

- 6.2.12.4. Recent Developments

- 6.2.12.5. Financials (Based on Availability)

- 6.2.13 Rockwell Automation Inc

- 6.2.13.1. Overview

- 6.2.13.2. Products

- 6.2.13.3. SWOT Analysis

- 6.2.13.4. Recent Developments

- 6.2.13.5. Financials (Based on Availability)

- 6.2.14 Emerson Electric Korea Ltd

- 6.2.14.1. Overview

- 6.2.14.2. Products

- 6.2.14.3. SWOT Analysis

- 6.2.14.4. Recent Developments

- 6.2.14.5. Financials (Based on Availability)

- 6.2.15 Mitsubishi Electric Automation Korea Co Ltd

- 6.2.15.1. Overview

- 6.2.15.2. Products

- 6.2.15.3. SWOT Analysis

- 6.2.15.4. Recent Developments

- 6.2.15.5. Financials (Based on Availability)

- 6.2.16 Korea Fanuc Corporation

- 6.2.16.1. Overview

- 6.2.16.2. Products

- 6.2.16.3. SWOT Analysis

- 6.2.16.4. Recent Developments

- 6.2.16.5. Financials (Based on Availability)

- 6.2.17 Nidec Corporation

- 6.2.17.1. Overview

- 6.2.17.2. Products

- 6.2.17.3. SWOT Analysis

- 6.2.17.4. Recent Developments

- 6.2.17.5. Financials (Based on Availability)

- 6.2.18 Epson Korea Co Ltd

- 6.2.18.1. Overview

- 6.2.18.2. Products

- 6.2.18.3. SWOT Analysis

- 6.2.18.4. Recent Developments

- 6.2.18.5. Financials (Based on Availability)

- 6.2.19 Siemens Korea

- 6.2.19.1. Overview

- 6.2.19.2. Products

- 6.2.19.3. SWOT Analysis

- 6.2.19.4. Recent Developments

- 6.2.19.5. Financials (Based on Availability)

- 6.2.20 Yaskawa Electric Corporation

- 6.2.20.1. Overview

- 6.2.20.2. Products

- 6.2.20.3. SWOT Analysis

- 6.2.20.4. Recent Developments

- 6.2.20.5. Financials (Based on Availability)

- 6.2.1 Omron Electronics Korea Co Ltd

List of Figures

- Figure 1: South Korea Factory Automation & Industrial Control Industry Revenue Breakdown (Million, %) by Product 2024 & 2032

- Figure 2: South Korea Factory Automation & Industrial Control Industry Share (%) by Company 2024

List of Tables

- Table 1: South Korea Factory Automation & Industrial Control Industry Revenue Million Forecast, by Region 2019 & 2032

- Table 2: South Korea Factory Automation & Industrial Control Industry Revenue Million Forecast, by Product Type 2019 & 2032

- Table 3: South Korea Factory Automation & Industrial Control Industry Revenue Million Forecast, by End-user 2019 & 2032

- Table 4: South Korea Factory Automation & Industrial Control Industry Revenue Million Forecast, by Region 2019 & 2032

- Table 5: South Korea Factory Automation & Industrial Control Industry Revenue Million Forecast, by Country 2019 & 2032

- Table 6: South Korea Factory Automation & Industrial Control Industry Revenue Million Forecast, by Product Type 2019 & 2032

- Table 7: South Korea Factory Automation & Industrial Control Industry Revenue Million Forecast, by End-user 2019 & 2032

- Table 8: South Korea Factory Automation & Industrial Control Industry Revenue Million Forecast, by Country 2019 & 2032

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the South Korea Factory Automation & Industrial Control Industry?

The projected CAGR is approximately 6.58%.

2. Which companies are prominent players in the South Korea Factory Automation & Industrial Control Industry?

Key companies in the market include Omron Electronics Korea Co Ltd, Kawasaki Robotics, ABB Korea Co Ltd, Yokogawa Electric Korea Co Ltd*List Not Exhaustive, Universal Robots AS (Teradyne Inc ), Honeywell Korea Ltd, Fuji Electric FA Korea Co Ltd, Staubli International AG, Kuka Robotics Korea Co Ltd, Panasonic Industrial Devices Sales Korea Co Ltd, Denso Korea Corporation, Schneider Electric, Rockwell Automation Inc, Emerson Electric Korea Ltd, Mitsubishi Electric Automation Korea Co Ltd, Korea Fanuc Corporation, Nidec Corporation, Epson Korea Co Ltd, Siemens Korea, Yaskawa Electric Corporation.

3. What are the main segments of the South Korea Factory Automation & Industrial Control Industry?

The market segments include Product Type, End-user.

4. Can you provide details about the market size?

The market size is estimated to be USD 8.56 Million as of 2022.

5. What are some drivers contributing to market growth?

Increasing Adoption of Internet of Things (IoT) and Machine-to-Machine Technologies; Increasing Emphasis on Energy Efficiency and Cost Reduction; Exponential Growth of the E-commerce Industry and Customer Expectations.

6. What are the notable trends driving market growth?

Increasing Adoption of Internet of Things (IoT) and Machine-to-Machine Technologies to Drive the Market.

7. Are there any restraints impacting market growth?

High Up-front Installation Costs and Interoperability Issues; Unavailability for Skilled Workforce.

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "South Korea Factory Automation & Industrial Control Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the South Korea Factory Automation & Industrial Control Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the South Korea Factory Automation & Industrial Control Industry?

To stay informed about further developments, trends, and reports in the South Korea Factory Automation & Industrial Control Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence